M10 M12 M16 Male Rod Ends

M10 Rod Ends

Crafted from low carbon steel 230M07PB with zinc plating and color passivation for the housing, bronze SAE660 for the race, and bearing steel 100Ct6 for the ball, they offer low friction and excellent wear resistance. Compliant with ELV and RoHS standards, they operate effectively within a temperature range of -34°C to +149°C. Lubrication is required during installation and periodically thereafter for optimal performance in medium to heavy industrial/mechanical load applications.

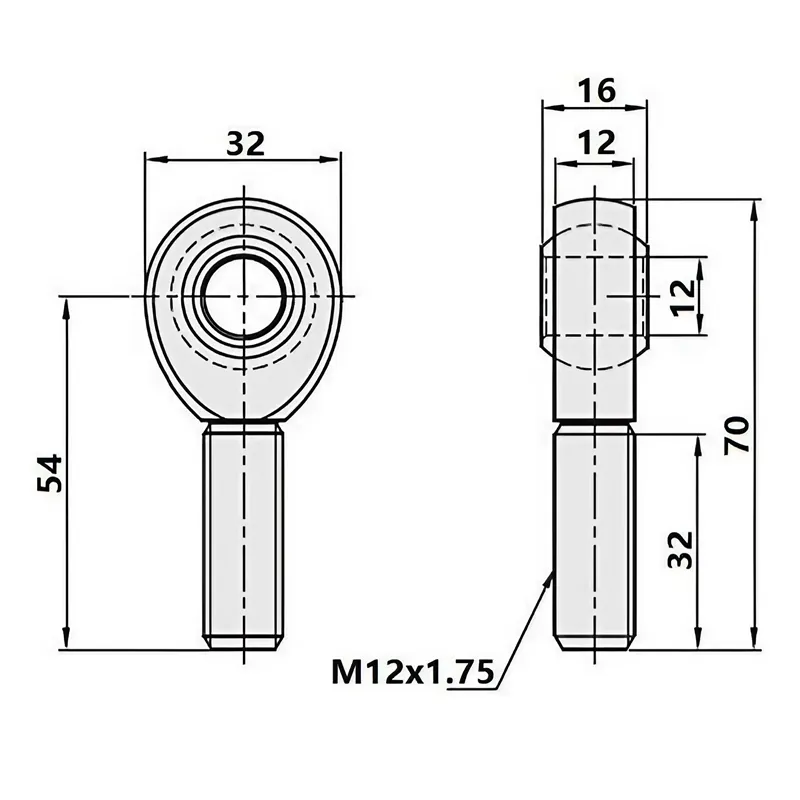

M12 Rod Ends

Featuring a ball pivot with a ball joint that accommodates a bolt or similar hardware, the housing is machined from low-carbon steel and plated for enhanced corrosion resistance.

These shaft end bearings are employed at the extremities of cylinders or rods to compensate for misalignment between two interconnected parts.

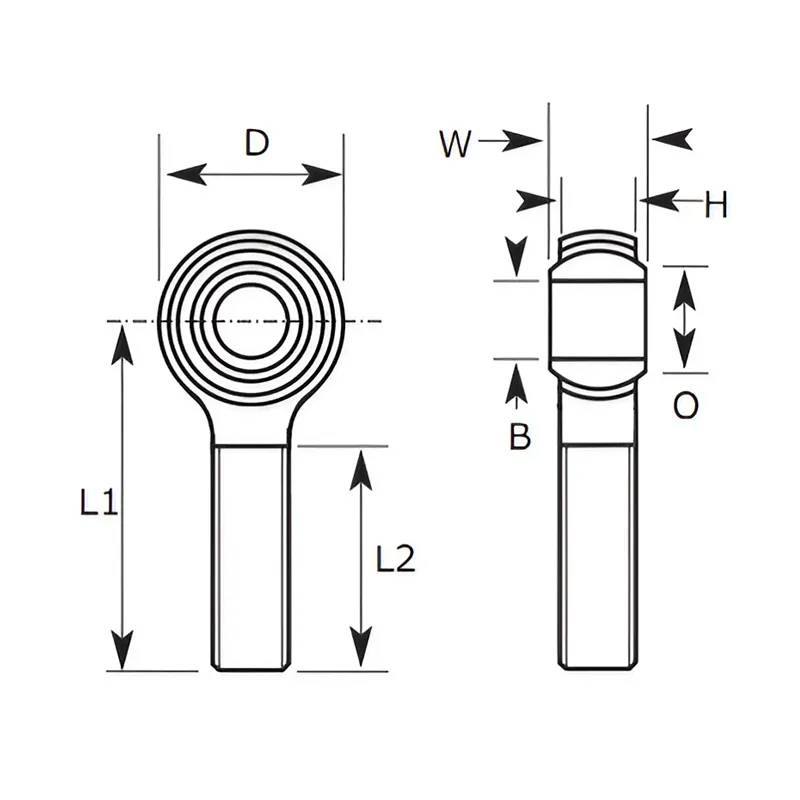

| Bearing number | BRM series,Male Threaded - Rod End Bearing Dimensions mm | kN | Radial clearance mm | Weight Kg | ||||||||||

| d | B | d1 | c1 max | d2 max | G | h1 | L1min | L2 max | a° | Load ratings KN/ Dynamic | Load ratings KN/ Static | |||

| BRM5 | 5 | 8 | 7.6 | 6 | 18 | M5 | 33 | 19 | 42 | 13 | 2.48 | 0.58 | 0.010-0.030 | 0.015 |

| BRM6 | 6 | 9 | 9 | 6.75 | 20 | M6 | 36 | 22 | 46 | 13 | 2.75 | 0.65 | 0.010-0.030 | 0.019 |

| BRM8 | 8 | 12 | 10.5 | 9 | 24 | M8 | 42 | 25 | 54 | 14 | 4 | 1 | 0.010-0.030 | 0.036 |

| BRM10 | 10 | 14 | 12 | 10.5 | 28 | M10 | 48 | 29 | 62 | 13 | 4.45 | 1.45 | 0.010-0.030 | 0.060 |

| BRM12 | 12 | 16 | 14.5 | 12 | 32 | M12 | 54 | 33 | 70 | 13 | 4.95 | 1.8 | 0.010-0.030 | 0.087 |

| BRM14 | 14 | 19 | 17 | 13.5 | 36 | M14 | 60 | 36 | 78 | 16 | 5.6 | 2 | 0.010-0.030 | 0.135 |

| BRM16 | 16 | 21 | 19 | 15 | 42 | M16 | 66 | 40 | 87 | 15 | 6.25 | 2.35 | 0.010-0.030 | 0.190 |

| BRM18 | 18 | 23 | 21.5 | 16.5 | 46 | M18X1.5 | 72 | 44 | 94 | 15 | 7.1 | 2.9 | 0.010-0.030 | 0.270 |

| BRM20 | 20 | 25 | 24.5 | 18 | 50 | M20X1.5 | 78 | 47 | 103 | 14 | 7.9 | 3.45 | 0.010-0.030 | 0.338 |

| BRM22 | 22 | 28 | 26 | 20 | 54 | M22X1.5 | 84 | 51 | 111 | 15 | 9.3 | 3.98 | 0.010-0.030 | 0.450 |

| BRM25 | 25 | 31 | 29.5 | 22 | 64 | M24X2 | 94 | 57 | 124 | 15 | 11.03 | 5.68 | 0.010-0.030 | 0.602 |

| BRM30 | 30 | 37 | 34.5 | 25 | 70 | M30X2 | 110 | 66 | 145 | 17 | 14.15 | 7.45 | 0.010-0.030 | 0.922 |

| BRM35 | 35 | 43 | 37.5 | 28 | 81 | M36X2 | 140 | 85 | 180.5 | 16 | 25 | 12 | 0.010-0.030 | 1.35 |

| BRM40 | 40 | 49 | 45 | 33 | 91 | M42X2 | 150 | 90 | 195.5 | 17 | 35 | 18 | 0.010-0.030 | 1.98 |

| BRM50 | 50 | 60 | 56.2 | 45 | 117 | M48X2 | 185 | 105 | 243.5 | 12 | 52 | 36 | 0.010-0.030 | 4.35 |

M16 Rod Ends

The rod end bearing consists of a standard spherical plain bearing with external threaded shaft. These bearings are capable of simultaneously bearing substantial radial loads and bi-directional axial loads. Featuring a spherical inner ring, the bearing directly contacts the bore surface of the body made from a special bronze alloy. This provides smoother rotation and oscillating movement, thereby improving wear and load characteristics.

Advantages Of Rod End Bearings

Rod end bearings offer several advantages in mechanical systems. They provide articulation and flexibility, enabling smooth rotational movement about multiple axes, facilitating precise motion control across various applications. A key benefit is their ability to accommodate misalignment between mating components, compensating for angular deviations and ensuring reliable performance in challenging conditions. These bearings also distribute loads evenly along their contact surfaces, reducing stress concentration and enhancing load-carrying capacity while minimizing the risk of premature failure or deformation. Moreover, they reduce friction between moving parts, improving efficiency and system performance by minimizing wear and tear. Additionally, rod end bearings possess vibration damping properties, absorbing shocks and dampening vibrations to decrease noise levels, increase stability, and extend system lifespan.

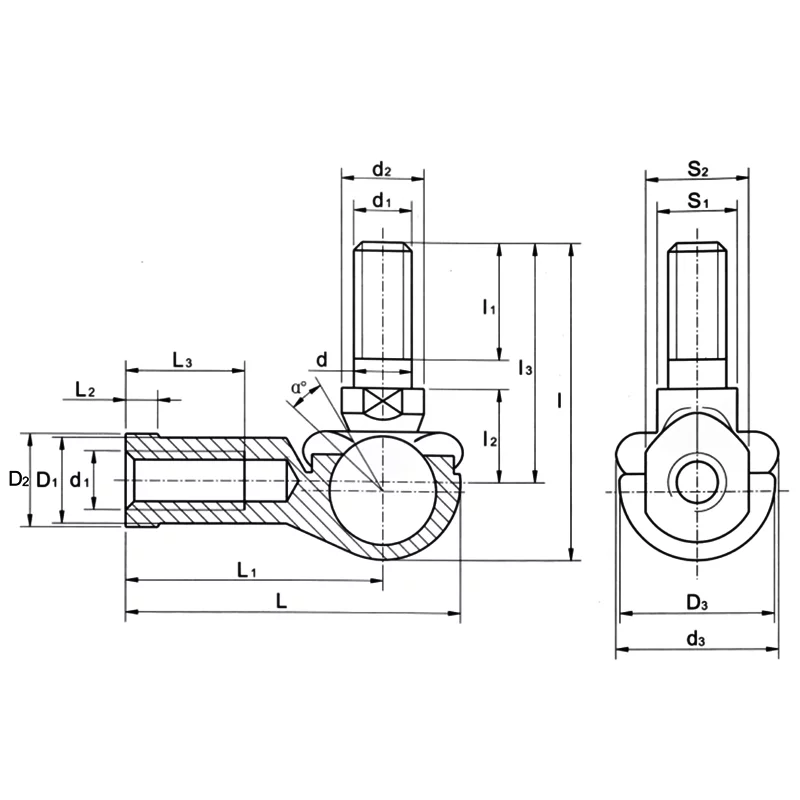

Dimensions in mm

Sliding contact surfaces:Steel/Zinc base alloy

Design and application features:

The shank of ball joint housing may be left-hand thread, for letf-hand thread,

suffix "L" is added tobearing number ar thread sign, e.g.SQL5-RS.

Ball joint housing is made up of zinc base alloy,ball joint shank of carbon steel. It has characteristics

of sell-aligning,wea-resistance and easy mounting,apply to transportation vehicle, packaging machinery.agricultural machinery, etc..