Why do rods use bearings at both ends

Rods often use bearings at both ends for several reasons

1. Reduced Friction: Bearings help to reduce friction between the rod and its mating components.

By incorporating bearings at both ends, the rotational movement of the rod becomes smoother and more efficient.

This reduction in friction minimizes wear and tear on the rod and its connected parts, leading to improved longevity and performance.

2. Improved Load Distribution: Bearings distribute the load evenly along the length of the rod.

When a load is applied to one end of the rod, the bearings help to transmit and distribute that

load across their contact surfaces, preventing excessive stress concentration at a single point.

This ensures better load-carrying capacity and helps prevent premature failure or deformation of the rod.

3. Misalignment Compensation: Bearings can accommodate misalignment between mating components or

angular deviations in motion paths. By allowing slight rotational movement or articulation,

they compensate for any misalignment that may occur during operation due to manufacturing tolerances,

thermal expansion, or dynamic forces acting on the system.

4. Vibration Damping: Bearings contribute to damping vibrations generated during operation by absorbing

shocks or oscillations transmitted through the rod. This helps to minimize vibration-related

issues such as noise, fatigue, or resonance that could negatively impact system performance or cause damage over time.

5. Precise Positioning: Using bearings at both ends enables precise positioning control of the rod

within its assembly or system. The bearings provide stable support and maintain accurate alignment

between connected components, ensuring proper functioning and reliable operation.

6. Versatility in Design: Incorporating bearings at both ends allows for greater flexibility in

design choices for connecting rods in various applications. It enables engineers to optimize performance

by selecting different types of bearings (such as plain bearings, ball joints, or roller bearings)

based on specific requirements related to load capacity, speed, lubrication needs, environmental conditions, etc.

7. Reduced Maintenance: With bearings at both ends, maintenance requirements are typically reduced compared to alternative setups. Properly lubricated and maintained bearings can operate for extended periods without needing frequent attention or replacement. This lowers downtime and maintenance costs, contributing to overall cost-effectiveness and operational efficiency of the system employing the rods.

8. Enhanced Efficiency: The use of bearings facilitates smoother motion transmission, which can lead to enhanced overall efficiency of the system. With reduced friction and optimized load distribution, less energy is wasted in overcoming resistance or uneven loading, resulting in improved energy efficiency and potentially lower operating costs over the long term.

9. Compatibility with Lubrication Systems: Bearings are often compatible with various lubrication systems, allowing for effective lubrication to be applied to critical contact points. Proper lubrication helps to further reduce friction, minimize wear, and extend the service life of both the bearings and the connected components, ensuring reliable performance over time.

10. Resistance to Corrosion and Contamination: Many bearing designs incorporate features that provide resistance to corrosion and contamination. This is particularly important in harsh operating environments where exposure to moisture, dirt, chemicals, or other contaminants could compromise performance and durability. By protecting against such factors, bearings help to maintain the integrity and functionality of the rods and their associated components, even in challenging conditions.

Overall, the utilization of bearings at both ends of rods offers numerous advantages that contribute to the reliability, performance, and longevity of mechanical systems across various industries and applications.

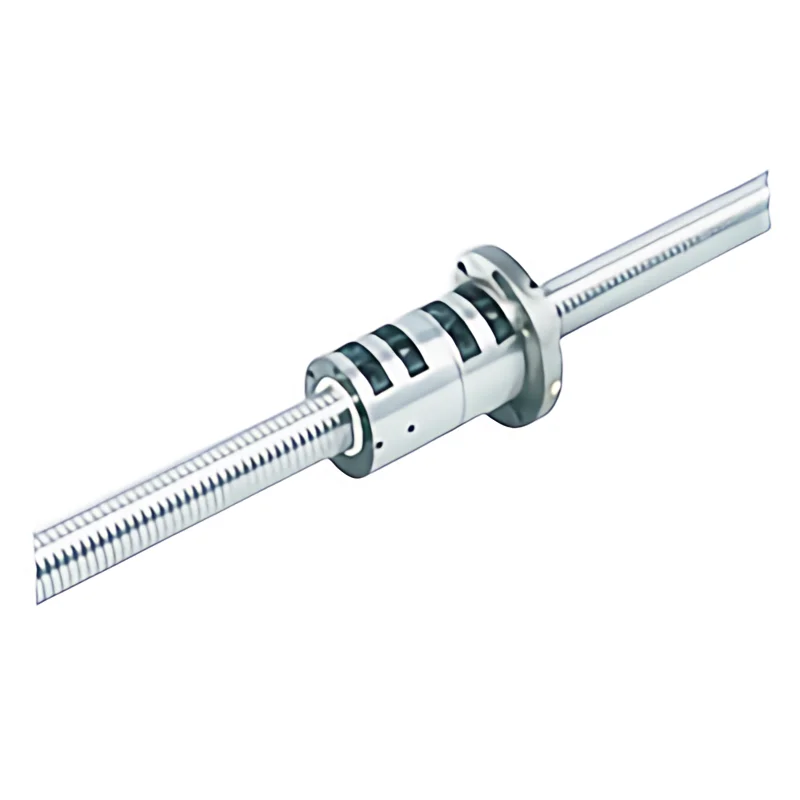

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

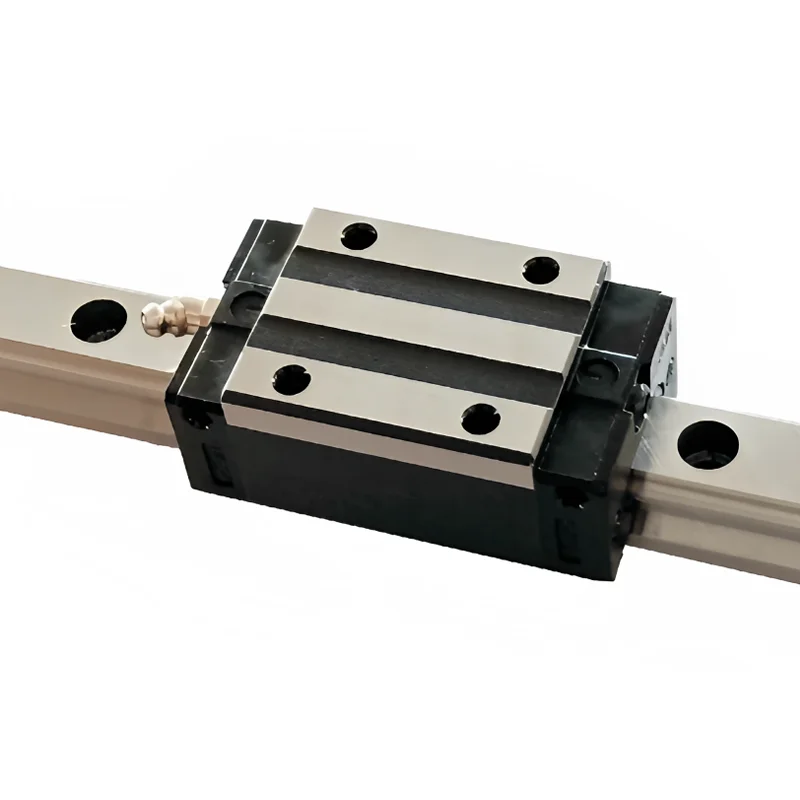

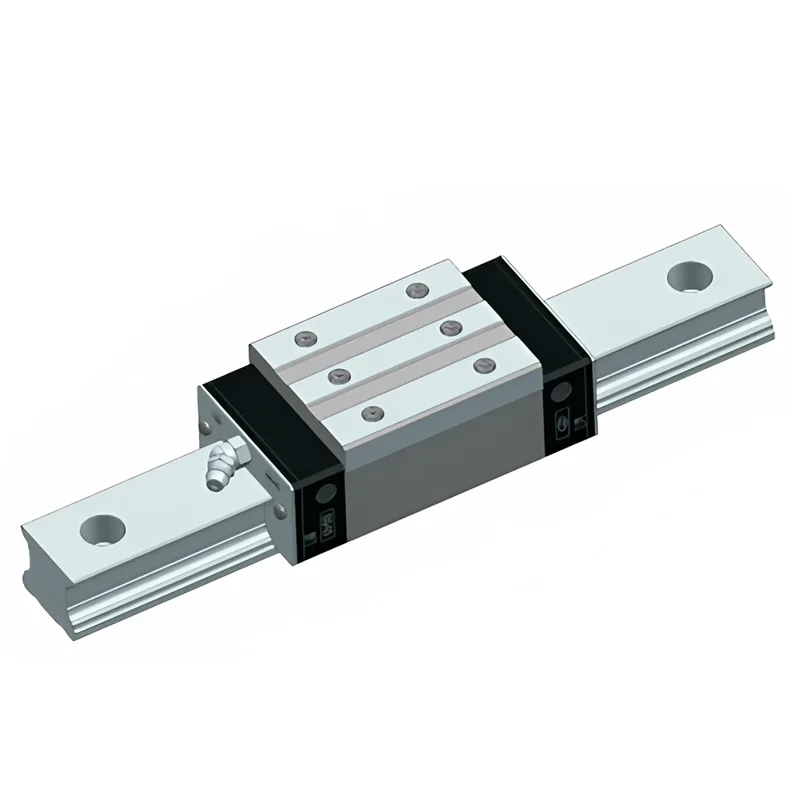

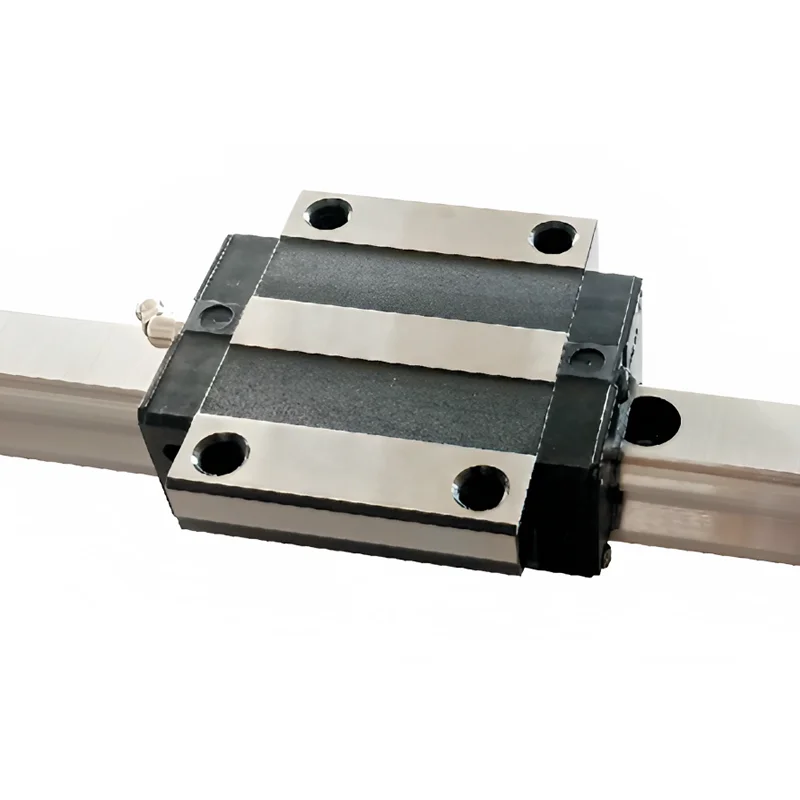

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS