Understanding Ball Screws: Essential Components for Precise Linear Motion in Industrial Automation

Ball Screws are a key component in modern industrial automation, robotics, and precision machinery.

These mechanical devices convert rotary motion into linear motion, offering high efficiency, precision,

and durability. In various applications like CNC machining, robotics, and automation,

ball screws play a crucial role in achieving high-speed, accurate, and repeatable motion.

Composition and Characteristics of Ball Screws

Ball screws are typically made up of several core components, including the screw shaft, ball nut, and ball bearings.

Common sizes such as 1500mm, 2500mm, and 3000mm offer versatile solutions for different automation systems.

The screw shaft is typically constructed from chromium-molybdenum steel, a material known for its strength, durability,

and resistance to wear. The ball nuts are often made from brass or steel, providing excellent load distribution and ensuring high positioning accuracy.

One of the most prominent features of ball screws is their low starting torque.

This means that very little force is needed to initiate linear motion, making them highly efficient for applications requiring fine,

high-speed movements. Due to this low friction resistance, ball screws are widely used in precision instruments, industrial machinery,

and robotics, where accuracy and speed are paramount.

Stainless Steel Ball Screws: Enhanced Durability and Corrosion Resistance

For demanding environments, stainless steel ball screws are an ideal solution.

They are specifically designed to offer exceptional positioning accuracy and repeatability, even under harsh operating conditions.

The corrosion resistance of stainless steel ensures that these ball screws maintain their reliability over time,

even in environments exposed to moisture, chemicals, or extreme temperatures.

Stainless steel ball screws are commonly used in applications that require sterile conditions or those that involve contact with harsh substances.

Their ability to resist corrosion ensures that they maintain their efficiency and performance over long periods of use,

making them an essential part of the automation systems in the food, pharmaceutical, and medical industries.

Ball Screw Materials: Ensuring Efficiency and Reliability

The performance of a ball screw is heavily dependent on the materials used in its construction.

The screw shaft, typically made of chromium-molybdenum steel, provides the strength needed to withstand heavy loads and stress during operation.

Brass or steel ball nuts are used to ensure precise movement, while high-grade bearing steel or ceramic balls help reduce friction,

contributing to the smoothness and efficiency of motion.

The primary advantage of ball screws lies in their ability to convert rotary motion into linear motion or axial repetitive force with high precision.

Their low friction resistance minimizes energy losses and ensures long-term durability, even in the most demanding applications.

Applications of Ball Screws

Ball screws are used in a wide range of industrial applications, particularly in systems that require precise motion control.

They are integral to the operation of CNC machines, robotics, and automation systems, where both speed and accuracy are critical.

Their ability to handle high loads while maintaining high efficiency makes them indispensable in industries such as manufacturing, automotive, aerospace,

and medical technology.

Due to their high precision and reversibility, ball screws are often used in systems where fine adjustments and repeatable performance are needed.

This includes applications such as laser cutting, 3D printing, and automated assembly lines, where precision is key to ensuring quality and consistency.

Conclusion

Ball screws are essential components for achieving high-precision linear motion in a wide array of industrial and robotic applications.

Their unique composition, which includes materials such as chromium-molybdenum steel and stainless steel, ensures strength, durability,

and corrosion resistance. With their low starting torque, ball screws enable fast, efficient, and repeatable motion,

making them ideal for industries requiring high-speed automation.

For more information on ball screws and how they can enhance your automation systems, contact Ningbo SAIVS Machinery Co., Ltd.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

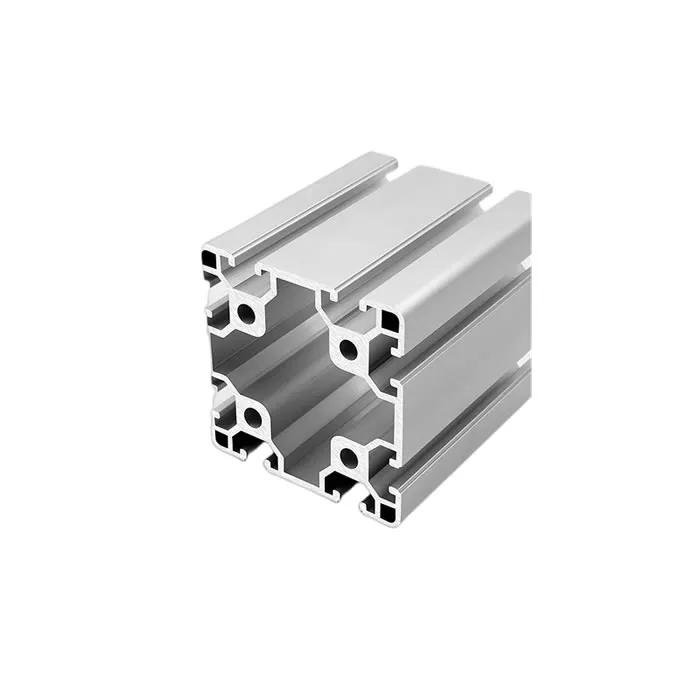

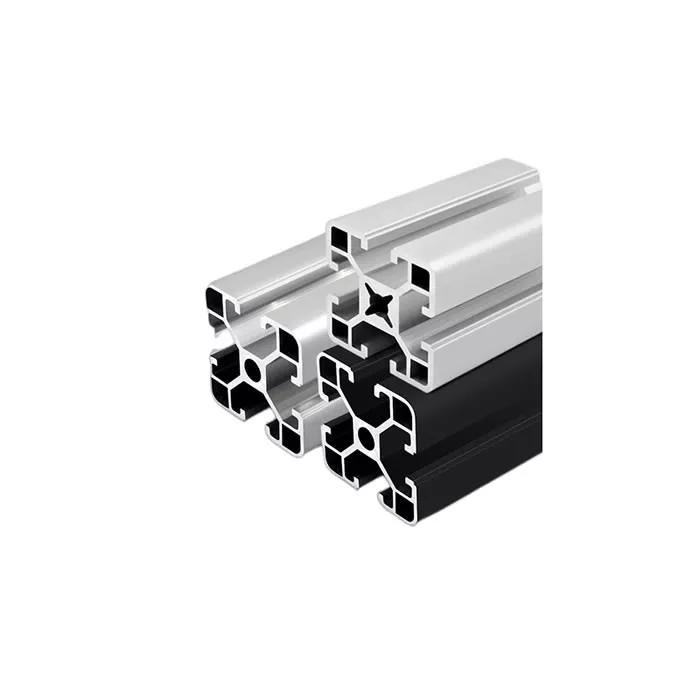

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS