Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

In the fast-evolving world of industrial automation, precision and efficiency are critical.

One of the most essential mechanical components that enable accurate linear motion in modern systems is the Ball Screw.

At Ningbo SAIVS Machinery Co., Ltd., we specialize in providing high-quality ball screws that deliver superior performance across various demanding industries.

What Are Ball Screws and Why Are They Important?

Ball screws are mechanical devices that convert rotary motion into linear motion with minimal friction.

Unlike traditional lead screws, ball screws use ball bearings to reduce friction between the screw shaft and the nut.

This design significantly improves efficiency and accuracy, making them indispensable in CNC machines, robotics, aerospace systems, and medical devices.

One of the primary reasons ball screws are widely used in industrial applications is their low starting torque, which allows for smooth and fast movements with minimal power consumption. This efficiency is crucial for industries where precise, repeatable positioning is essential.

Materials and Composition: Designed for Strength and Longevity

At SAIVS, we manufacture ball screws using top-grade materials such as chromium-molybdenum steel for the screw shaft, known for its exceptional strength and resistance to wear. Ball nuts are typically made from brass or high-grade steel, ensuring durability under heavy loads and maintaining accurate positioning over extended usage.

For specialized environments, such as those involving exposure to moisture, chemicals, or sterilized conditions, we offer stainless steel ball screws. These are engineered to deliver high corrosion resistance and are ideal for industries like pharmaceuticals, food processing, and medical equipment manufacturing.

Our most popular sizes include 1500mm, 2500mm, and 3000mm, suitable for a wide range of applications and customizable based on your machinery requirements.

Performance Benefits: Why Engineers Prefer Ball Screws

High efficiency: Up to 90% mechanical efficiency thanks to the rolling motion of ball bearings.

Precision and repeatability: Ideal for applications requiring micrometer-level control.

Long service life: Materials and design choices reduce wear and tear, resulting in longer operational cycles.

Versatile applications: From 3D printing and laser cutting to robotic arms and automated production lines.

These advantages make ball screws the preferred solution for businesses aiming to increase automation, reduce energy costs, and improve product quality through better motion control.

Why Choose SAIVS as Your Ball Screw Supplier?

When purchasing ball screws, quality and reliability should be top priorities.

At SAIVS, we combine advanced manufacturing techniques with rigorous quality control to ensure every ball screw meets international standards. We offer:

Competitive factory-direct prices

Custom design and material options

Quick global shipping

Responsive technical support

Our solutions are trusted by engineers, OEMs, and procurement professionals worldwide who seek long-term performance and excellent ROI on their automation components.

Request a Quote or Consultation Today

Whether you're upgrading an existing system or developing a new piece of precision equipment, Ningbo SAIVS Machinery Co., Ltd. is ready to help.

Contact us today to learn more about our ball screw selection or to request a custom quote.

How to avoid roller bearing failures

How to avoid roller bearing failures

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

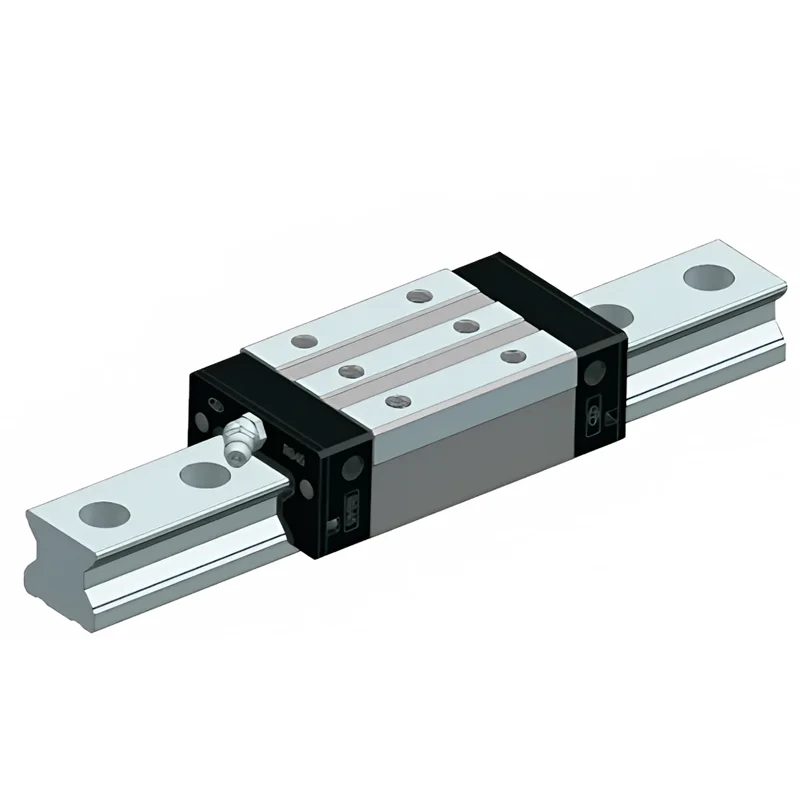

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd