How to avoid roller bearing failures

Understanding Premature Roller Bearing Failure and How to Prevent It

Roller bearings are critical mechanical components widely used in industrial equipment, automotive systems, and heavy machinery.

Their reliability directly affects operational efficiency, safety, and maintenance costs.

Premature roller bearing failure can lead to unexpected downtime, costly repairs, and reduced equipment lifespan.

Understanding the root causes of bearing failure is the first step toward selecting reliable products and implementing effective preventive measures.

Common Causes of Premature Roller Bearing Failure

Inadequate Lubrication

Inadequate lubrication is one of the most common causes of roller bearing failure.

Insufficient lubricant or the use of an incorrect lubricant type increases friction between rolling elements and raceways.

This excessive friction generates heat, accelerates wear, and eventually leads to surface damage or seizure.

Following recommended lubrication intervals and using application-specific lubricants is essential for stable bearing performance.

Contamination by Foreign Particles

Contaminants such as dust, dirt, metal particles, or moisture can easily enter the bearing system.

Once inside, these contaminants damage rolling surfaces and degrade lubricant effectiveness.

Over time, contamination causes abrasion, corrosion, and premature fatigue.

Proper sealing solutions and clean operating environments are crucial to maintaining bearing integrity.

Improper Installation and Handling

Improper installation is a major contributor to early bearing failure.

Excessive force, incorrect mounting methods, or misalignment during installation can damage bearing components.

Transportation and storage mishandling may also introduce invisible internal stress.

Using correct tools and following standardized installation procedures helps ensure optimal bearing alignment and performance.

Excessive Load and Misalignment

Bearings are designed to operate within specific load and speed limits.

Excessive radial or axial loads beyond design capacity significantly shorten bearing service life.

Misalignment between shafts and housings further increases localized stress.

Accurate load calculation and proper bearing selection are vital for avoiding overloading conditions.

Fatigue and Harsh Operating Conditions

Fatigue failure occurs due to repeated stress cycles over time.

High operating speeds, elevated temperatures, and poor maintenance accelerate fatigue damage.

Operating bearings outside recommended limits reduces material endurance.

Routine inspection and condition monitoring help identify early signs of fatigue.

How to Avoid Premature Bearing Failure

Although bearing failure cannot be completely eliminated, it can be effectively delayed with proper planning and maintenance.

Implementing preventive strategies ensures consistent performance and reduces operational risks.

Select the Correct Bearing for the Application

Choosing the correct bearing type and size is the foundation of long service life.

The bearing must match load requirements, operating speed, and environmental conditions.

High-quality roller bearings manufactured to strict tolerances offer improved reliability in demanding applications.

Ensure Proper Installation Practices

Bearings should always be installed using approved tools and controlled methods.

Force should never be applied directly to rolling elements.

After installation, alignment and seating must be verified.

Correct installation minimizes internal stress and ensures smooth rotation.

Follow Manufacturer Lubrication Guidelines

Lubrication plays a critical role throughout the bearing’s service life.

The correct lubricant type, quantity, and relubrication interval must be strictly followed.

Over-lubrication and under-lubrication are equally harmful.

Consistent lubrication practices reduce friction, control temperature, and prevent corrosion.

Implement Preventive Maintenance and Monitoring

Regular inspections help detect abnormal noise, vibration, or temperature changes.

Early identification of these warning signs prevents catastrophic failure.

Condition monitoring systems improve maintenance efficiency and equipment reliability.

Why Choose Reliable Bearing Solutions

High-performance roller bearings play a key role in maintaining stable operations.

Products supplied by SAIVS are engineered to meet strict quality standards and demanding industrial requirements.

By combining proper bearing selection, correct installation, and professional technical support, users can significantly extend bearing service life.

Reliable bearing solutions help reduce downtime, lower maintenance costs, and improve overall equipment performance.

Conclusion

Premature roller bearing failure is often caused by preventable factors.

Addressing lubrication, contamination, installation, and load conditions is essential.

Choosing high-quality bearings and following best practices ensures long-term reliability.

This approach creates lasting value for industrial operations and procurement decisions.

How to avoid roller bearing failures

How to avoid roller bearing failures

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

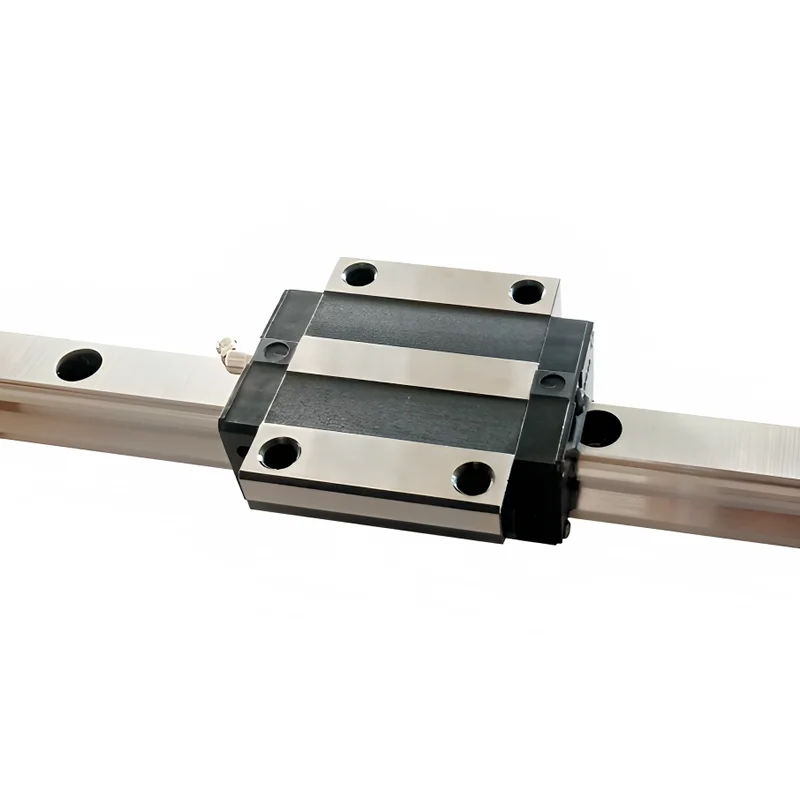

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

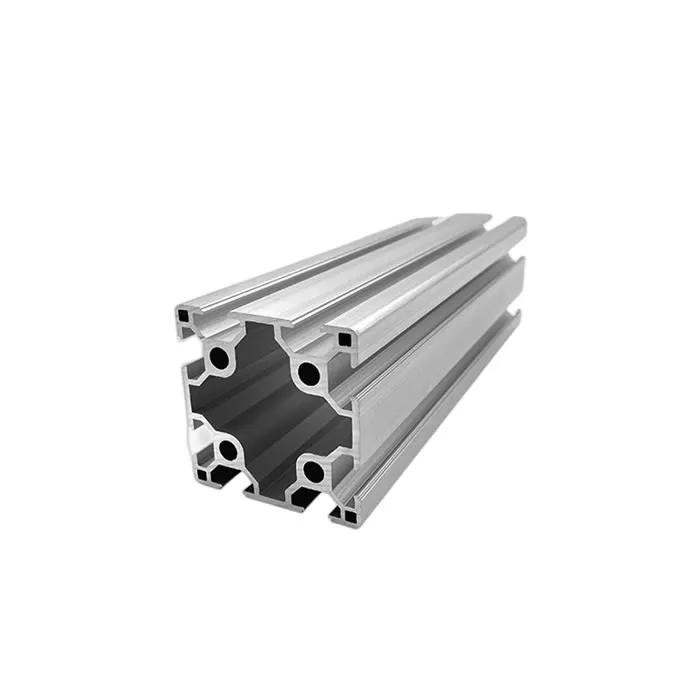

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd