How to choose hex cap screws

Selecting the appropriate hex cap screws for your project ensures a strong, secure, and functional assembly. Here's a breakdown of key factors to consider:

Size and Length

Match screw dimensions to your project: Determine the screw's diameter and length based on the materials you're fastening. Consider the thickness of each material and any spacers or components the screw needs to pass through.

Choose the right length for grip: The screw should thread into the bottom material with enough length to provide a firm grip. Avoid excessively long screws that waste material.

Thread Size

Diameter and Threads per Inch (TPI): Hex cap screws come in various thread sizes. The diameter is typically denoted in inches (e.g., ¼", ⅜") and threads per inch (TPI).

Compatibility is key: Ensure the screw's thread size matches the nut or pre-threaded hole you're using for a secure fit.

Material

Material selection for your environment: Consider the environmental conditions and stress placed on the screws. Common options include:

Stainless Steel: Excellent corrosion resistance but might not be the strongest.

Carbon Steel: Strong and affordable, but susceptible to rust.

Alloy Steel: Offers a balance between strength and corrosion resistance.

Strength Grade

Strength based on load: Hex cap screws come in various strength grades (e.g., Grade 2, 5, 8), with higher grades offering greater strength. Choose a grade that can handle the load your application will experience.

Head Style

Hexagonal head for easy tightening: Hex cap screws have a six-sided (hexagonal) head that allows for easy tightening with a wrench or socket driver.

Finish

Aesthetics and functionality: Consider any desired finish for your screws. Options include:

Plain: Most basic finish, suitable for general applications.

Plated: Provides corrosion resistance or a decorative look.

Coated: Enhances weather resistance or lubricity.

By considering these factors, you can choose the optimal hex cap screws for your project, ensuring a secure and successful outcome.

How to avoid roller bearing failures

How to avoid roller bearing failures

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

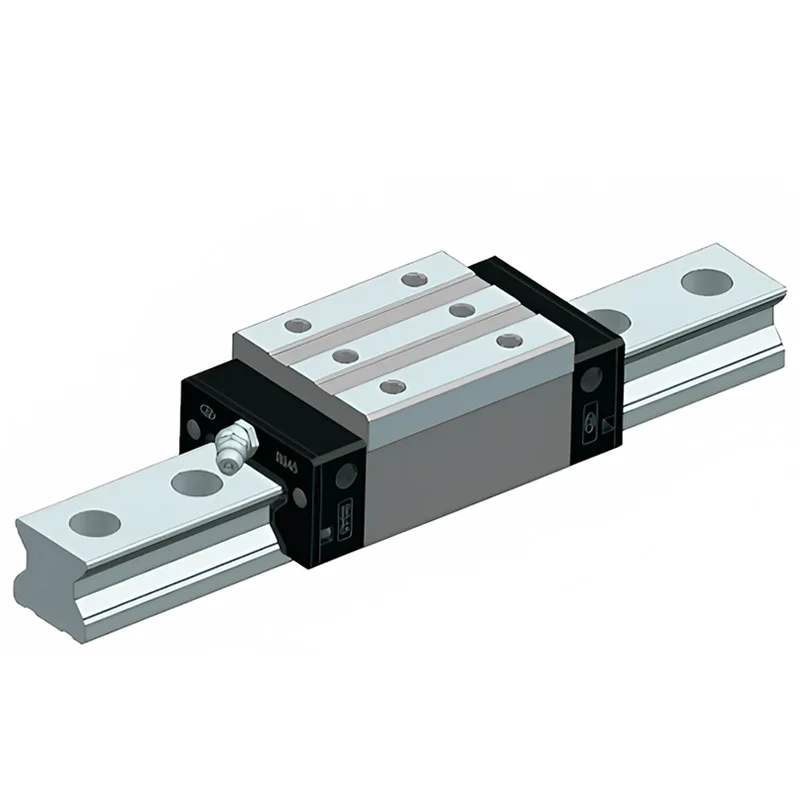

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd