Understanding wheel types

Because casters are designed to make things move, the most critical part of a caster is the wheel.

It is important to know the different types of wheel materials and the benefits of each type.

Soft Tread Wheels

Soft tread wheels are an excellent choice when you need a caster that provides a cushioned ride and

protects delicate flooring surfaces. These wheels are typically made of thermoplastic or mold-on rubber,

offering high resistance to chemicals, oils, and acids. The soft tread allows the wheels to roll smoothly

over small debris and also reduces noise compared to other materials. However, it's important to note

that soft tread wheels may be slightly more difficult to roll and have a lower load capacity.

There are several common types of soft tread caster wheels available:

1. Thermoplastic Rubber: These wheels combine the durability of thermoplastics

with the flexibility and grip of rubber. They offer good chemical resistance and can handle light to medium loads.

2. Rubber Tread on Iron Core: With a rubber outer layer bonded onto an iron core, these wheels provide

enhanced durability and load capacity while still offering floor protection.

3. Polyurethane Tread on Plastic Core: Polyurethane tread wheels provide easier rollability compared to soft

treads while maintaining excellent floor protection. They can support heavier loads,

with capacities reaching up to 3,000 pounds.

Polyurethane Tread Wheels

Polyurethane tread wheels offer improved rollability compared to soft tread options while still providing

excellent floor protection. These wheels come in different configurations:

1. Solid Urethane: Solid urethane wheels eliminate the risk of tread separation or core corrosion because

they are entirely made of molded urethane without any core material. They are ideal for

wash-down applications and provide reliable performance under heavy loads.

2. Chemically or Mechanically Bonded: Polyurethane treads chemically or mechanically bonded onto plastic

cores or cast iron/aluminum cores offer a balance between rollability and load capacity.

While polyurethane is known for its impact resistance, it's important to note that the polyurethane

tread can separate from the core if overloaded or damaged in some way.

However, this risk is mitigated by using solid urethane wheels.

Synthetic Tread Wheels

Synthetic tread wheels feature harder treads that offer low rolling resistance along with

high impact strength and reliability. Different types of synthetic wheel materials include:

1.Synthetic Elastomer: Solid elastomer tires provide excellent impact resistance suitable for abusive environments.

2.Polypropylene/Polyolefin: These lightweight synthetic wheel

options deliver good load-carrying capacity along with chemical resistance.

3.Fiberglass Reinforced Polypropylene: This type offers enhanced strength due to fiberglass reinforcement.

4.Phenolic: Phenolic resin-based synthetic treads provide high-temperature tolerance but may not be suitable for wet environments.

5.Solid Nylon: Solid nylon tires exhibit exceptional strength but tend to be louder when rolling over debris than softer materials.

When selecting synthetic tread materials for your application, it is crucial to consider factors

such as impact resistance requirements,durability,and environmental compatibility

since some synthetics may not be suitable for wet conditions.

Ferrous Wheels

Ferrous (metallic)wheels are renowned for their solid structure,strong load capacity,resistance against impacts,

and wide temperature range suitability.Most commonly available ferrous wheel options include forged steel,

wheels cast from iron.These robust options excel in demanding industrial environments like warehouses

manufacturing plants where protecting flooring surfaces isn't necessarily a primary concern.Instead,

focus lies primarily on supporting heavy loads,durability,and reliability.

How to avoid roller bearing failures

How to avoid roller bearing failures

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

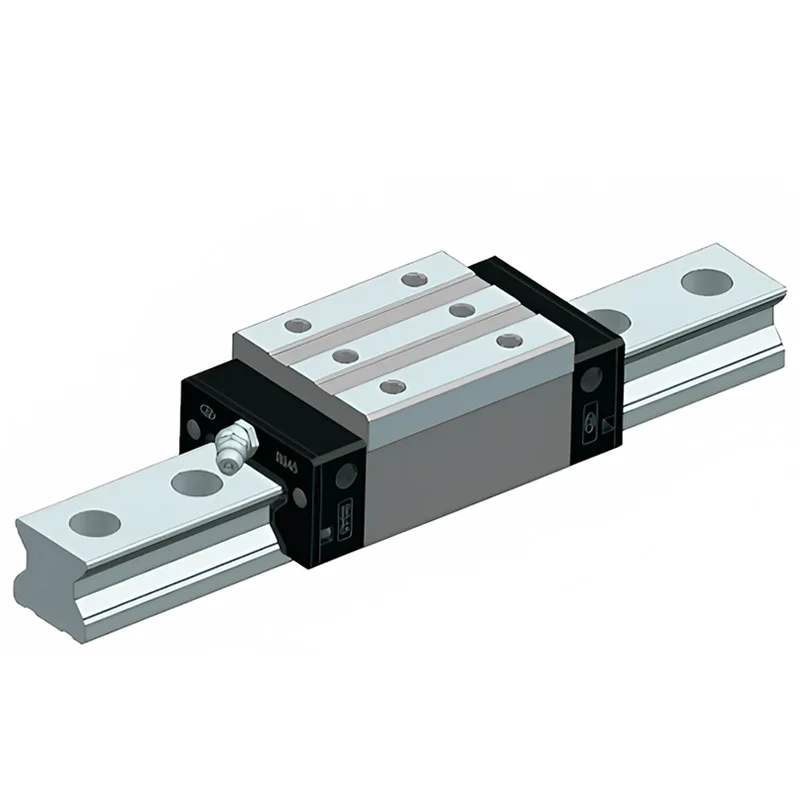

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd