Models HSR-R/RM/XR THK Linear Guides

Features

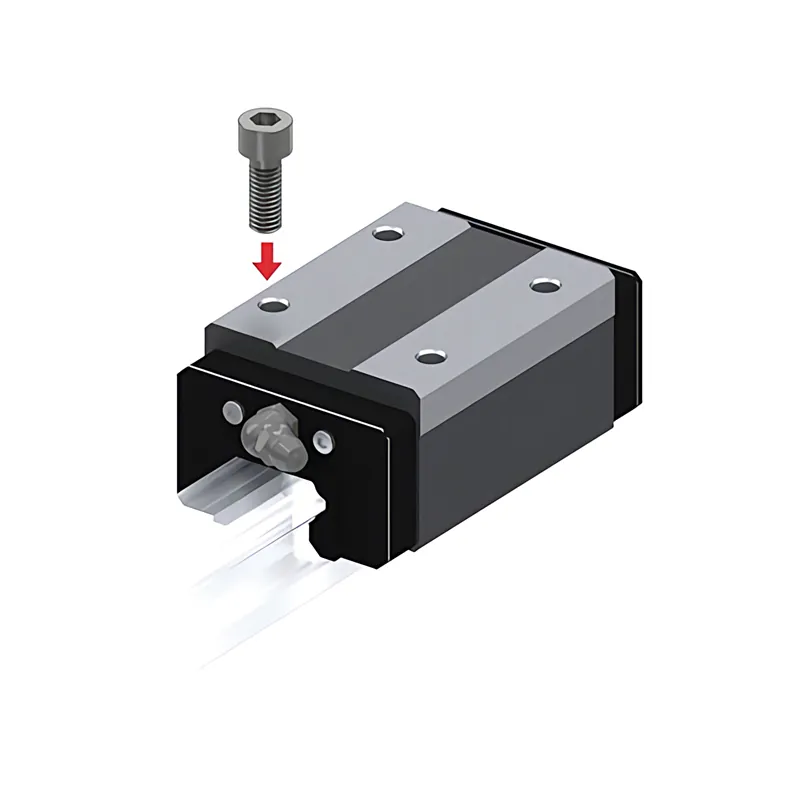

Four-row Raceways: Precision-ground raceways on both the LM rail and LM block allow for smooth rolling of balls, facilitating precise motion.

Retainer Plates: These hold the balls in place, ensuring they don't fall off even if the LM rail is pulled out. However, there may be exceptions for certain models.

Contact Angle: Each row of balls is placed at a contact angle of 45 degrees, ensuring uniform rated loads in all directions (radial, reverse radial, and lateral), enabling versatile usage in various orientations.

High Rigidity Type: The arrangement of balls in four rows allows for a large preload and easy increase in rigidity in all directions.

Self-adjustment Capability: The system can absorb mounting errors, even under preload, through THK's unique circular-arc grooves, enabling highly accurate and smooth motion.

4-Way Equal Load: This ensures that rated loads applied to the LM block are uniform in all directions, making the guide suitable for extensive applications.

Stainless Steel Type: There's an option for a special type where the LM block, LM rail, and balls are made of stainless steel, which provides additional durability and resistance to corrosion.

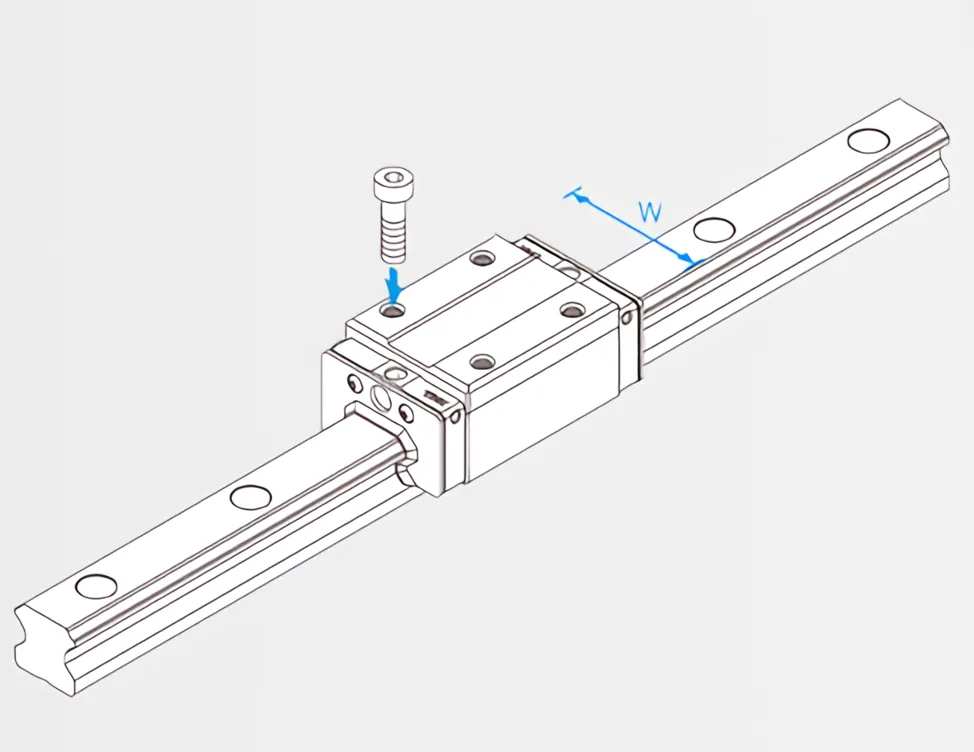

| Model No | Outer dimensions | Basic load ratino | |||

| Radial | |||||

| Height M | Width W | Length L | Dynamic rating C | Static rating Co | |

| mm | mm | mm | kN | kN | |

| HSR 8RM | 11 | 16 | 24 | 1.08 | 2.16 |

| HSR 10RM | 13 | 20 | 31 | 1.96 | 3.82 |

| HSR 12RM | 20 | 27 | 45 | 4.7 | 8.53 |

| HSR 15R | 28 | 34 | 56.6 | 10.9 | 15.7 |

| HSR 15RM | 28 | 34 | 56.6 | 10.9 | 15.7 |

| HSR 20R | 30 | 44 | 74 | 19.8 | 27.4 |

| HSR 20RM | 30 | 44 | 74 | 19.8 | 27.4 |

| HSR 25R | 40 | 48 | 83.1 | 27.6 | 36.4 |

| HSR 25RM | 40 | 48 | 83.1 | 27.6 | 36.4 |

| HSR 30R | 45 | 60 | 98 | 40.5 | 53.7 |

| HSR 30RM | 45 | 60 | 98 | 40.5 | 53.7 |

| HSR 35R | 55 | 70 | 109.4 | 53.9 | 70.2 |

| HSR 35RM | 55 | 70 | 1094 | 53.9 | 70.2 |

| HSR 45R | 70 | 86 | 139 | 82.2 | 101 |

| HSR 55R | 80 | 100 | 163 | 121 | 146 |

| HSR 65XR | 90 | 126 | 190.5 | 195 | 228 |

| HSR 85R | 110 | 156 | 245.6 | 304 | 355 |

Advantages of Linear Guides

(1)High pasitional accuracy

(2)Long life with high moction accuracy

(3)High speed motion is possible with a low driving force

(4)Easy installation

(5)Equal loading capacity in all directions

(6)Easy lubrication

Product Feature of Linear Support Rail Unit

1.Interchangeable

2.Max length: 6000mm

3.High quality standard

4.Rail: Length can be cut freely

Features of Linear Slide Unit

1. Widely used in electronic equipment, food machinery, tools, machinery, CNC machine tools,Automotive and digital three-dimensional equipment or special machinery industry;

2. Used with the quenching linear drive shaft, Small friction resistance and high precision;

3. Guide rails can be used for docking, Small friction resistance and high precision.

| Support Designation | Shaft Dimensions | Dimensions (mm) | S2(d1*d2*i) | Weight (g/m) | |||||||||

| E | h | B | H | T | F | X | Y | C | SI | ||||

| SBR12 | Φ12 | 15 | 22.5 | 32 | 16.5 | 4 | 12 | 6 | 12 | 22 | Φ4.5 | 4.5X8X4.5 | 1.4 |

| SBR16 | Φ16 | 20 | 25 | 40 | 17.8 | 5 | 18.5 | 8 | 11.7 | 30 | Φ5.5 | 5.5X9.5X5.4 | 2.56 |

| SBR20 | Φ20 | 22.5 | 27 | 45 | 17.7 | 5 | 19 | 8 | 10 | 30 | Φ5.5 | 5.5X9.5X5.4 | 3.5 |

| SBR25 | Φ25 | 27.5 | 33 | 55 | 21 | 6 | 21.5 | 8 | 12 | 35 | Φ6.6 | 6.6X 11X6.5 | 5.3 |

| SBR30 | Φ30 | 30 | 37 | 60 | 22.8 | 7 | 26.5 | 10.3 | 13 | 40 | Φ6.6 | 6.6X11X6.5 | 7.38 |

| SBR35 | Φ35 | 32.5 | 43 | 65 | 26.5 | 8 | 28 | 13 | 15.5 | 45 | Φ9 | 9X14X8.6 | 9.68 |

| SBR40 | Φ40 | 37.5 | 48 | 75 | 29.5 | 9 | 38 | 15.5 | 17 | 55 | Φ9 | 9X14X8.6 | 12.69 |

| SBR50 | Φ50 | 47.5 | 62 | 95 | 38.8 | 11 | 45 | 20 | 21 | 70 | Φ11 | 11X17.5X10.8 | 20.46 |

| Designation | SBR 16 | SBR 20 | SBR 25 | SBR 30 | SBR 35 | SBR 40 | SBR 50 |

| Standard Length L | 190 | 340 | 250 | 450 | 460 | 460 | 470 |

| 340 | 640 | 450 | 850 | 660 | 660 | 670 | |

| 640 | 940 | 850 | 1250 | 860 | 1060 | 1070 | |

| 940 | 1240 | 1250 | 1450 | 1060 | 1260 | 1270 | |

| N | 20 | 20 | 25 | 25 | 30 | 30 | 35 |

| P | 150 | 150 | 200 | 200 | 200 | 200 | 200 |

| Max.length | 6000 | 6000 | 6000 | 1850 | 6000 | 6000 | 6000 |