SAIVS:meet your needs for bearings

Why Should You Choose SAIVS Bearing for Your Bearing Needs?

There are several benefits of working with SAIVS Bearing. Working with an experienced

bearing provider with a large inventory expands your options.

Some of the bearing options that we can source for you include:

We source bearings for a diverse range of industries, including:

Automotive industry

Oil and gas industry

Printing industry

Railway industry

Medical equipment

Material handling

Renewable energy

Tips to Protect and Maintain Your Bearings

1. Proper lubrication: Ensure that your bearings are adequately lubricated

with the appropriate type and amount of lubricant. Lubrication helps reduce friction and wear,

extending the lifespan of the bearings. Follow manufacturer guidelines for lubrication

intervals and use high-quality lubricants suitable for the specific application.

2. Regular cleaning: Keep your bearings clean by removing dirt, debris, and contaminants that

can cause damage or hinder performance. Use a soft cloth or brush to gently clean the

bearing surfaces, taking care not to scratch or damage them.

3. Correct installation: Ensure proper installation of bearings by following manufacturer

instructions or consulting with a professional if needed. Improper installation can lead

to premature failure or reduced performance. Pay attention to factors such

as mounting techniques, torque specifications, and alignment.

4. Protection from moisture and corrosion: Protect your bearings from moisture,

water ingress, and corrosive environments as these can significantly impact their

performance and lifespan. Consider using seals or shields to prevent

contaminants from entering the bearing housing.

5. Regular inspection: Perform regular visual inspections of your bearings for

signs of wear, damage, or abnormal operating conditions such as overheating or noise.

Catching potential issues early can help prevent major failures and minimize downtime.

Remember that specific maintenance requirements may vary depending on the type of

bearing used (e.g., ball bearings vs roller bearings) as well as the application

they are used in (e.g., industrial machinery vs automotive). It's always best to consult

with manufacturers' guidelines for specific recommendations tailored to your equipment's needs.

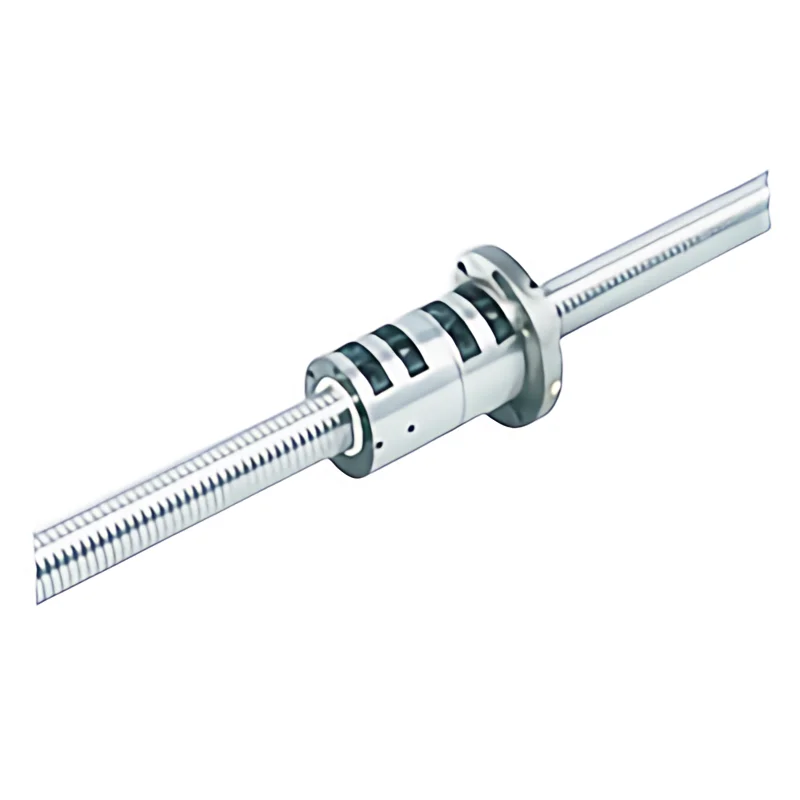

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

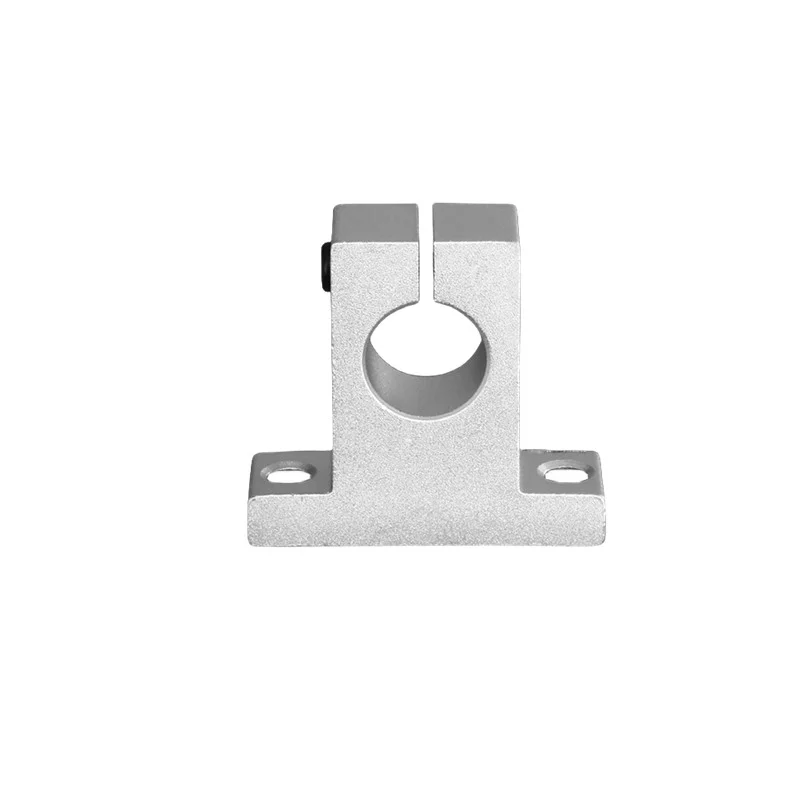

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

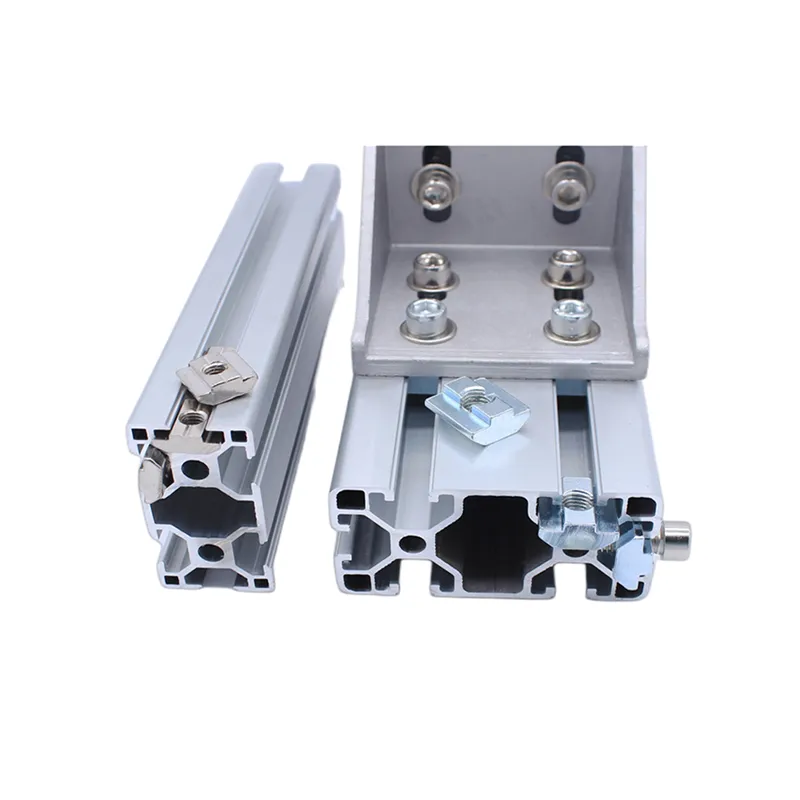

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS