Why Ball Screws are Generally More Expensive Than Lead Screws

Ball Screws are typically more expensive than lead screws due to a combination of factors related to their design, manufacturing complexity, and performance characteristics:

1. Manufacturing Complexity:

Precision engineering: Ball screws require precise manufacturing to ensure smooth operation and long life. This involves advanced machining processes and stringent quality control.

Ball recirculation: The intricate ball recirculation system adds complexity to the manufacturing process, increasing costs.

2. Material and Quality:

High-grade steel: Ball screws are made from high-quality steel alloys to withstand heavy loads and prevent wear. These materials are more expensive than those used in other screw mechanisms.

Surface treatment: To enhance performance and durability, ball screws often undergo specialized surface treatments like hardening and grinding, adding to the cost.

3. Efficiency and Performance:

Higher efficiency: Ball screws offer superior efficiency compared to other screw mechanisms, translating to lower energy consumption and higher load capacity. However, this advanced performance comes at a premium.

Longer lifespan: Due to their precision and material quality, ball screws have a longer lifespan, reducing maintenance costs over time. While this is a long-term benefit, the initial investment is higher.

4. Research and Development:

Continuous improvement: Ball screw manufacturers invest heavily in research and development to enhance product performance and efficiency. These costs are reflected in the final product price.

While the initial cost of a ball screw may be higher, the long-term benefits in terms of efficiency, precision, and lifespan often outweigh the upfront investment for many applications.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

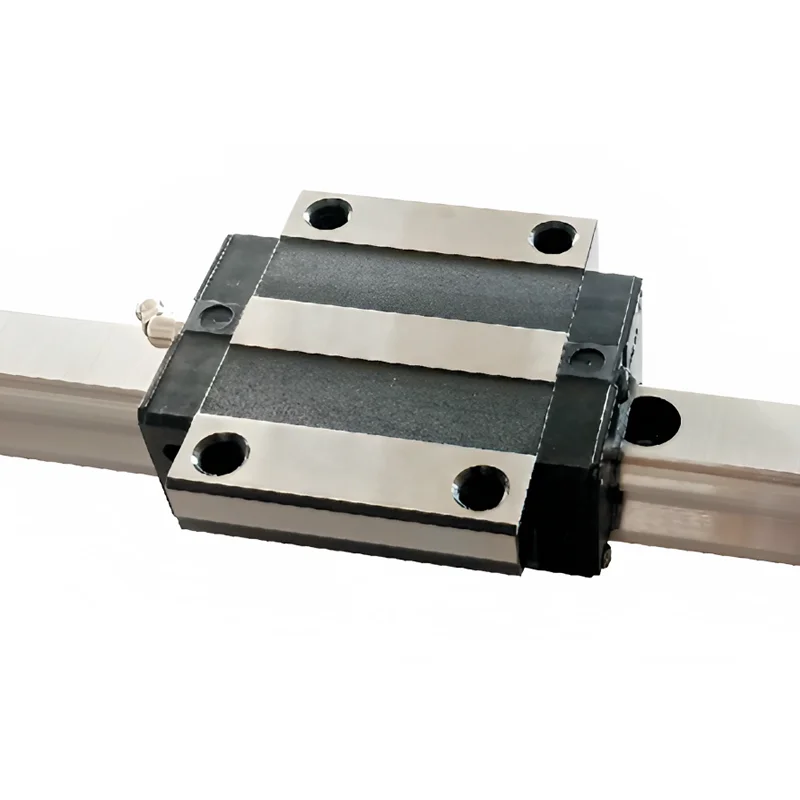

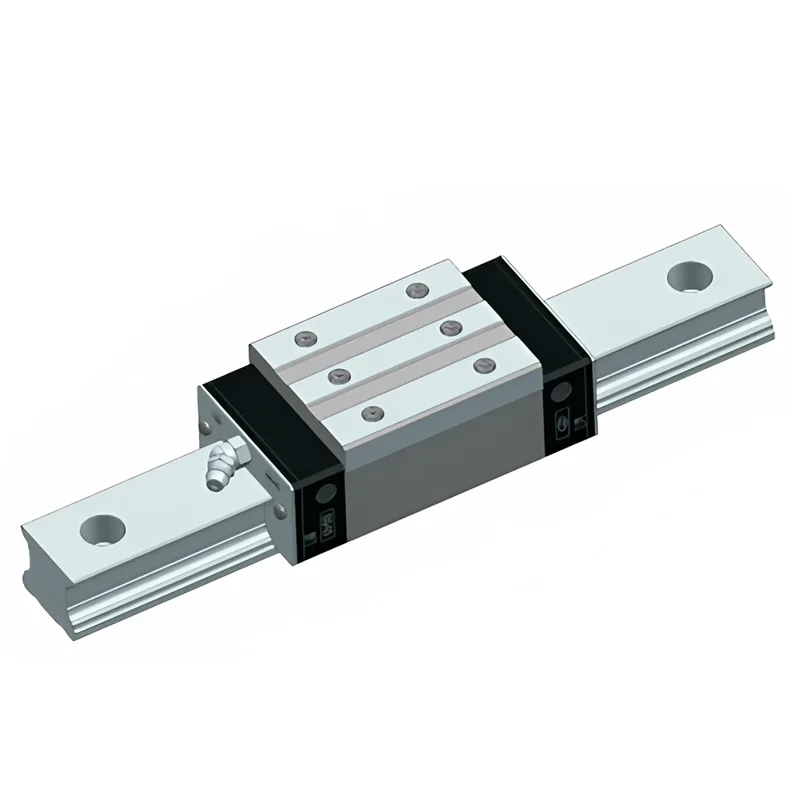

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

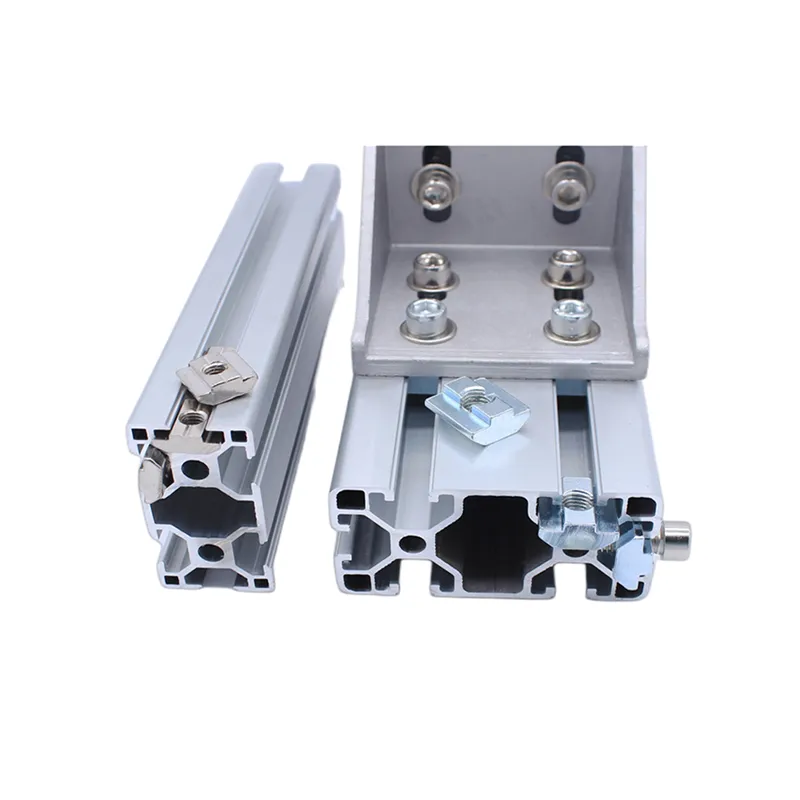

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS