Choosing the Right Bearing: Rod End vs. Thrust Bearings

How to Distinguish Between Rod End Bearings and Thrust Bearings

Bearings are designed with function in mind, not just aesthetics. This means you should be able to identify different types of bearings based on their appearance, particularly when dealing with distinct types like rod end bearings and thrust bearings.

Identifying Rod End Bearings

Rod end bearings feature a spherical inner ring and are equipped with a cylindrical hole for easy and convenient shaft installation. These mechanical joints essentially consist of a spherical swivel with an opening through which bolts or other attachments can be securely fastened. As a result, you can find rod end bearings in a wide range of machinery, from automotive steering columns to helicopter rotor assemblies.

It's important to note that depending on your location, you might encounter different names for rod end bearings. For example, in the UK, they are often called “rose joints,” while in the US, they are typically referred to as “heim joints.”

Identifying Thrust Bearings

Thrust bearings, on the other hand, look more like standard bearings. They are circular bearings with a pair of raised thrust rings that rotate around a shaft. There are numerous variations of thrust bearings, with ball and roller bearing options being just the tip of the iceberg.

When Do Rod End Bearings Excel?

So, what makes rod end bearings advantageous? If your application requires a precise articulated joint, rod end bearings are your best bet. Additionally, if for some reason you cannot use a clevis end in a particular position, rod end bearings are a great alternative.

This is because rod end bearings can rotate precisely in a controlled manner. They can accommodate low to moderate shaft misalignment—at any angle other than 90 degrees.

What Makes Thrust Bearings a Strong Contender?

If you are dealing with axial loads or forces (i.e., forces or loads aligned with the direction of the shaft), thrust bearings are a better option. They allow parts to rotate while supporting axial thrust in both horizontal and vertical axes. This is because the thrust rings transfer axial loads from the shaft to the bearing. Moreover, thrust bearings come in various designs, allowing you to select the specific type that best suits your application. This includes options for mounting them in a way that best fits your project’s needs.

So, if you are looking for exceptional performance with high load capacity—even in harsh environments—thrust bearings are a reliable choice.

Which One Should You Use?

When choosing between rod end bearings and thrust bearings, it ultimately comes down to whether you need to manage articulation or axial loads and forces. For the former, rod end bearings are always the better choice, while for the latter, thrust bearings are the way to go. Once you’ve answered this question, you can delve deeper into the specific types of bearings available within these categories. This might include considerations such as the materials they’re made from or specific design variations to better suit different applications.

By clearly understanding your project requirements, you’ll be able to make the most appropriate choice between rod end bearings and thrust bearings, ensuring optimal performance of your equipment.

How to avoid roller bearing failures

How to avoid roller bearing failures

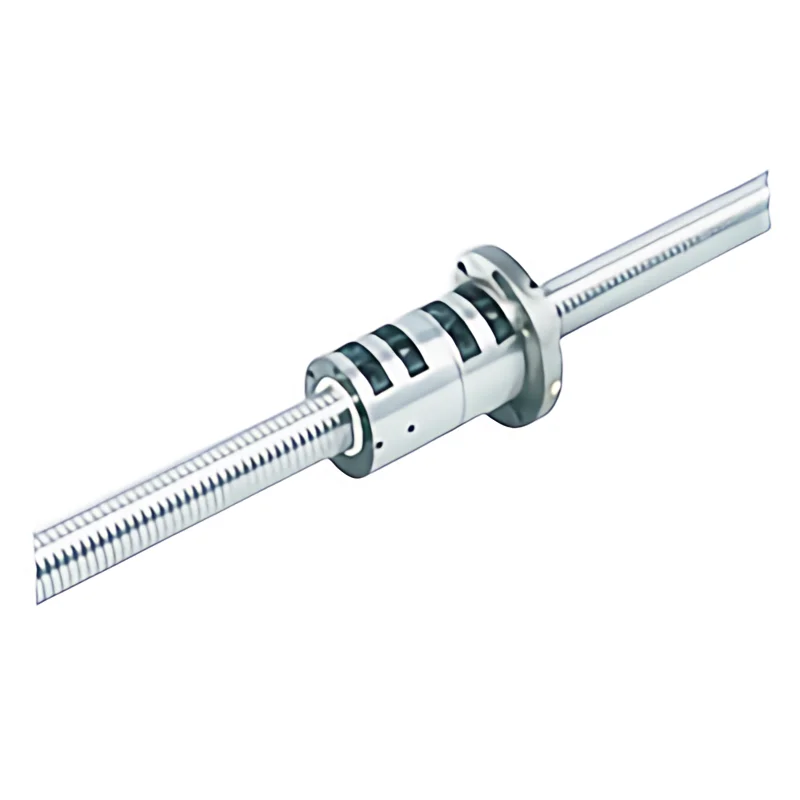

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd