What is the importance of aluminum connectors

The importance of Aluminum Profile Connectors lies in their ability

to provide strong and reliable connections in the assembly of aluminum structures.

Here are some key reasons why connectors are necessary:

1. Versatility

Connectors allow for flexible and modular design,

enabling easy customization and modification

of aluminum structures to meet specific needs.

2. Strength and Stability

Connectors ensure secure connections

between aluminum profiles, enhancing the overall

stability and load-bearing capacity of the structure.

3. Time and Cost Efficiency

Using connectors simplifies the assembly process,

reducing the need for complex welding or fabrication.

This results in saved time and lower labor costs.

4. Reusability

Connectors can be disassembled and reused,

making them a cost-effective solution for temporary structures,

prototype development, or reconfigurable setups.

5. Flexibility in Design Changes

Connectors allow for easyadjustments or additions to

the structure without the need for significant modifications or rebuilding.

6. Aesthetics

Connectors often have sleek and integrated designs,

providing a visually appealing finish to the aluminum structure.

Overall, Aluminum profile connectors play a vital role in ensuring

structural integrity, flexibility,

and efficiency in the assembly of aluminum structures.

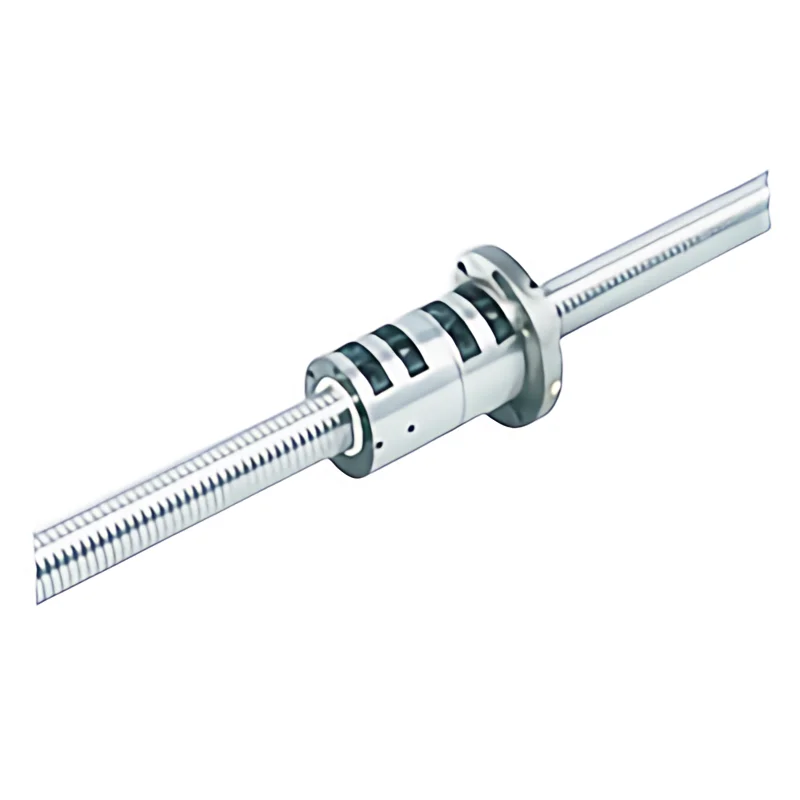

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS