How can you maintain and clean Aluminum profile connectors

SAIVS

Sep 06,2023

Regular cleaning: Wipe the connectors with a soft cloth

or brush to remove dust, dirt, or other contaminants.

Avoid abrasive cleaners: Do not use harsh or abrasive

cleaners that may damage the surface or finish of the connectors.

Corrosion prevention: In corrosive environments,

apply appropriate protective coatings or sealants

to the connectors to prevent oxidation and corrosion.

Lubrication: If necessary, apply a small amount

of lubricant to moving parts or joints to

ensure smooth operation and prevent wear.

Regular maintenance and cleaning

help preserve the appearance, functionality,

and longevity of Aluminum Profile Connectors.

Recommend Posts

Read More >>

How to avoid roller bearing failures

How to avoid roller bearing failures

Jan 21,2026

Premature roller bearing failure can occur due to various factors, including inadequate lubrication,...

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Apr 25,2025

In the fast-evolving world of industrial automation, precision and efficiency ar

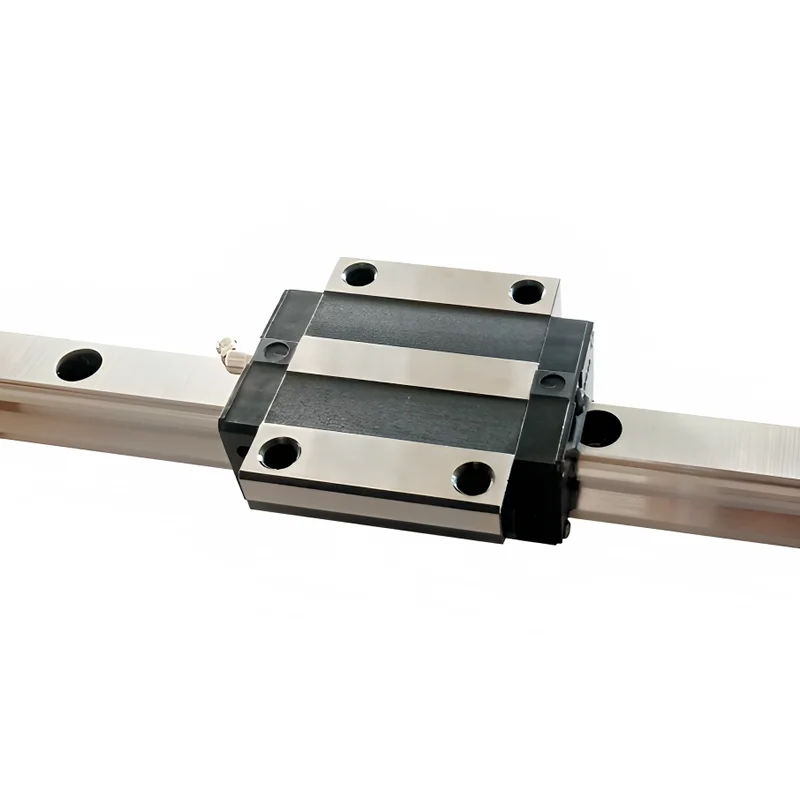

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

Apr 03,2025

Enhance Your CNC Precision with SAIVS Linear Motion Ball Slide UnitsIn the rapidly advancing world o...

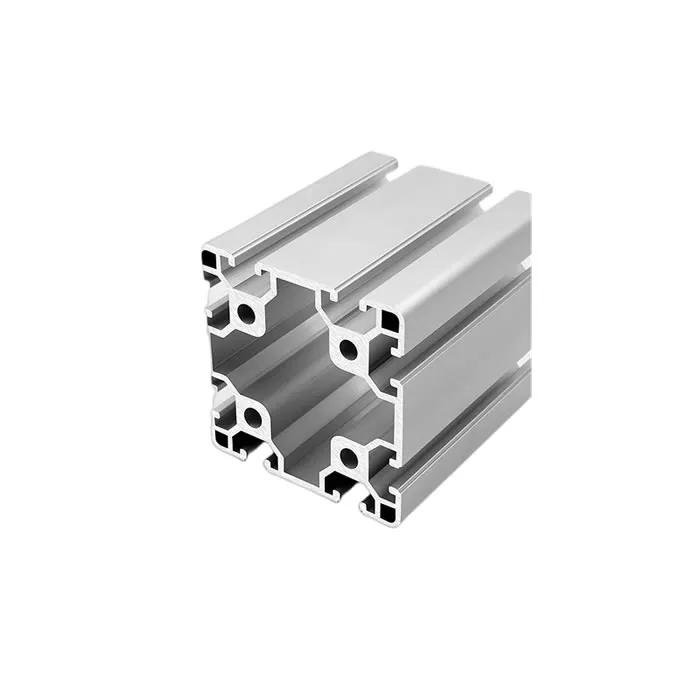

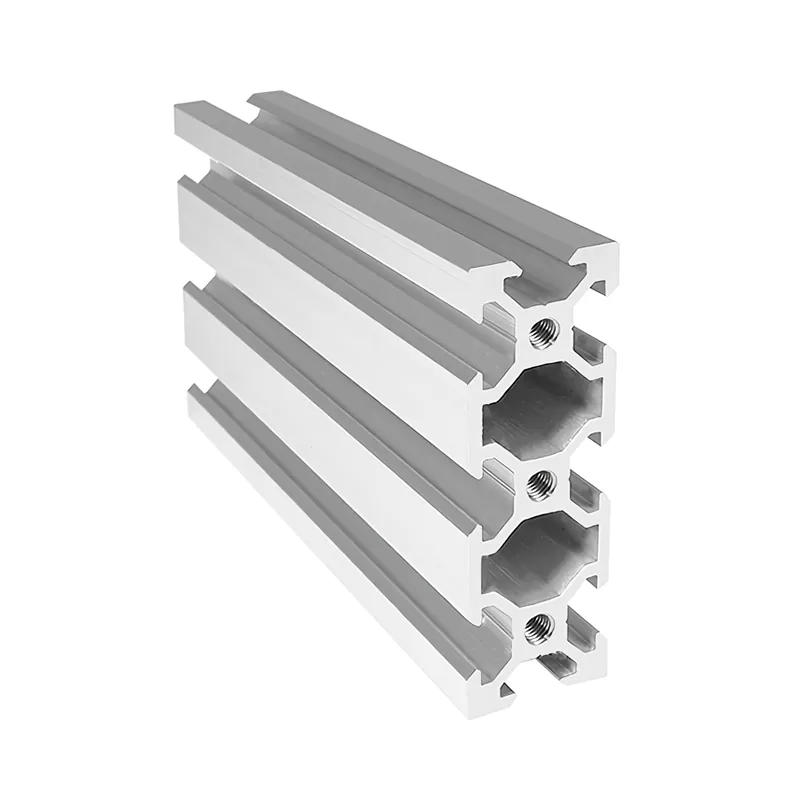

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Mar 20,2025

T - Slot Aluminum Extrusion Profile: The Ideal Choice for Your ProjectsIn the world of industrial ...