Advantages of Ball Screw

Ball Screws are mechanical devices that are used to convert rotary motion into linear motion.

These devices have been around for many years, and have become quite popular in recent times due to their numerous advantages.

In this article, we will talk about the advantages of ball screws and why they are widely used in various industries.

High Efficiency

Ball screws have low friction due to the rolling contact between the ball bearings and the screw threads.

This results in higher mechanical efficiency compared to other screw mechanisms, such as lead screws.

The reduced friction also translates to less power consumption and heat generation.

High Precision

Ball screws are known for their exceptional precision and accuracy.

The rolling contact between the balls and the screw threads minimizes backlash and provides precise positioning,

making them suitable for applications that require tight tolerances and consistent motion control.

Reduced Backlash

Backlash is the play or clearance between mating components in a mechanical system.

Ball screws have minimal backlash due to the preload on the ball bearings.

This characteristic ensures accurate and repeatable motion, especially in applications where reversing direction is frequent.

High Load Capacity

Ball screws can handle high axial loads,

making them suitable for applications that require heavy lifting or high force transmission.

The ball bearings distribute the load evenly, reducing wear and extending the life of the system.

Long Service Life

With proper maintenance and lubrication,

ball screws have a long service life due to the reduced friction and wear associated with their design.

This is especially beneficial in industrial settings where downtime for maintenance is costly.

High Speed Capability

Ball screws can achieve high linear speeds without sacrificing accuracy.

The low friction and rolling contact enable rapid movement,

making them suitable for applications that require both speed and precision.

Compact Design

Ball screws offer a high power-to-size ratio,

allowing for a compact design that saves space in various applications.

This is particularly advantageous in industries where space constraints are a concern.

Low Maintenance

The reduced wear and friction of ball screws contribute to low maintenance requirements.

Regular lubrication and periodic inspections are typically sufficient to ensure optimal performance and longevity.

While ball screws offer numerous advantages, it's important to consider factors such as cost, maintenance,

and application-specific requirements when choosing the appropriate linear motion solution for a given project.

Conclusion

Ball screws are an essential component of various industrial applications due to their numerous advantages.

advantages make ball screws the preferred choice in industries such as manufacturing, aerospace, and automotive.

With the increased demand for high-quality and cost-effective solutions,

ball screws have become an indispensable part of various industrial applications.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

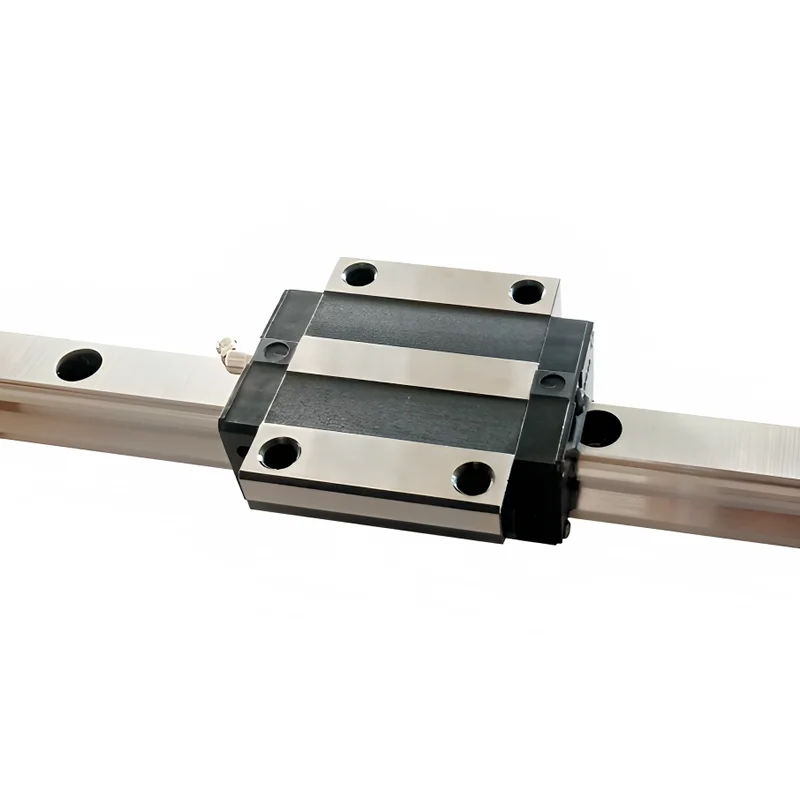

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS