Ball Screw Materials

In industrial automation and robotics, where precision and reliability are paramount, Ball Screws play a vital role. They efficiently convert rotary motion into highly accurate linear motion, driving peak performance in these demanding applications.

However, the selection of ball screw materials is critical. These materials directly impact the durability and overall performance of the system. Understanding the key components and their material considerations empowers engineers and manufacturers to make informed choices.

Core Components and Material Selection

Screw Shaft: This is the backbone of the ball screw, and its material selection is crucial for longevity. High-quality alloy steel, such as chromium-molybdenum steel, is often used due to its exceptional strength, hardness, and wear resistance. This ensures the shaft can handle significant loads and repetitive motion without succumbing to deformation or breakage.

Ball Nut: Responsible for translating rotational motion, the ball nut is commonly crafted from materials like brass or steel. These materials offer a good balance of strength and rigidity, allowing the nut to effectively engage with the screw threads and maintain precise positioning over time.

Balls: These tiny spheres play a critical role in minimizing friction. They are typically manufactured from high-grade bearing steel or ceramic materials known for their exceptional hardness, smooth surface finish, and outstanding wear resistance. The precise and consistent shape of the balls minimizes friction and backlash during operation, leading to superior efficiency and positional accuracy.

Material Selection for Optimal Performance

By carefully selecting materials for each component – screw shaft, ball nut, and balls – ball screws achieve the necessary properties to:

Withstand High Loads: The chosen materials ensure the ball screw can handle significant loads without compromising functionality.

Maintain Precision: The combination of materials minimizes friction and wear, allowing for precise and consistent linear motion.

Deliver Long-lasting Performance: Durable materials ensure the ball screw operates efficiently and reliably over an extended lifespan.

In conclusion, the selection of appropriate materials is fundamental to the performance and longevity of ball screws in various demanding applications. By understanding the critical role of each component's material properties, engineers and manufacturers can make informed choices that contribute to the success of their projects.

How to avoid roller bearing failures

How to avoid roller bearing failures

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

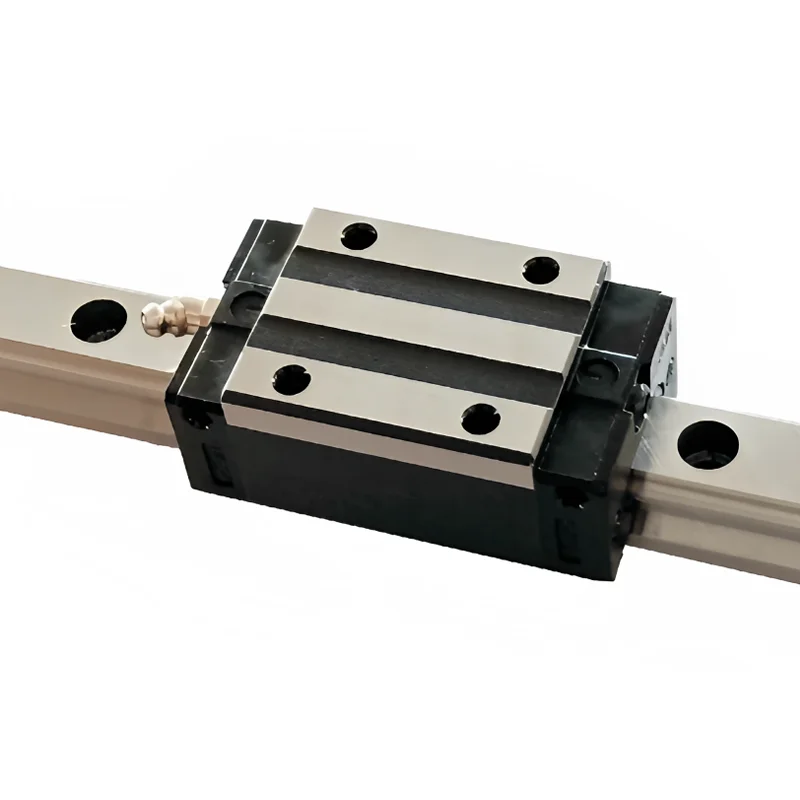

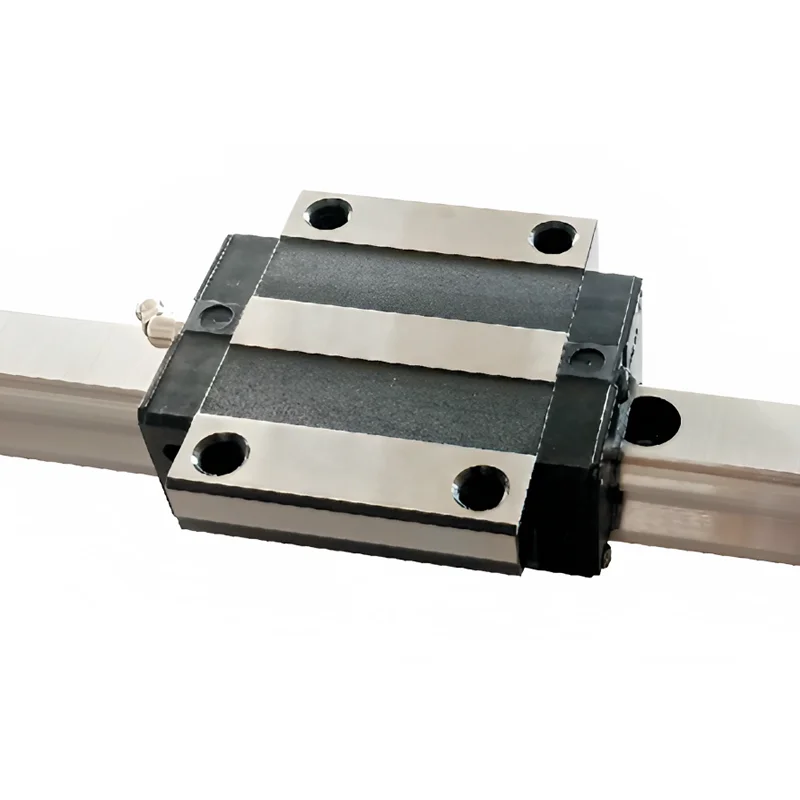

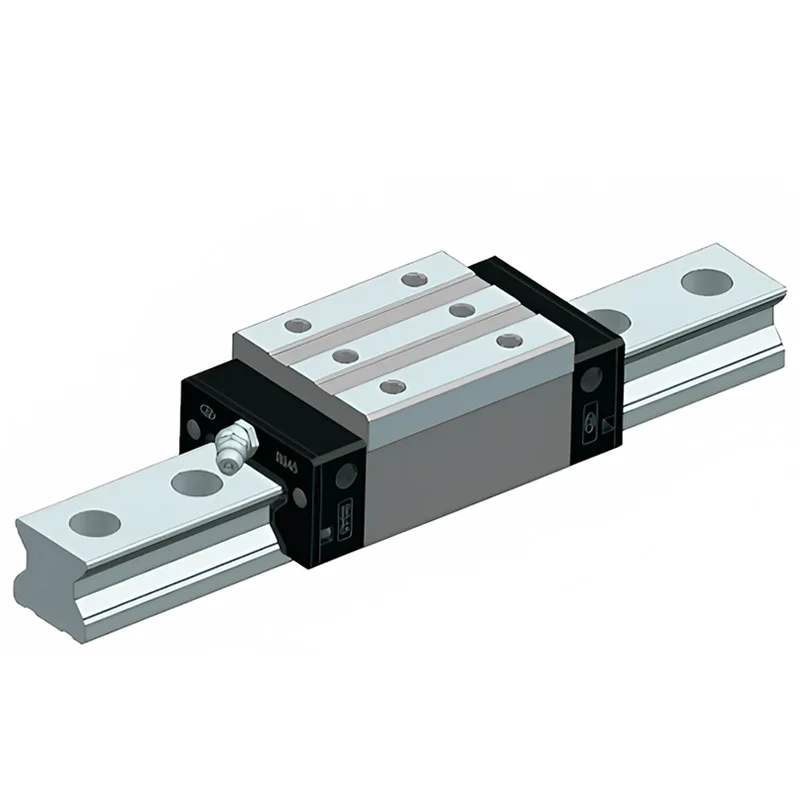

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

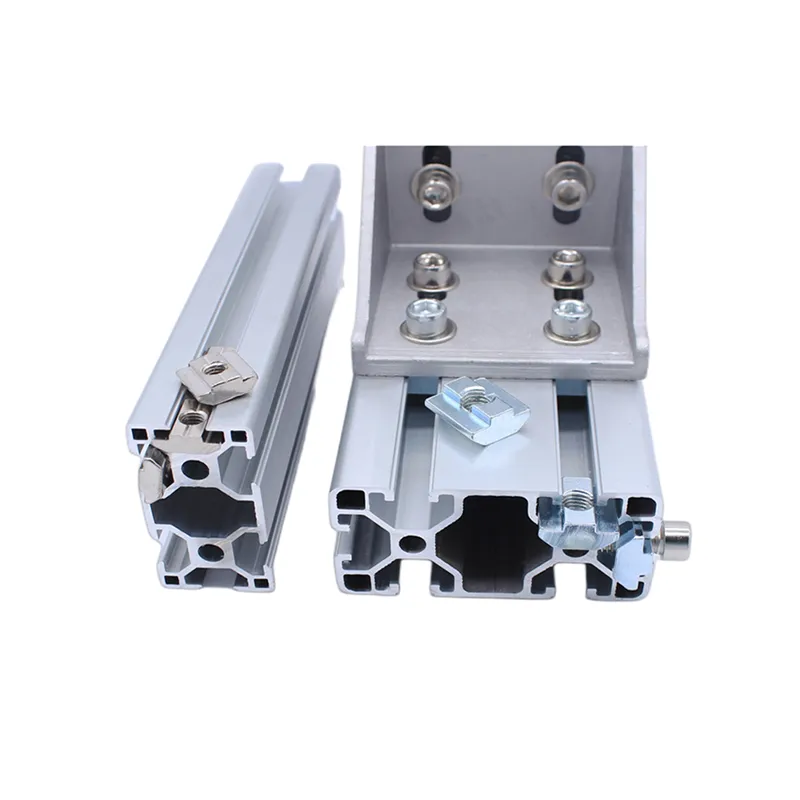

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd