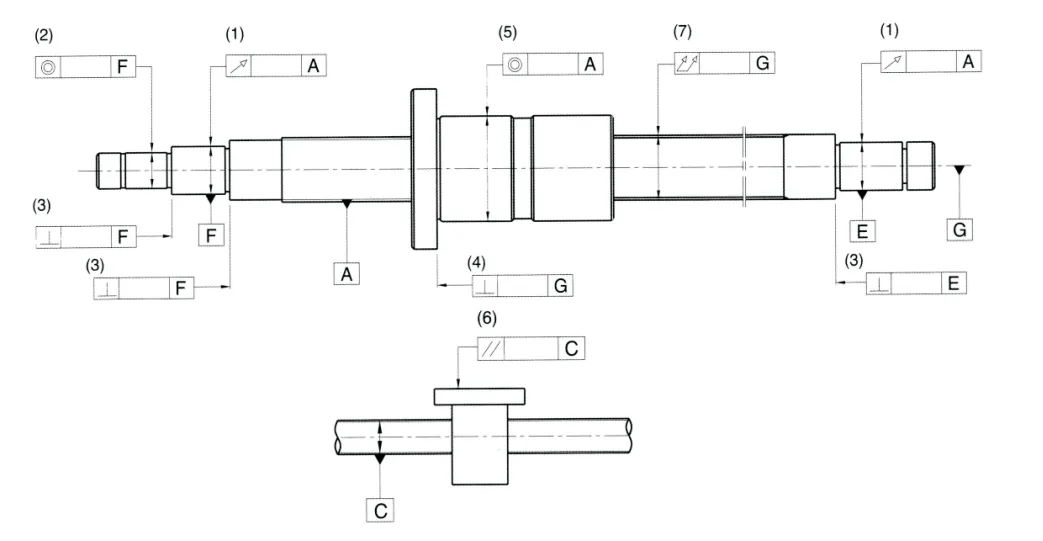

Accuracy of installation position of ball screw

The necessary items for the accuracy of the installation position of the Ball Screw are as follows:

(1) Measure the circumferential deviation value in the radial direction

of the support part of the screw rod relative to the axis A of the threaded groove surface.

(2) Measure the coaxiality of the installation position of the part relative to the axis F of the screw support position.

(3) Measure the squareness of the end face of the supporting part relative to the axis E of the screw shaft support part

(4) Measure the rightness of the reference surface of the nut or the mounting surface of the flange relative to the axis G of the screw.

(5) Measure the coaxiality of the outer circumference (cylindrical) of the nut relative to the screw axis A.

(6) The parallelism of the outer edge (flat head mounting surface) of the indefinite nut relative to the axis C of the screw rod.

How to avoid roller bearing failures

How to avoid roller bearing failures

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

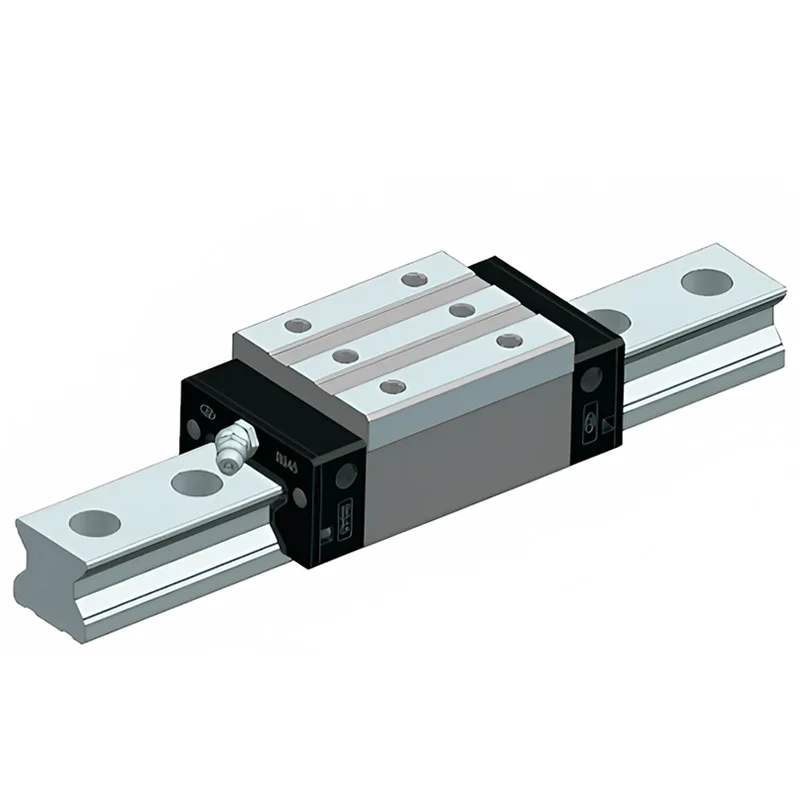

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

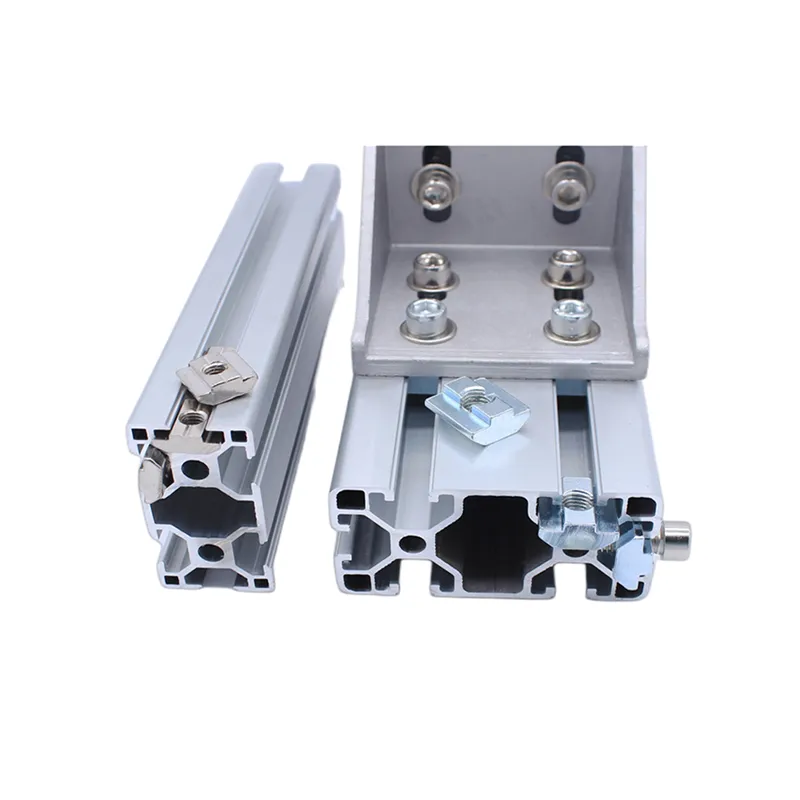

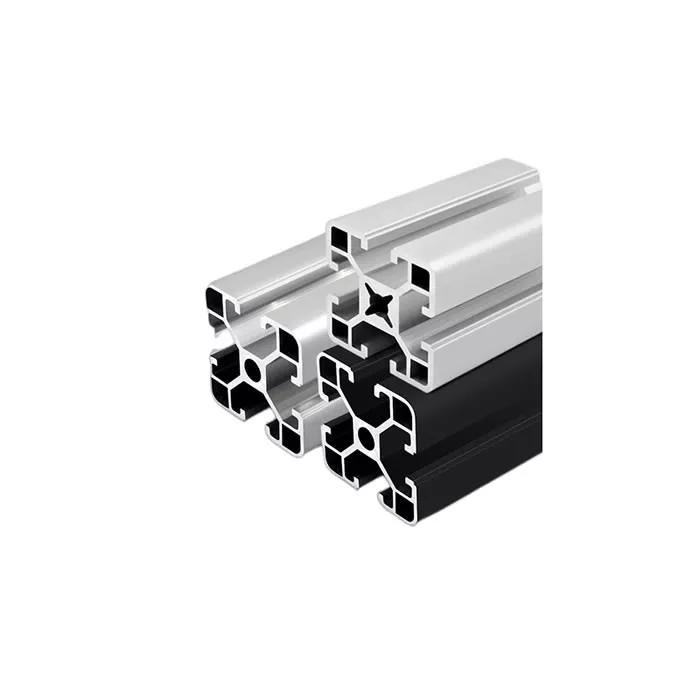

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd