Precautions for using ball screw

(1)Lubrication

When using Ball Screws, it is necessary to have sufficient lubrication.

If the lubrication is not sufficient, contact with metal may occur,

leading to increased friction and wear, resulting in faults or shortened service life.

The lubricants used for ball screw can be divided into two types:

lubricating oil and lubricating paste.

Generally, in maintenance, the lubrication sound

can increase linearly with the increase of rotational speed,

and when it exceeds 3-5 m/min, oil lubrication is the preferred method.

However, do not forget that there have also been instances of using lubricants that reach 10m/min,

and there are also devices that are suitable for low-cost lubricants.

Generally speaking, in order to fully utilize the function of the ball screw,

a lubricating oil of around 5m/min is the most appropriate.

(2)Dustproof

Ball screw, like rolling bearings,increases wear and sometimes leads to damage when foreign objects or moisture are mixed in.

For example, due to the working environment,

working machinery may be mixed with chips or cutting oil.

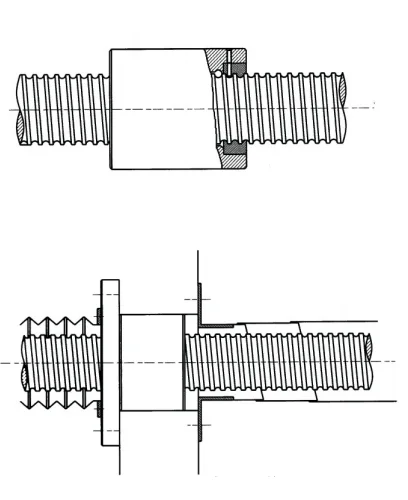

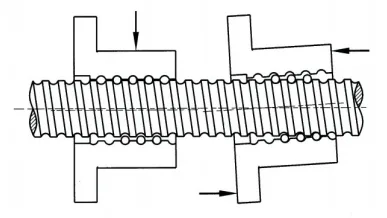

Therefore, when there is a possibility of foreign objects being mixed from the outside,

the screw shaft should be completely covered

with folded cloth (snake belly type) or sleeve expansion tube, as shown in the figure.

(3)Biased load

When the phenomenon of biased load occurs,

it will directly affect the lifespan and noise of the screw,

and it is often due to the feeling of rough operation.

If the smoothness of the screw is different when it is unloaded and after assembly,

in addition to paying attention to the accuracy of the screw itself,

it is mostly due to poor combination accuracy that biased load occurs.

How to avoid roller bearing failures

How to avoid roller bearing failures

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd