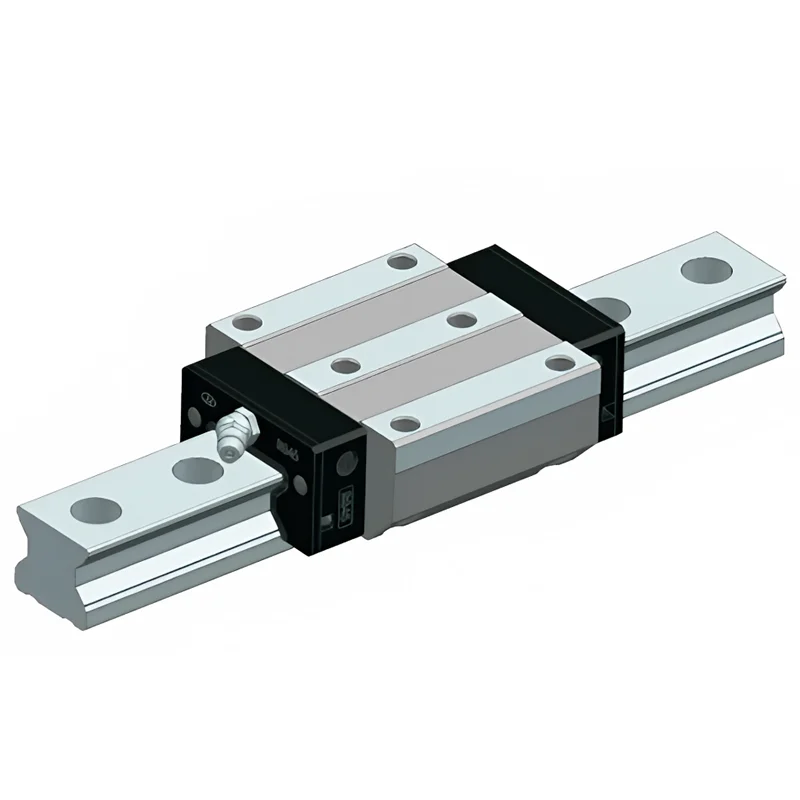

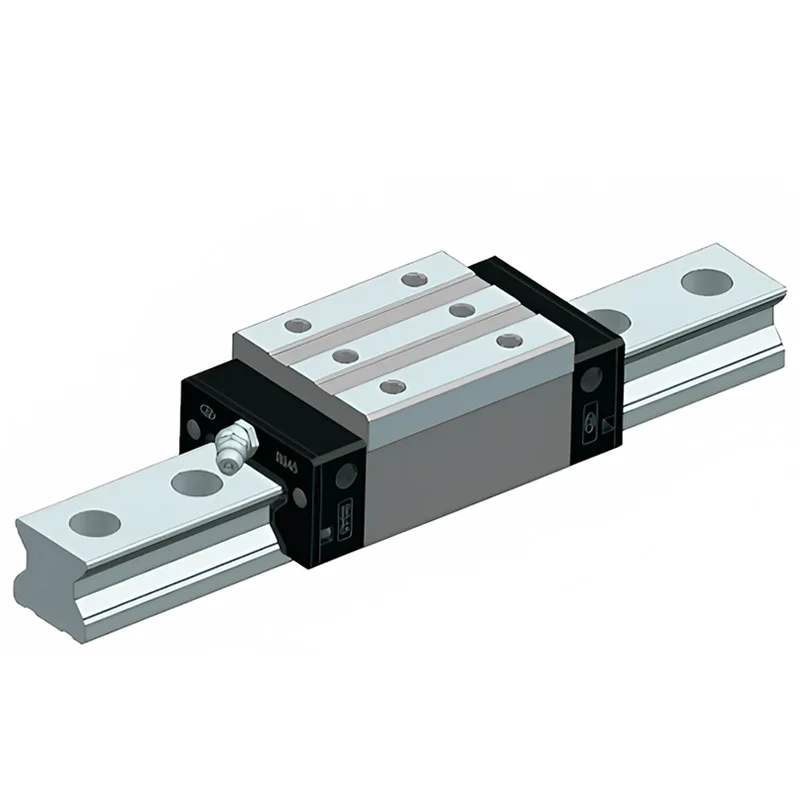

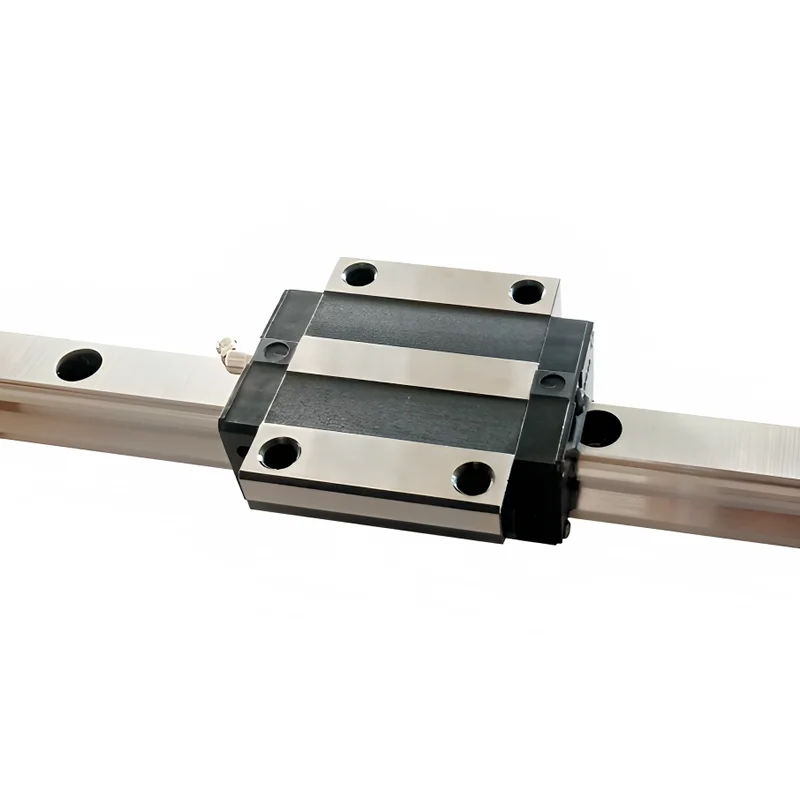

RGW-CC/RGW-HC,Linear Motion,Linear Guideways

Features of the RG Series Linear Guideway

The design principle of RG series linear guide is the same as that of HG series linear guide,

but the rollerreplaces the steel ball, increasing the rolling contact line length,

and at the same time,The diagonaldistance between the two lanes is increased,

further increasing the torque and rigidity. However, whenthere is lateral torque,

the steel ball guide will have a small amount of Angle buffer adjustment,

but theroller guide will only produce a small amount of roller variation,

still maintaining high accuracy andrigidity. Under the superposition of the two,

load capacity, rigidity, life are far beyond the ball guide,

In addition the requirements for the erection datum

plane of roller linear guide is higher than ball linearguide.

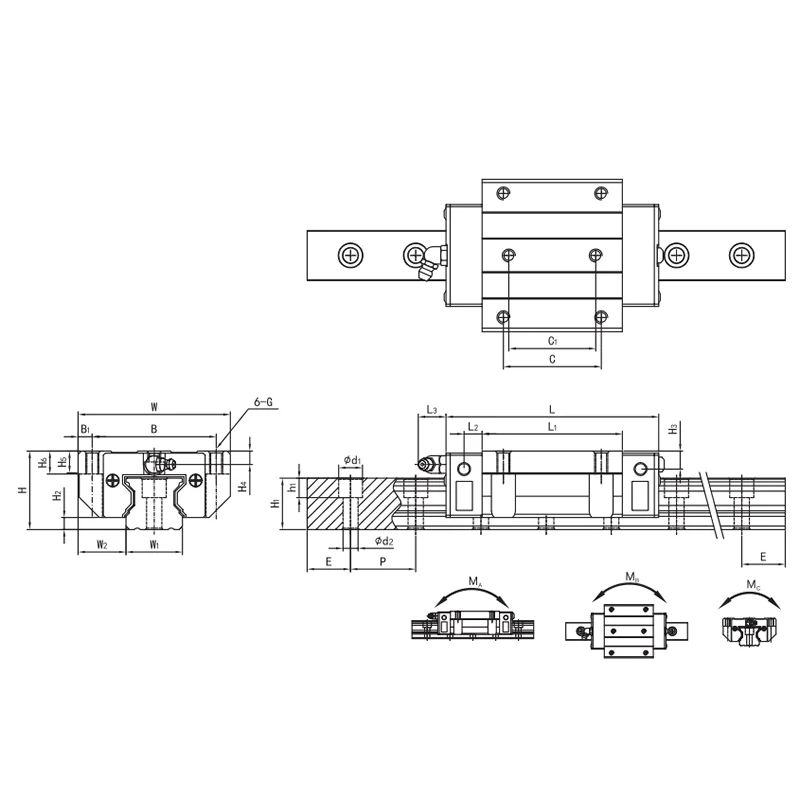

| Model No | Dimensions of Assembly (mm) | Dimensions of block (mm) | Dimensions of rial (mm) | Mounting Bolt or rail | Basic Dynamic Load Rating | Basic Static Load Rating | Static Rated Moment | Weight | s t o c k | ||||||||||||||||||||||

| MA kN-m | MB kN-m | MC kN-m | Block kg | Rail kg/m | |||||||||||||||||||||||||||

| H | H2 | W2 | W | B | B1 | C | C1 | L1 | L | L2 | L3 | G | H5 | H6 | H4 | H3 | W1 | H1 | d1xd2xh1 | P | E | (mm) | C(kN) | C,(kN) | |||||||

| SRGW15CC | 24 | 4 | 16 | 47 | 38 | 4.5 | 30 | 26 | 45 | 68 | 4.7 | 5.3 | M5 | 6 | 6.95 | 3.6 | 6.1 | 5 | 6.5 | 7.5x4.5×5.7 | 30 | 20 | M4×16 | 11.3 | 24 | 0.173 | 0.173 | 0.311 | 0.22 | 1.8 | 0 |

| SRGW20CC | 30 | 5 | 21.5 | 63 | 53 | 5 | 40 | 35 | 57.5 | 86 | 6 | 5.3 | M6 | 8 | 10 | 4.3 | 4.3 | 20 | 21 | 9.5×6x8.5 | 30 | 20 | M5×20 | 21.3 | 46.7 | 0.46 | 0.46 | 0.647 | 0.47 | 2.76 | 0 |

| SRGW20HC | 77.5 | 106 | 26.9 | 63 | 0.837 | 0.837 | 0.872 | 0.63 | 0 | ||||||||||||||||||||||

| SRGW25CC | 36 | 5.5 | 23.5 | 70 | 57 | 6.5 | 45 | 40 | 64.5 | 97.9 | 7.25 | 12 | M8 | 9.5 | 10 | 6.2 | 6 | 23 | 23.6 | 11×7×9 | 30 | 20 | M6×20 | 27.7 | 57.1 | 0.605 | 0.605 | 0.758 | 0.72 | 3.08 | 0 |

| SRGW25HC | 81 | 14.4 | 33.9 | 73.4 | 0.99 | 0.991 | 0.975 | 0.9 | 0 | ||||||||||||||||||||||

| SRGW30CC | 42 | 6 | 31 | 90 | 72 | 9 | 52 | 44 | 71 | 9.8 | 8 | 12 | M10 | 9.5 | 10 | 6.5 | 7.3 | 28 | 28 | 14×9×12 | 40 | 20 | M8x25 | 39.1 | 82.1 | 1.06 | 1.06 | 1.445 | .16 | 4.41 | 0 |

| SRGW30HC | 93 | 31.8 | 48.1 | 105 | 1.712 | 1.712 | 1.846 | .52 | 0 | ||||||||||||||||||||||

| SRGW35CC | 48 | 6.5 | 33 | 00 | 82 | 9 | 62 | 52 | 79 | 124 | 10 | 12 | M10 | 12 | 13 | 9 | 2.6 | 34 | 30.2 | 14×9×12 | 40 | 20 | M8×25 | 57.9 | 105.2 | 1.44 | 1.44 | 2.17 | 1.75 | 6.06 | 0 |

| SRGW35HC | 6.5 | 51.5 | 73.1 | 14.2 | 2.6 | 2.6 | 2.93 | 2.40 | 0 | ||||||||||||||||||||||

| SRGW45CC | 60 | 8 | 37.5 | 120 | 100 | 10 | 80 | 60 | 106 | 53.2 | 10 | 12.9 | M12 | 14 | 15 | 10 | 14 | 45 | 38 | 20x14x17 | 52.5 | 22.5 | M12×35 | 92.6 | 178.8 | 3.05 | 3.05 | 4.52 | 3.43 | 9.97 | 0 |

| SRGW45HC | 39.8 | 187 | 116 | 230.9 | 5.47 | 5.47 | 6.33 | 4.57 | 0 | ||||||||||||||||||||||

| SRGW55CC | 70 | 10 | 43.5 | 140 | 116 | 12 | 95 | 70 | 25.5 | 83.7 | 12.5 | 12.9 | M14 | 16 | 17 | 12 | 7.5 | 53 | 44 | 23×16×20 | 60 | 30 | M14x45 | 130.5 | 252 | 5.4 | 5.4 | 8.01 | 5.43 | 13.98 | 0 |

| SRGW55HC | 73.8 | 232 | 167.8 | 348 | 10.25 | 10.25 | 11.15 | 7.61 | 0 | ||||||||||||||||||||||

| SRGW65CC | 90 | 12 | 53.5 | 170 | 142 | 14 | 110 | 82 | 160 | 232 | 15.8 | 12.9 | M16 | 22 | 23 | 15 | 15 | 63 | 53 | 26×18×22 | 75 | 35 | M16x50 | 213 | 411.6 | 11.59 | 11.59 | 16.20 | 11.63 | 20.22 | 0 |

| SRGW65HC | 223 | 295 | 275.3 | 572.7 | 22.17 | 22.17 | 22.55 | 16.58 | 0 | ||||||||||||||||||||||