What Causes Stripped Screws

Encountering a stubborn screw that refuses to budge can be a frustrating experience, especially when your screwdriver starts to spin freely in the screw's head.

This common issue often arises due to various factors, each contributing to the dreaded phenomenon of stripped screws.

Corrosion Woes:

A primary culprit behind stripped screws is corrosion. Typically composed of steel, screws are robust but susceptible to corrosion when exposed to moisture.

The steel's iron alloy nature makes it strong, yet the onset of corrosion can compromise the head's integrity.

As corrosion sets in, the once uniform and stable recess for your screwdriver becomes irregular, leading to ineffective gripping.

Over-Tightening Struggles:

Over-tightening ranks high among the reasons for stripped screws. While turning screws clockwise with a screwdriver tightens them,

it's crucial to exercise restraint. Once the screw head is flush with the surface, further turning can result in stripping.

Knowing when to stop is essential to prevent this common issue.

The Right Tool for the Job:

Using the correct screwdriver is paramount. Matching the screw's recess type—whether Phillips, slotted, or another—with the appropriate screwdriver is crucial.

Size matters too; using a screwdriver that is too big or too small increases the risk of stripping.

Precision in tool selection is key to successful screw manipulation.

Quality Matters:

The quality of screws plays a pivotal role. Cheap screws are more prone to stripping, exhibiting worn and degraded head recesses.

Investing in high-quality screws can save you from the hassle of dealing with stripped screws, ensuring durability and longevity.

Mastering the Technique:

Improper tightening techniques contribute significantly to stripped screws.

Whether using a Phillips or flat-head screwdriver, the forward push method is recommended.

Ensuring that the screwdriver aligns directly in front of the screw during the turning process minimizes the risk of wearing down the screw's head recess.

Soft Material Dilemma:

Installing screws in soft materials introduces another risk factor for stripping.

While soft materials offer less resistance during installation, this very characteristic makes screws more susceptible to stripping.

Awareness of the material's softness is crucial, prompting a delicate touch during installation to prevent unnecessary damage.

In Conclusion

Understanding the various factors that contribute to stripped screws empowers individuals to take preventive measures.

Whether it's avoiding over-tightening, using the right tools, opting for quality screws, mastering proper techniques,

or being mindful of installation materials, a comprehensive approach can save both time and frustration in dealing with this common DIY challenge.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

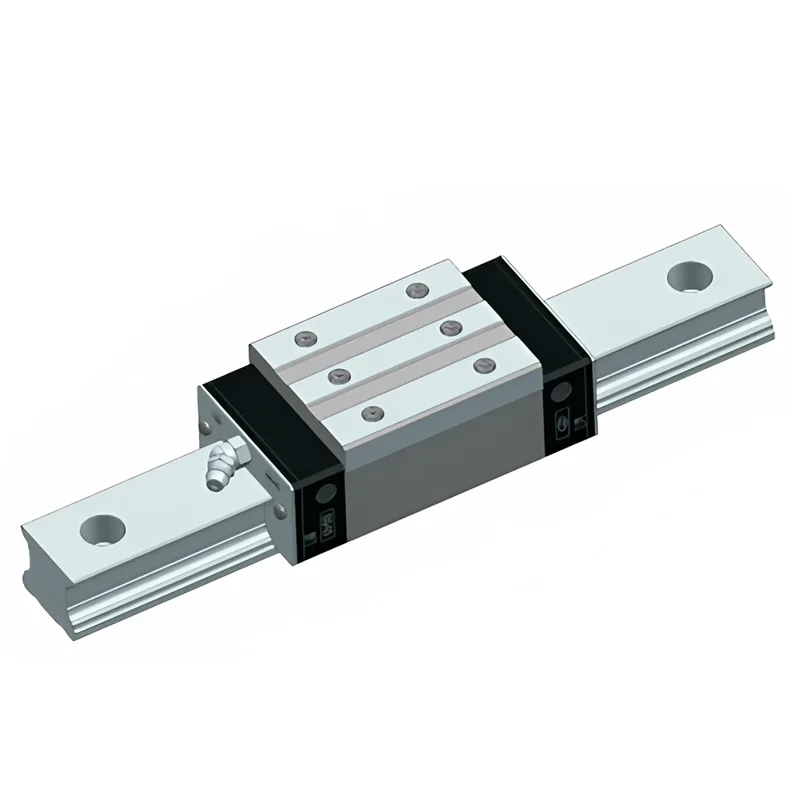

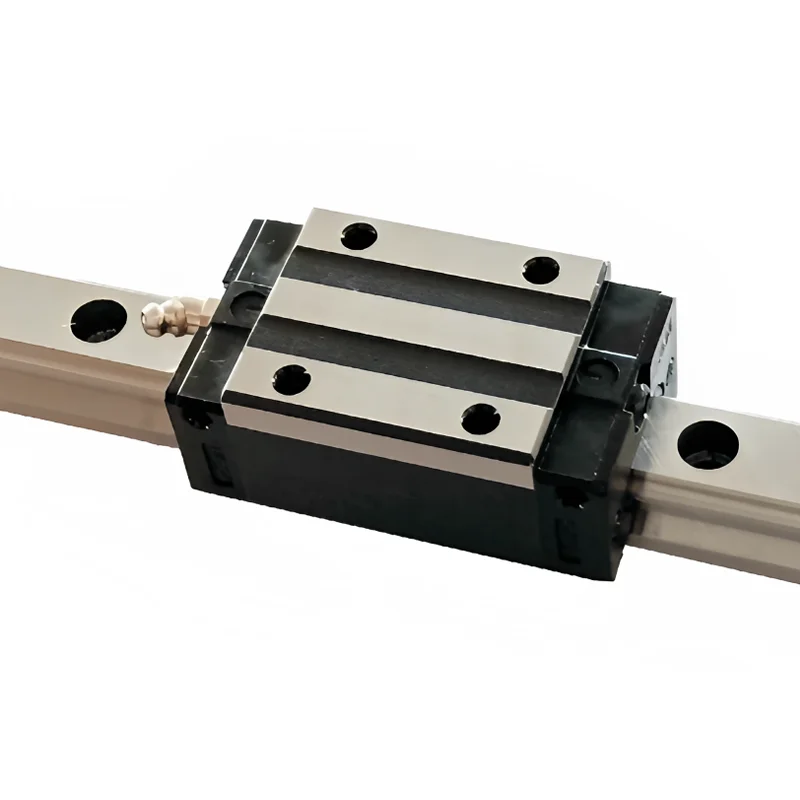

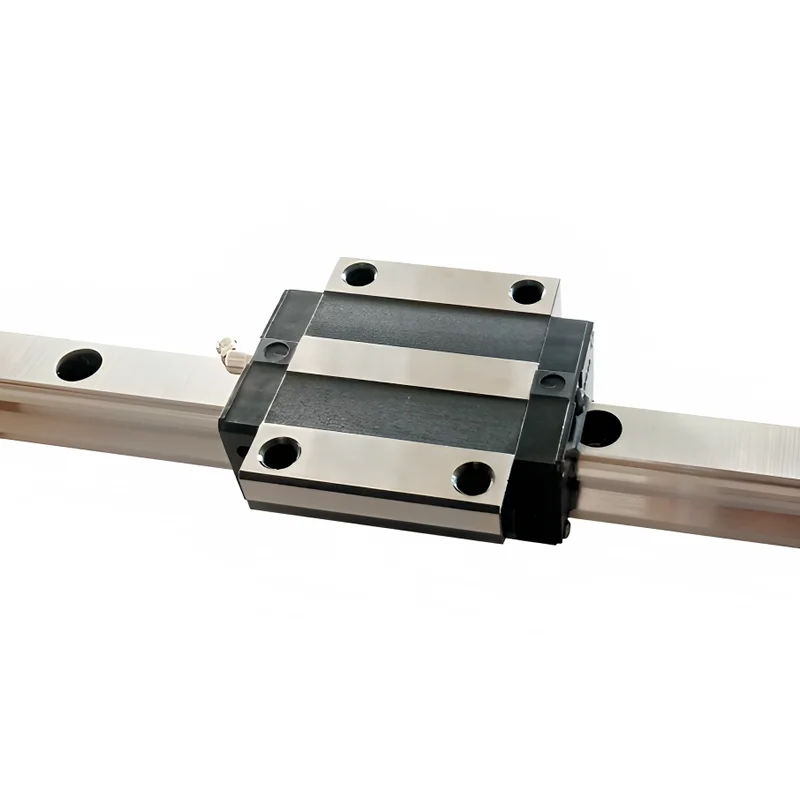

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

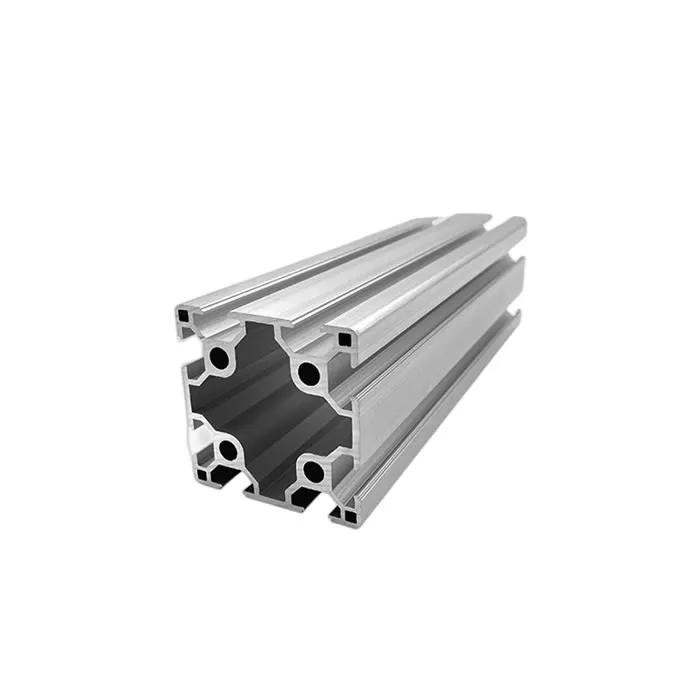

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS