How to Make a Lead Screw

Making a lead screw involves precision machining and threading processes.

A lead screw is a threaded rod or shaft used for converting rotational motion into linear motion.

Materials and Tools:

Metal rod or shaft (material depends on application, commonly stainless steel, brass, or aluminum)

Lathe machine

Cutting tools (parting tool, turning tool)

Threading tool

Calipers

Thread gauge

Micrometer

Sandpaper or emery cloth

Cutting oil

Steps:

Choose the Material:

Select a suitable material for your lead screw based on factors like strength, corrosion resistance, and application requirements.

Cut the Rod:

Use a lathe machine to cut the metal rod to the desired length. Ensure the cut is clean and perpendicular to the axis of the rod.

Turning:

Mount the rod in the lathe chuck and use turning tools to shape the rod to the desired diameter. Measure the diameter using calipers and adjust as necessary.

Facing:

Use a facing tool to create a smooth and flat surface at each end of the rod.

Threading:

Set up the lathe for threading. Use a threading tool to cut the threads on the rod. The pitch of the threads determines the lead of the screw.

Measure the pitch with a thread gauge to ensure accuracy.

Check Thread Dimensions:

Use a micrometer to check the pitch diameter and ensure it meets the specifications. Adjust the lathe if necessary.

Finish the Threads:

Use sandpaper or emery cloth to smooth the threads and remove any burrs. This step is crucial for achieving a precise fit and reducing friction.

Cut to Length:

If your lead screw has a specific length requirement, use a parting tool to cut the screw to the desired length.

Clean and Lubricate:

Clean the lead screw thoroughly to remove any debris or cutting oil. Apply a suitable lubricant to reduce friction and improve performance.

Testing:

Test the lead screw to ensure it functions as intended. Check for smooth movement and proper engagement with any mating components.

It's important to note that making a lead screw requires skill and precision machining equipment.

If you don't have experience with lathe operations, consider seeking assistance from a professional machinist or a machine shop.

Additionally, safety precautions should be followed when using machining tools and equipment.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

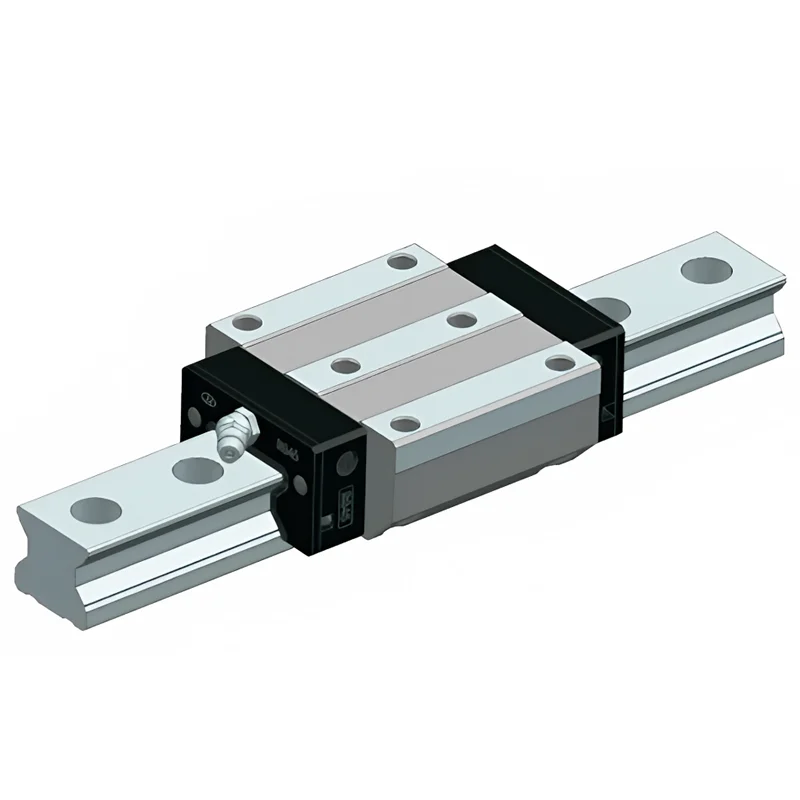

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS