Rod End Bearings In Automobiles

Rod End Bearings, also known as spherical plain bearings or Heim joints, are commonly used in automobiles for various applications.

They provide a flexible connection between two moving parts, allowing for angular misalignment and smooth articulation.

Here are some key points about rod end bearings in automobiles:

1. Purpose: Rod end bearings are primarily used in automotive suspension systems, steering linkages, and control arms.

They allow for controlled movement and articulation while maintaining stability and reducing friction.

2. Construction: Rod end bearings consist of an inner ring with a spherical or cylindrical bore,

an outer ring with a spherical or cylindrical surface, and a ball or roller element that facilitates

movement between the inner and outer rings. They are typically made of steel or other durable

materials to withstand the demands of automotive applications.

3. Features: Rod end bearings have several features that make them suitable for automotive use.

They often have a threaded shank or stud on one end, allowing for easy attachment to other components.

They may also have provision for lubrication to reduce wear and friction.

4. Benefits: Rod end bearings offer several advantages in automotive applications.

They can accommodate angular misalignment, axial and radial loads, and oscillating or rotating movements.

They provide smooth articulation, allowing for precise steering and suspension control.

Additionally, they help absorb shocks and vibrations, enhancing overall ride quality and comfort.

5. Maintenance: Like other bearings, rod end bearings require periodic maintenance.

This may involve greasing or lubricating the bearing to ensure smooth operation and prevent premature wear.

Regular inspection is also necessary to detect any signs of damage or excessive play.

6. Variations: Rod end bearings come in various configurations and sizes to suit different automotive applications.

They can be male or female-threaded, have different load capacities and angles of articulation,

and may incorporate seals or boots for added protection against contaminants.

7. Replacement: If a rod end bearing in an automobile shows signs of wear, such as excessive play or noise,

it should be replaced promptly. It is important to use the correct replacement bearing specified

by the vehicle manufacturer to ensure proper fit and performance.

Remember, the specific usage and number of rod end bearings in an automobile can vary depending on the

vehicle's design and components. For accurate information, it is advisable to consult the vehicle's manufacturer

or refer to the technical documentation related to the specific car model.

How to avoid roller bearing failures

How to avoid roller bearing failures

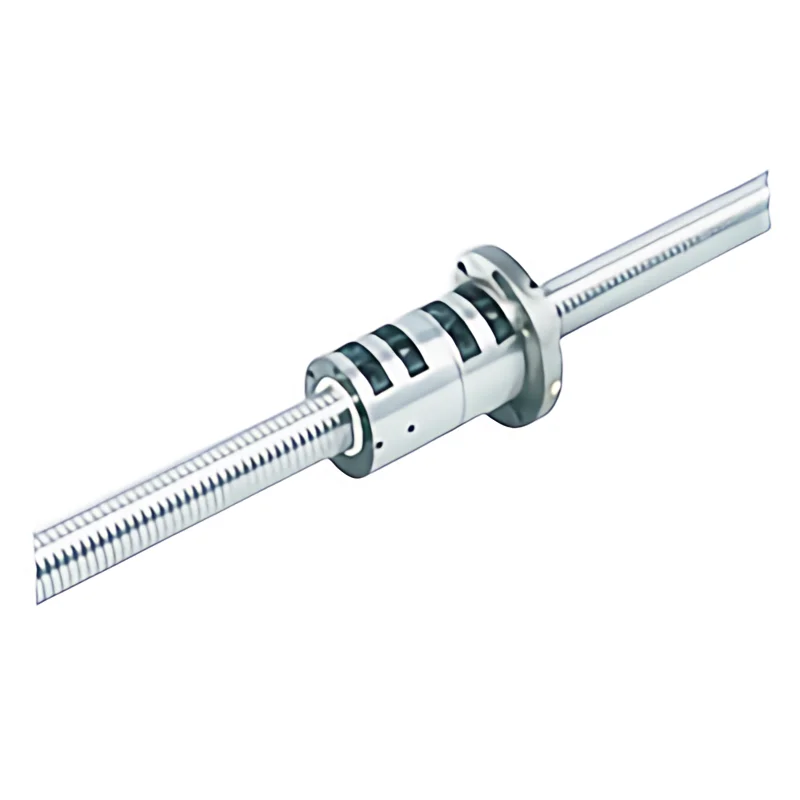

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

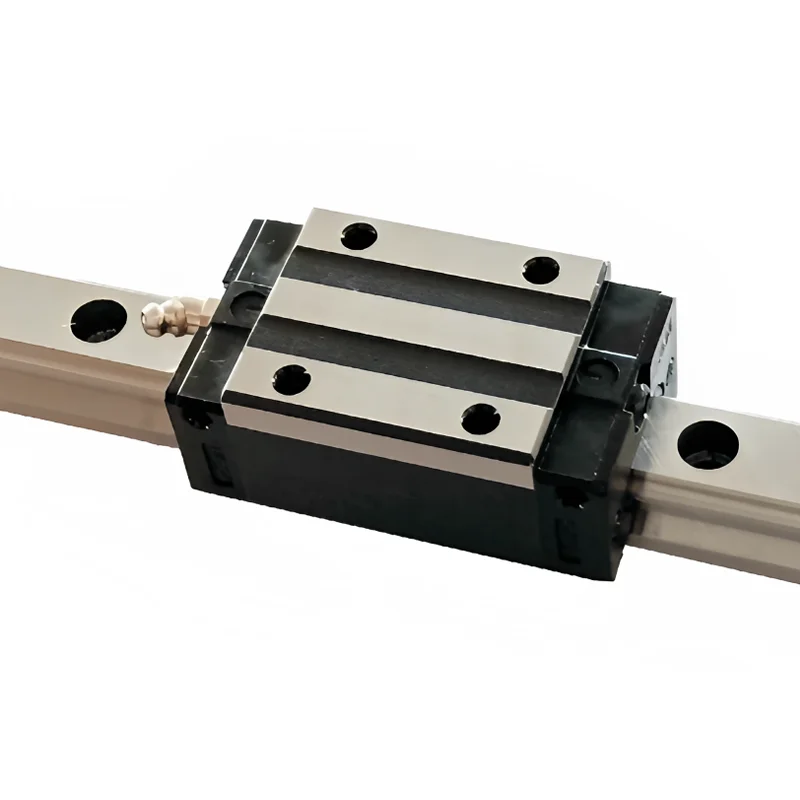

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd