Modern Methods for Bearing Temperature Control

Heating a bearing can be necessary for various reasons, such as installing or removing it from a shaft.

However, it's essential to be cautious to avoid causing damage to the bearing during the heating process.

Here are some general guidelines:

Use the Right Temperature:

Excessive heat can damage the bearing material, so it's crucial to use the correct temperature.

Typically, a controlled heating device such as an induction heater is used to ensure precise temperature control.

Follow the manufacturer's recommendations for the specific type of bearing you are working with.

Uniform Heating:

Ensure that the heat is applied uniformly across the bearing. Non-uniform heating can lead to uneven expansion and potential damage.

Rotate the bearing during the heating process to distribute the heat evenly.

Avoid Open Flames:

Never use an open flame to heat a bearing. Open flames can cause localized hot spots and may lead to overheating or damage.

Induction heaters or other controlled heating methods are preferred.

Monitor Temperature:

Use a temperature-indicating device, such as a thermometer or an infrared thermometer, to monitor the temperature of the bearing.

This helps prevent overheating and ensures that the bearing reaches the desired temperature without exceeding it.

Preheat Components:

If applicable, preheat surrounding components to reduce temperature differentials between the bearing and its housing or shaft.

This can help prevent thermal shock.

Protect Seals and Lubricants:

If the bearing has seals or is lubricated with grease, it's essential to protect these components from excessive heat.

Remove seals or use heat-resistant materials to shield them during the heating process.

Control Heating Time:

Limit the heating time to the minimum necessary to achieve the desired expansion for installation or removal.

Prolonged exposure to high temperatures can compromise the bearing's integrity.

Allow for Thermal Expansion:

After heating, allow the bearing to expand uniformly before attempting to install or remove it.

Rushing the process may result in damage.

Use Proper Tools:

When installing or removing a bearing, use suitable tools designed for the purpose.

This helps prevent unnecessary stress or damage to the bearing.

Always refer to the manufacturer's guidelines for the specific bearing you are working with,

as different bearings may have specific requirements and limitations.

Additionally, follow safety precautions and use personal protective equipment as needed during the heating process.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

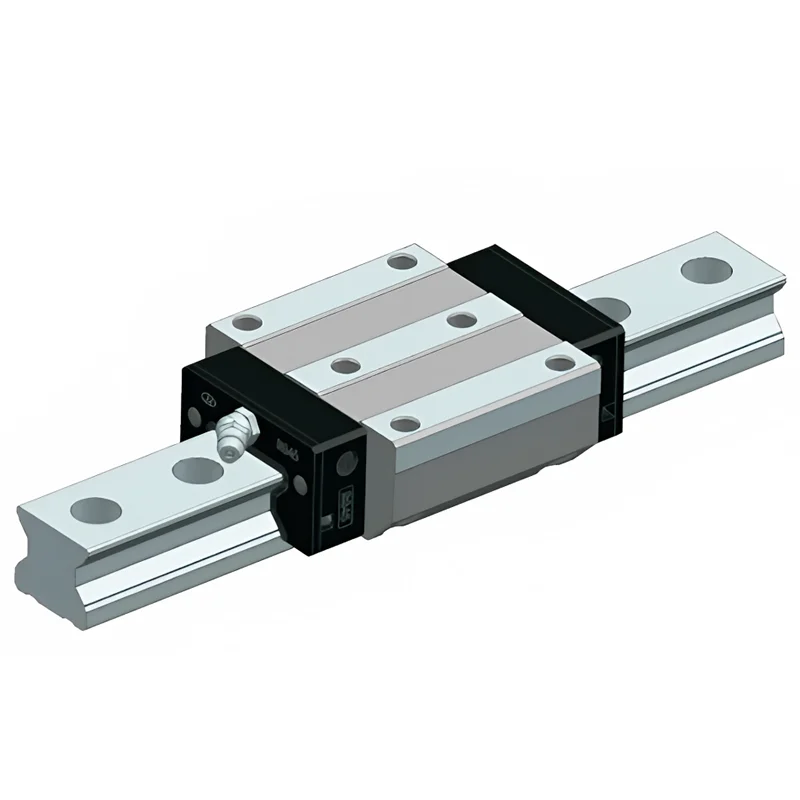

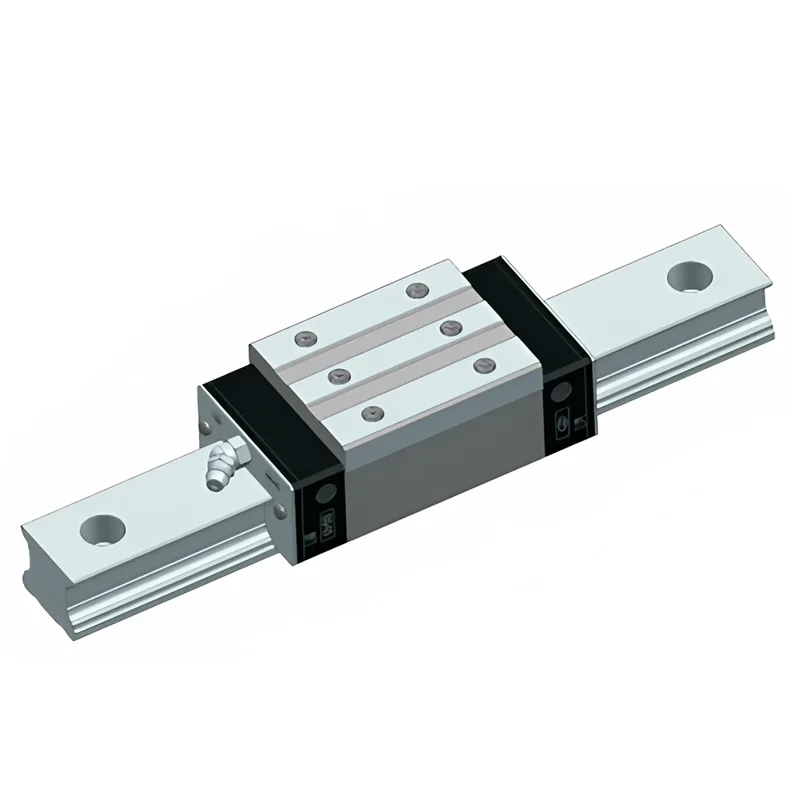

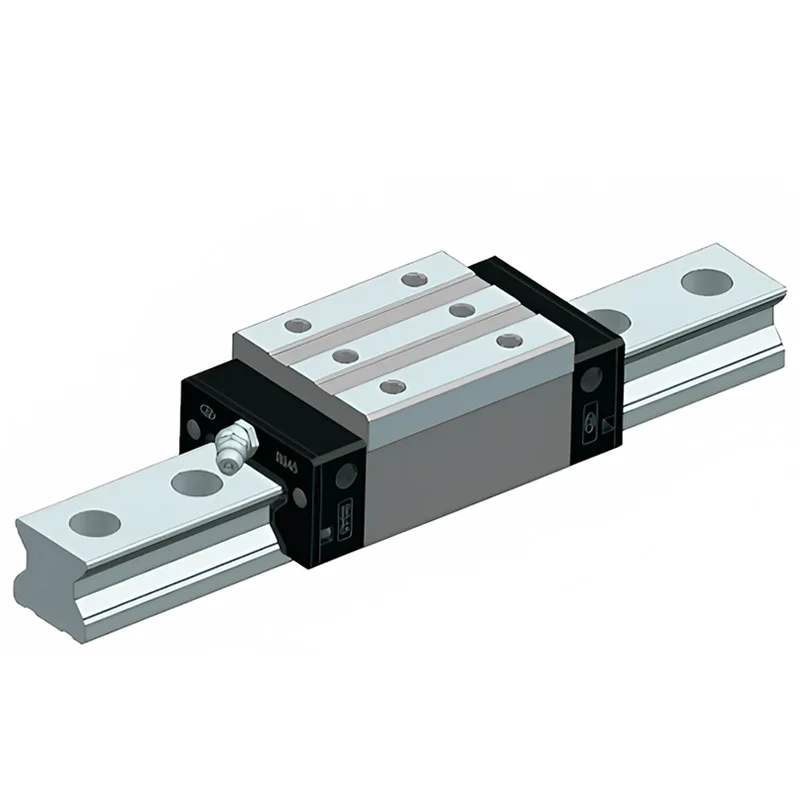

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

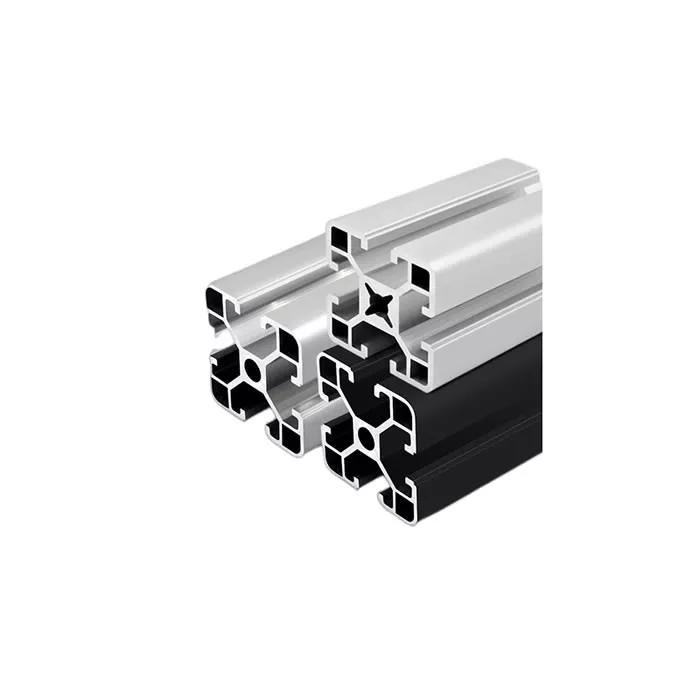

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS