What are the Consequences of Over-Torquing Screws?

Over-torquing screws refers to applying too much force when tightening them. This can have several negative consequences:

Stripped Threads

Applying excessive torque can cause the threads on either the screw or the material it's being screwed into to become stripped.

This means that the threads become damaged or deformed, reducing their ability to grip and hold the screw in place securely.

Material Damage

Over-torquing can lead to damage to the material around the screw, especially in softer materials.

This damage might include cracking, breaking, or deformation of the material, which can compromise the structural integrity of the assembly.

Bolt Stretch

In the case of bolts, over-torquing can cause them to stretch. Bolts are designed to provide a specific amount of tension when tightened to a certain torque.

Exceeding this torque can cause the bolt to stretch beyond its elastic limit, leading to permanent deformation and reduced strength.

Failure of Components

Over-torquing can lead to the failure of components in the long run. If screws or bolts are tightened beyond their recommended torque values,

it can affect the overall performance and reliability of the assembly. This may result in unexpected failures or malfunctions.

Uneven Stress Distribution

Over-torquing can cause uneven stress distribution across the joint or assembly.

This can lead to concentrated stress points, making the structure more susceptible to fatigue and reducing its overall durability.

Difficulty in Removal

Over-torqued screws or bolts can be challenging to remove.

The excessive force applied during tightening may cause the threads to bind or seize,

making it difficult to loosen the fastener without causing further damage.

To avoid these issues, it's crucial to follow the manufacturer's recommended torque specifications for screws, bolts, and other fasteners.

Using a torque wrench can help ensure that the correct amount of force is applied during the tightening process, preventing over-torquing and its associated

problems.

How to avoid roller bearing failures

How to avoid roller bearing failures

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

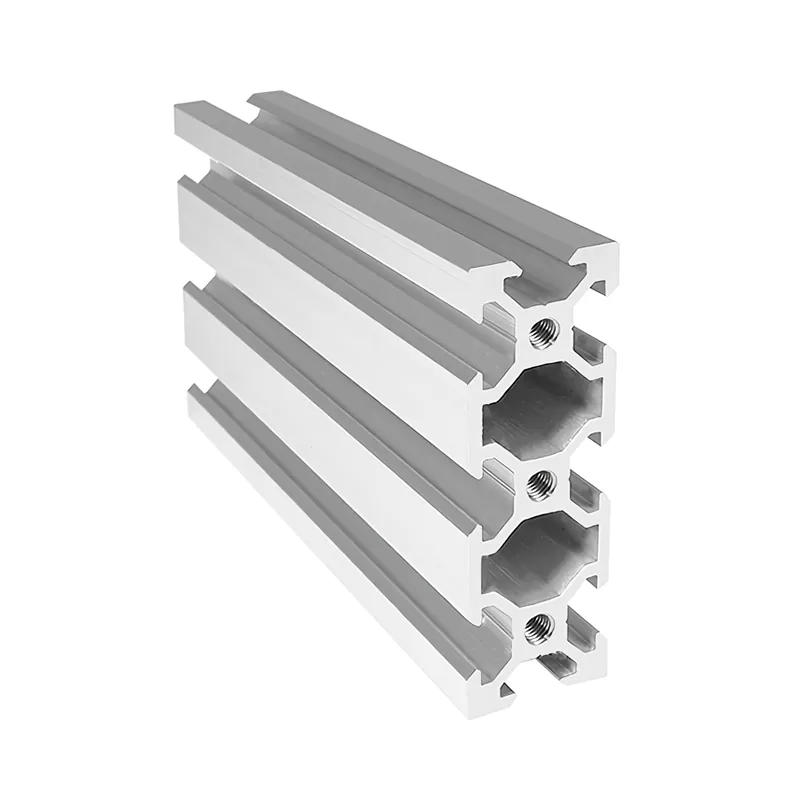

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd