6 Steps to Proper Industrial Bearing Removal and Replacement

Regular maintenance of industrial bearings is crucial to ensure the optimal functionality and efficiency of your equipment.

Bearing failure can lead to equipment breakdowns, resulting in costly downtimes for your facility.

Effective maintenance schedules for industrial bearings should encompass routine inspections, cleanings, and regular lubrication.

Insufficient lubrication is a primary cause of premature bearing failure, making proper lubrication a critical aspect of maintenance.

Adhering to a maintenance program and replacing bearings preemptively when necessary can significantly extend the service life of your manufacturing

equipment.

Therefore, understanding the proper bearing removal and replacement procedures is essential to ensure efficient operations and minimize downtime.

6 Steps for Proper Industrial Bearing Removal and Replacement:

To successfully remove and replace an industrial bearing, it's essential to follow a systematic process. Here are the steps:

Gather Tools and Safety Gear: Collect necessary tools and ensure safety precautions are in place.

Remove Old Bearing: Clean the area, remove locking mechanisms, and safely extract the old bearing. Inspect for damage.

Prepare Replacement Bearing: Clean and lubricate the new bearing as needed, ensuring compatibility.

Prepare Shaft and Housing: Clean and inspect both surfaces, checking for proper tolerances and smoothness.

Install New Bearing: Align and press-fit the replacement bearing, ensuring it rotates freely. Consider thermal installation methods for tight fits.

Post-Installation Checks: Inspect for damage, ensure proper lubrication, and conduct a test run. Record replacement in maintenance logs.

Following these steps diligently can help maintain equipment reliability and prolong bearing service life, ultimately reducing downtime and operational costs.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

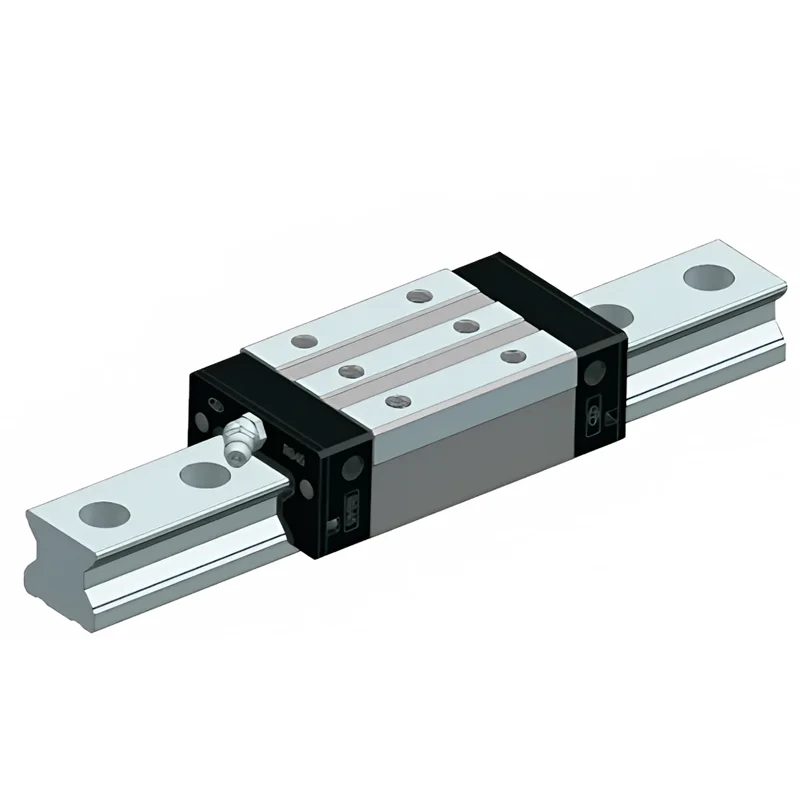

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

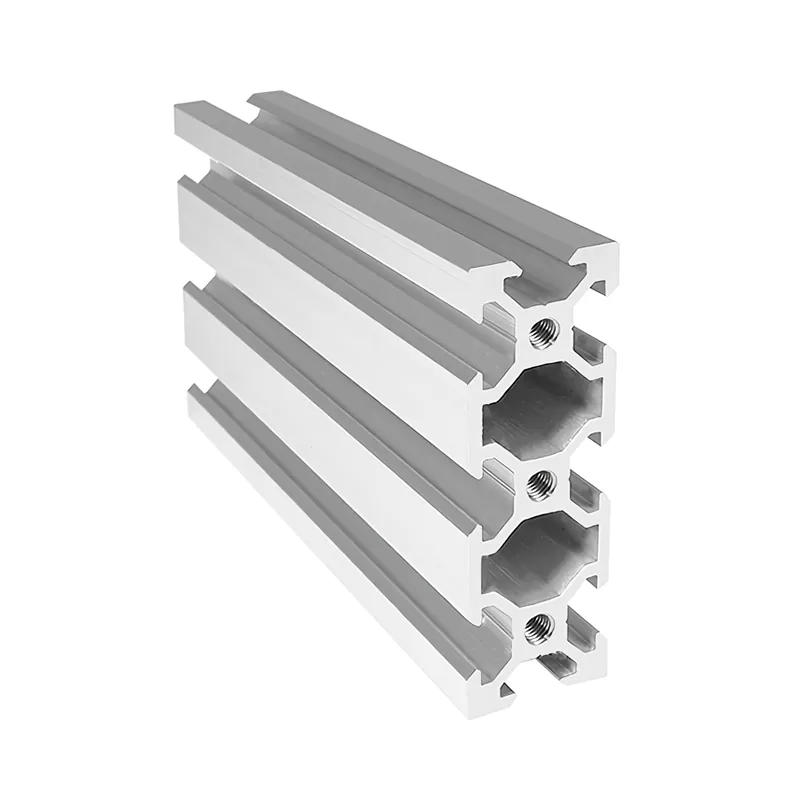

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS