The Advantages of Small Fasteners in Modern Manufacturing

Improved assembly speed:

Small fasteners, such as screws, contribute to faster assembly processes.

They are easy to handle and can be quickly secured in place, leading to more efficient production lines.

This increased speed not only enhances overall manufacturing productivity but also allows companies to meet tight production deadlines.

Enhanced disassembly and maintenance:

Unlike permanent joining methods like welding or adhesives, fasteners provide the advantage of easy disassembly.

This is crucial for products that may require maintenance, repairs, or upgrades throughout their lifecycle.

Using small screws in manufacturing allows for straightforward disassembly and reassembly, reducing downtime and maintenance costs.

Cost-effectiveness:

Small fasteners are often more cost-effective compared to other joining methods.

Welding and adhesives may require specialized equipment and skilled labor, leading to higher production costs.

Fasteners are relatively simple and inexpensive, contributing to overall cost savings in manufacturing processes.

Versatility in material compatibility:

Fasteners can be used with a wide range of materials, including metals, plastics, and composites.

This versatility provides manufacturers with the flexibility to choose the most suitable materials for specific

components without being restricted by the limitations of welding or adhesives.

This adaptability is especially beneficial in industries where diverse materials are used in product manufacturing.

Quality control and precision:

Small fasteners contribute to better quality control in manufacturing.

The use of screws allows for precise alignment and positioning of components during assembly, ensuring that each part is accurately placed.

This precision helps maintain consistent product quality and reduces the likelihood of errors or defects in the final product.

In summary, the benefits of using small fasteners in manufacturing include increased designing flexibility, reduced waste,

lower product weight, improved assembly speed, enhanced disassembly and maintenance, cost-effectiveness,

versatility in material compatibility, and improved quality control and precision.

These advantages collectively contribute to more efficient and economical manufacturing processes across various industries.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

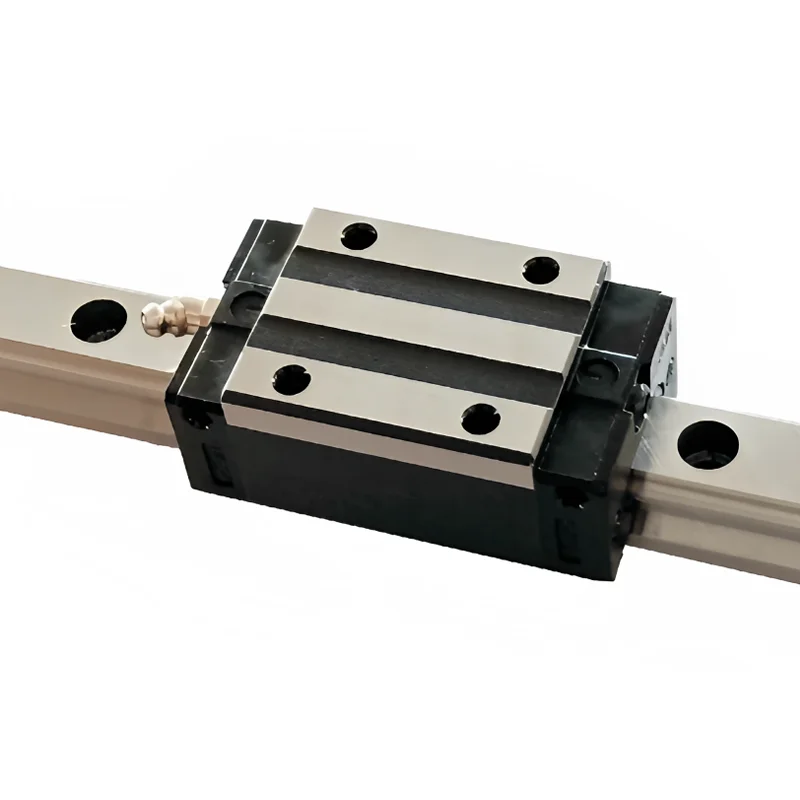

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

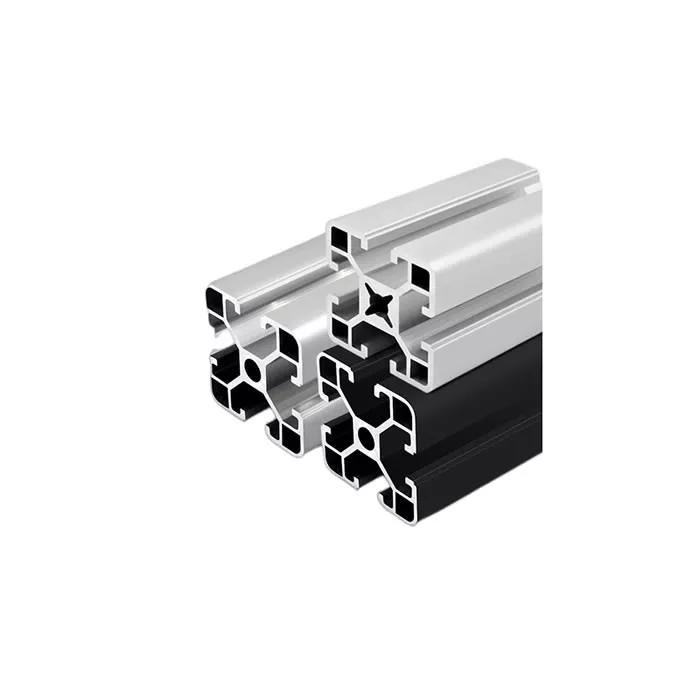

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS