What Is Bearing Brinelling?

Bearing brinelling, derived from the Brinell hardness test is a failure mode in rolling element bearings.

The test involves pressing a hard ball into the surface of a material with a specific force, and the resultant impression is measured to determine its hardness.

Similarly, bearing brinelling refers to the formation of permanent indentations on the raceways of a bearing.

These marks are typically associated with either excessive loads or vibrations that exceed the material's hardness limit.

True brinelling happens when bearings experience excessive static loads or impact, direct consequences of improper handling or mounting

which cause forceful compressions and result in equidistant indentations on both the raceways and the rolling elements.

To prevent true brinelling, handling bearings with care is critical, ensuring that they're not dropped or subjected to excessive force.

Avoiding overload conditions and using proper mounting techniques can minimize the risk during operation.

False brinelling, on the other hand, is not related to static or impact loads but to vibrations transmitted to a bearing when it is stationary.

Even without rotation, the oscillatory motion can generate enough friction to produce wear marks along the raceway paths where the rolling elements rest.

To mitigate false brinelling, it's important to isolate stationary bearings from sources of vibrations and to secure stationary shafts from movement during

transportation.

Bearings need to be adequately blocked or supported to restrict their motion within their packaging.

Both types of brinelling defects lead to premature bearing failures, impacting the operational efficiency of machinery.

Bearings suffering from these conditions tend to exhibit increased noise, and higher vibration levels, and ultimately,

can result in machinery breakdown due to the accelerating wear and tear on the rolling elements and raceways.

Careful installation, appropriate handling, and preventive maintenance are key to prolonging bearing life and preventing brinelling.

Utilizing the correct tools for installing bearings, applying appropriate loads, and ensuring proper alignment can also help avoid these problems.

Regular inspections can identify early signs of wear, allowing for timely interventions that may prevent more serious damage and costly repairs in the future.

In summary, bearing brinelling is a significant cause of bearing failure, and understanding its forms and prevention can be

crucial in maintaining the functionality and longevity of bearings in various industrial applications.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

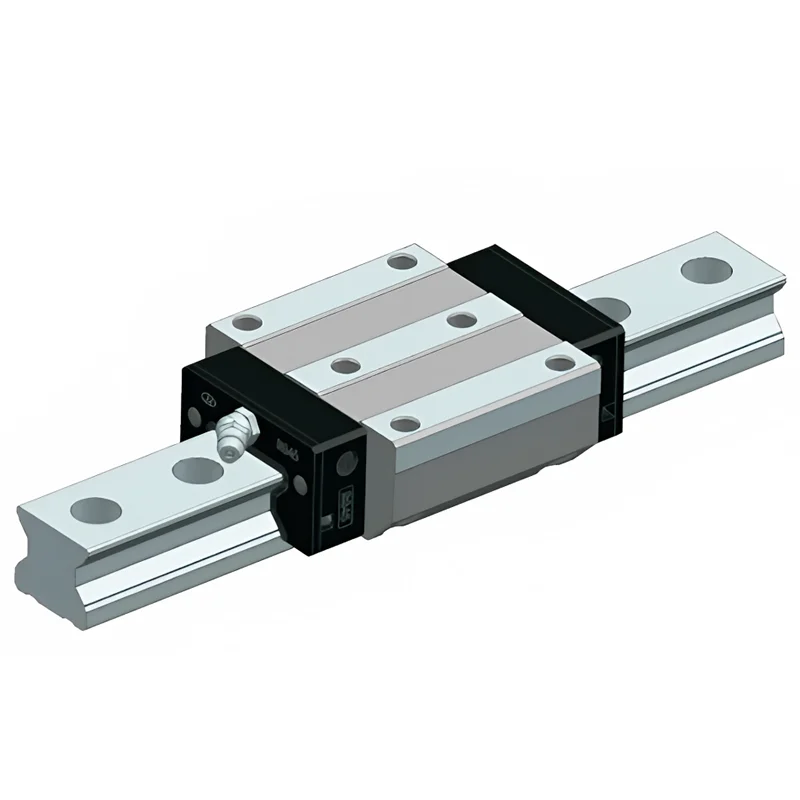

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS