Precision and Efficiency in Motion: Understanding 8/12/16mm Lead Screw Ball Screws

In modern industrial applications, precision motion control is a critical component of machinery efficiency.

Among the most common solutions for converting rotary motion into linear motion are lead screws and Ball Screws.

These components are widely used in a variety of industries, ranging from manufacturing equipment to precision instruments, due to their excellent performance, low friction, and high precision.

The Basics of Lead Screws and Ball Screws

Lead screws and ball screws are both mechanical devices designed to convert rotary motion into linear motion. At their core, they consist of a threaded rod (the screw) and a nut that travels along the screw. The difference between the two lies primarily in the type of nut used.

Lead screws use a traditional sliding nut, while ball screws incorporate recirculating balls in the nut. These balls roll along the thread of the screw, significantly reducing friction compared to the traditional sliding nut. As the screw rotates, the ball nut moves along the threads, thus translating the rotary motion into linear motion efficiently.

Advantages of Ball Screws

Ball screws have become a preferred solution in applications that require high precision, reversibility, and efficiency. The rolling motion of the balls within the nut leads to significantly lower friction resistance compared to lead screws, which translates to higher efficiency and less wear over time. This feature is especially beneficial in applications involving high-speed motion or heavy loads.

In addition, ball screws are reversible, meaning they can also be used to convert linear motion back into rotary motion. This versatility makes them suitable for a wide range of applications, from machinery that requires precise positioning to systems that need to convert linear motion into rotary force.

Common Applications of Ball Screws

Ball screws are commonly found in various industrial machines, including tool machines and precision machinery. They play a key role in translating the rotary motion of motors into the linear motion required to drive parts such as tables, spindles, and slides. The high precision of ball screws makes them indispensable in industries such as:

- CNC machinery

- Automation equipment

- Robotics

- Medical devices

Furthermore, ball screws are also used in industrial equipment such as lifting systems, conveyors, and even precision instruments where smooth, low-friction operation is a must.

Installation and Accuracy of Ball Screws

To ensure the performance and longevity of ball screws, proper installation and alignment are critical. The following checks are recommended for accurate positioning during installation:

- Circumferential Deviation: Measure the radial deviation of the screw's support part in relation to the axis of the threaded groove surface.

- Coaxiality Check: Verify the coaxiality of the screw’s installation position relative to the screw support axis.

- Squareness of End Face: Ensure the end face of the support part is square relative to the axis of the screw shaft support.

- Reference Surface Alignment: Measure the alignment of the nut’s reference surface or flange mounting surface relative to the screw axis.

- Coaxiality of Nut: Check the coaxiality of the nut's outer circumference relative to the screw axis.

- Parallelism Check: Measure the parallelism of the nut’s outer edge relative to the screw axis.

These checks are crucial for ensuring that the ball screw functions with maximum efficiency, accuracy, and durability.

Conclusion

The 8/12/16mm lead screw and ball screw systems are essential components in modern industrial machinery, offering high precision and low friction operation.

With their ability to convert rotary motion into linear motion efficiently, ball screws play a pivotal role in achieving higher performance in many industries.

By ensuring proper installation and maintenance, the lifespan and accuracy of these systems can be maximized, making them an invaluable asset in machinery design.

How to avoid roller bearing failures

How to avoid roller bearing failures

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

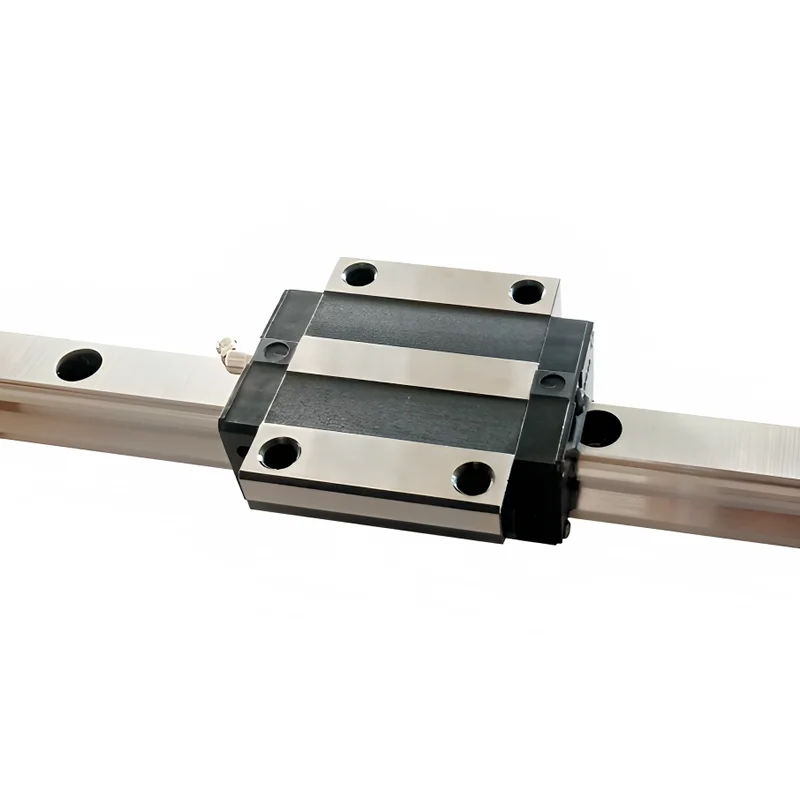

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd