Hot vs Cold Aluminum Extrusion

Aluminum extrusion is a widely used and popular manufacturing process

that involves heating and shaping aluminum billets into specific shapes and sizes.

The process can be done using either hot or cold extrusion.

Both types of extrusion have their unique advantages, disadvantages, and specific applications.

In this article, we will delve into the differences between hot and cold aluminum extrusion.

What is Hot Aluminum Extrusion?

Hot aluminum extrusion is a manufacturing process that involves heating aluminum billets

above their recrystallization temperature, which is approximately 400°C.

The heated aluminum is then forced through a die by a hydraulic ram, which forms it into a specific shape.

The process is known as hot extrusion because the aluminum billet

is heated to high temperatures before it is extruded.

This makes it easier to shape and allows for tighter tolerances than cold extrusion.

What is Cold Aluminum Extrusion?

Cold aluminum extrusion, also known as cold forming,

is a manufacturing process that involves shaping aluminum billets without heating them.

The process is done at room temperature, and the aluminum billet is forced through a die by a hydraulic press.

The resulting product is a cold-extruded aluminum product with tight tolerances.

Differences between Hot and Cold Aluminum Extrusion

Temperature

The most significant difference between hot and cold extrusion is the temperature at which they are performed.

Hot extrusion requires heating the aluminum billet above its recrystallization temperature,

while cold extrusion is done at room temperature.

Hot extrusion uses high temperatures to make the aluminum billet more malleable and easier to shape.

This allows for tighter tolerances and intricate designs.

Cold extrusion, on the other hand, creates products with less precision

than hot extrusion due to the lack of heat and required pressure to shape the billet.

Production Volume

Another critical difference between hot and cold extrusion is their production volume.

Hot extrusion is a slow process compared to cold extrusion, and it requires specialized equipment,

which makes it less popular than cold extrusion. Cold extrusion is faster, less expensive,

and easier to perform on high volumes of production runs.

Surface Finish

Hot extrusion creates a smoother surface finish than cold extrusion due to the higher temperatures involved.

The smoother surface finish makes hot extrusion ideal

for creating products with aesthetic appeal, such as decorative trim pieces.

Cold extrusion may leave a rougher surface finish,

which may require additional machining or surface treatment to achieve the desired smoothness.

Strength and Durability

Hot extrusion creates stronger, denser, and more durable products

than cold extrusion due to the material's heating and cooling under pressure.

The process compresses the aluminum atoms,

which makes the final product stronger and more durable than cold-extruded aluminum.

Cold extrusion, however, is less strenuous on the material and can create unique geometries and designs with aluminum.

Applications

Both hot and cold aluminum extrusion have their specific applications.

Hot extrusion is ideal for creating intricate and complex geometries,

and it is commonly used in the aerospace, automotive, and defense industries.

Cold extrusion is suitable for creating simple shapes that require less precision,

such as pipes and tubes, and it is popular in the construction and HVAC industries.

Conclusion

Whether using hot or cold extrusion, with each method having its advantages and specific applications.

It is essential for manufacturers to understand the differences

between the two methods to choose the best one for their specific needs.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

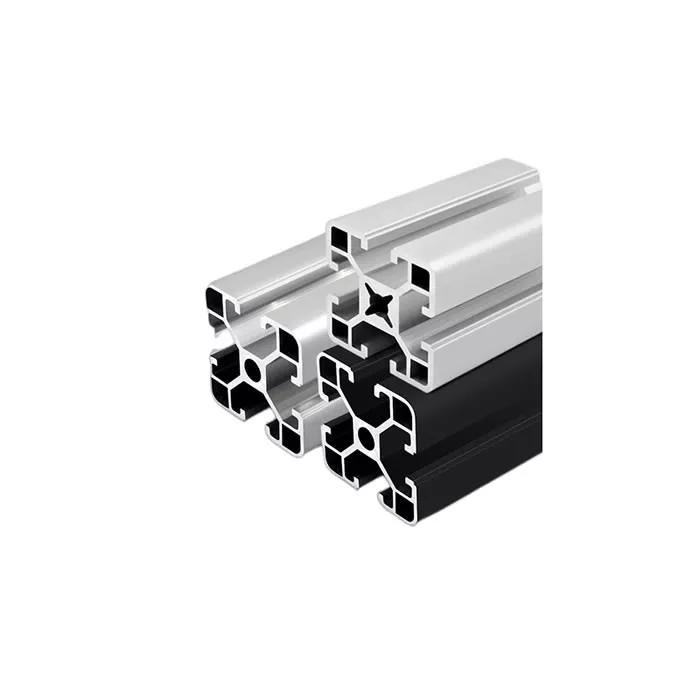

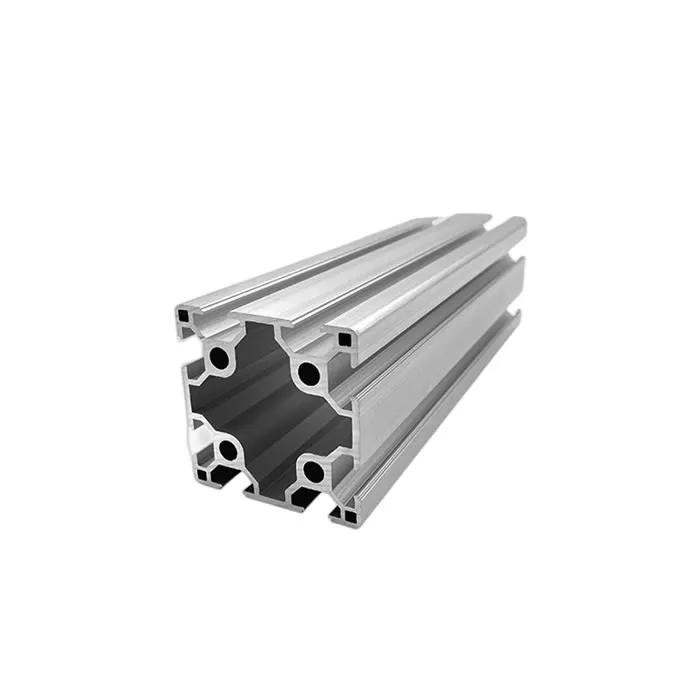

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS