T-Slot Nut learning guide

T-Slot Nuts are a type of fastener that is commonly used in manufacturing and construction projects.

These nuts are specifically designed for use with T-slotted aluminum profiles,

which are used to create structures such as frames, enclosures, and machine guards.

What are T-Slot Nuts?

T-Slot Nuts are fasteners that are designed for use with T-slotted aluminum profiles,

also known as aluminum extrusions. These profiles have a T-shaped slot that runs the length of the profile,

allowing for easy attachment of various components such as brackets, panels, and other accessories.

T-Slot Nuts are specifically designed to fit into these T-slots,

providing a secure fastening point for mounting various components.

Types of T-Slot Nuts

There are several types of T-Slot Nuts available, and selecting the right type

is essential for ensuring a secure and reliable connection.

The most common types of T-Slot Nuts include:

1.Standard T-Nuts

These nuts are the most common type of T-Slot Nut

and are designed to fit snugly into the T-slot of an aluminum profile.

Standard T-nuts are available in a variety of sizes and are typically made from steel or stainless steel.

They are inserted into the T-slot and held in place by tension or friction.

2.Ball Spring Nuts

Ball spring nuts have a spring-loaded ball bearing

that provides a secure grip in the T-slot of the aluminum profile.

These nuts are ideal for applications where vibration or movement is a concern.

3.Drop-in T-Nuts

Drop-in T-nuts have a unique design that allows them to be inserted

into the profile from the end, rather than from the side.

This eliminates the need to slide the nut into the T-slot, making installation faster and easier.

4.Hammer Nuts

Hammer nuts are designed to be used in applications where access to the T-slot from the end is limited.

They are inserted into the profile from the side and are secured in place by using a hammer to strike the nut's tab.

5.Swivel T-Nuts

Swivel T-nuts have a ball joint that allows them to be adjusted to accommodate different angles.

This makes them ideal for use in applications where components need to be mounted at varying angles.

Techniques for Selecting T-Slot Nuts

Selecting the right T-Slot Nut for your specific application

is essential for ensuring a reliable and secure connection.

Here are some techniques for selecting T-Slot Nuts:

1.Consider the application

When selecting T-Slot Nuts, it's essential to consider the application in which they will be used.

Different types of T-Slot Nuts are designed for use in different applications,

and selecting the wrong type can result in an unreliable connection.

2.Choose the right size

T-Slot Nuts are available in a variety of sizes,

and selecting the right size is essential for ensuring a secure connection.

Be sure to choose a nut that is compatible with the size of the T-slot in your aluminum profile.

3.Choose the right material

T-Slot Nuts are typically made from steel or stainless steel.

Selecting the right material is essential for ensuring that the nut is durable and corrosion-resistant.

4.Consider the load capacity

T-Slot Nuts have a specific load capacity,

and selecting a nut with a load capacity that is too low can result in a failed connection.

Be sure to choose a nut that is capable of handling the expected load.

In conclusion, T-Slot Nuts are an essential component in many manufacturing and construction projects.

Selecting the right type of T-Slot Nut is essential for ensuring a reliable and secure connection.

By considering the application, size, material, and load capacity,

you can select the right T-Slot Nut for your specific project.

At SAIVS, we rely on advanced manufacturing processes to ensure that our products meet industry

standards for strength and durability.We are committed to providing you with the most professional services.

If you need help,please contact us!

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

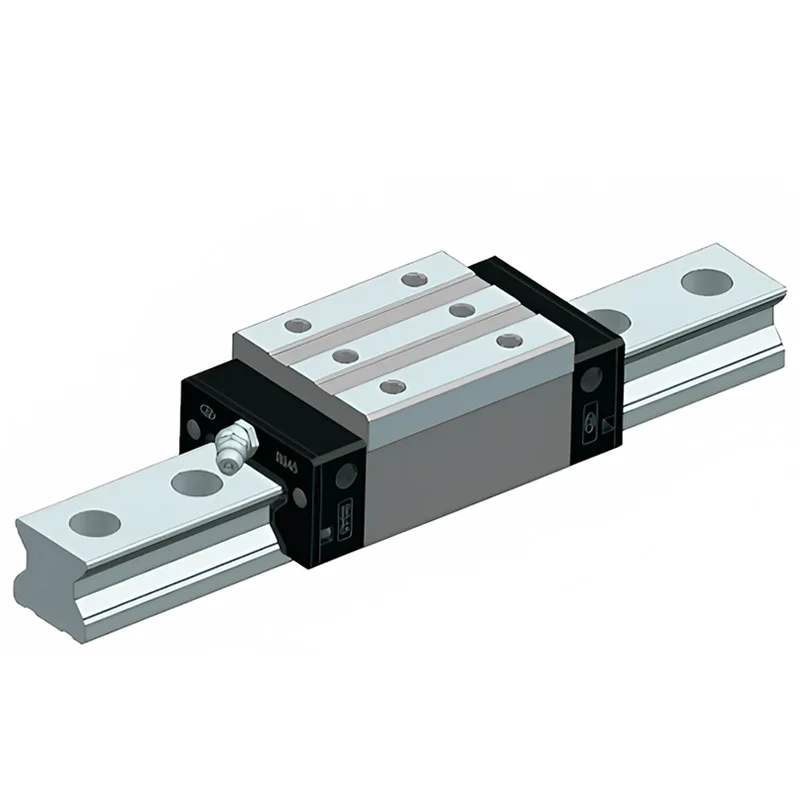

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS