How to Improve the Efficiency of Hydraulic Joint Bearings

Hydraulic Joint Bearings are crucial components in hydraulic systems,

providing necessary support and reducing friction between different parts.

They are widely used in industrial machinery, automotive applications, and other equipment.

However, over time, hydraulic joint bearings can wear out,

leading to decreased efficiency and eventual failure.

To ensure optimal hydraulic system performance,

it is important to maintain and improve the efficiency of hydraulic joint bearings.

1.Proper Lubrication

The most critical factor in improving hydraulic joint bearing efficiency is proper lubrication.

The lubricant acts as a barrier between the bearing surfaces, reducing friction and wear.

However, using the wrong type or quantity of lubricant

can actually increase friction and wear, reducing efficiency.

Therefore, it is essential to choose the right lubricant for the application

and ensure that the bearing is properly lubricated at all times.

The lubricant should be changed regularly to maintain its effectiveness.

2.Correct Alignment

Another important factor in improving hydraulic joint bearing efficiency is proper alignment.

Misalignment can cause increased wear and tear, leading to decreased efficiency and eventual failure.

Proper alignment can be achieved with precision machining and correct installation.

Regular checks should be made to ensure that the bearing

is correctly aligned and any necessary adjustments made promptly.

3.Adequate Clearance

To work efficiently, hydraulic joint bearings require adequate clearance,

which allows for free movement of the bearing components.

An inadequate clearance can cause increased friction, heat buildup, wear, and eventually failure.

Therefore, it is important to ensure that the bearing is installed

with the correct clearance according to the manufacturer's specifications.

4.Regular Maintenance

Regular maintenance is necessary to ensure the optimal efficiency and longevity of hydraulic joint bearings.

Regular inspection, cleaning, and lubricating are essential to prevent issues

and to detect any potential problems before they become severe.

Any issues identified should be rectified as soon as possible

to prevent further damage to the bearing and other components.

5.Proper Load Distribution

Imbalanced loads can cause uneven wear, leading to increased friction, heat buildup, and eventual failure.

Therefore, it is important to ensure that the load is distributed evenly across the bearing surface.

The correct bearing size and proper installation are critical to achieve proper load distribution.

6.Bearing Replacement

Despite regular maintenance, hydraulic joint bearings will eventually wear out and require replacement.

Before replacing the bearing, it is critical to identify the root cause of the problem

that led to the failure to prevent future failures.

Choosing the correct replacement bearing, installation,

and alignment is necessary to achieve optimal efficiency and prolonged lifespan.

In conclusion, improving the efficiency of hydraulic joint bearings is essential

to ensure the optimal performance of hydraulic systems.

By following these steps, you can minimize wear and tear, prevent unexpected downtime,

and avoid the costly repairs associated with hydraulic joint bearing failure.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

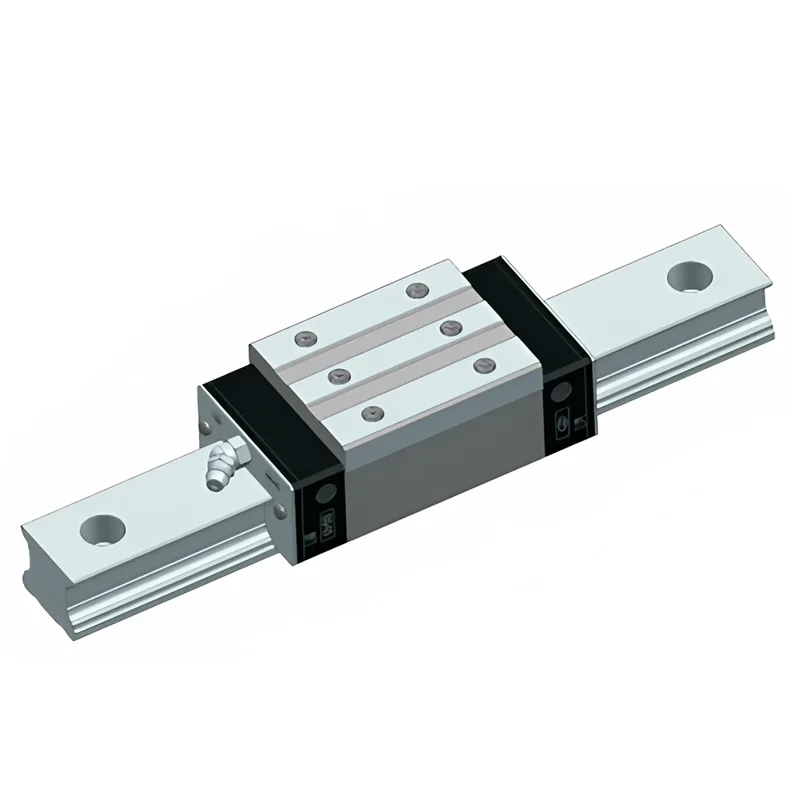

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS