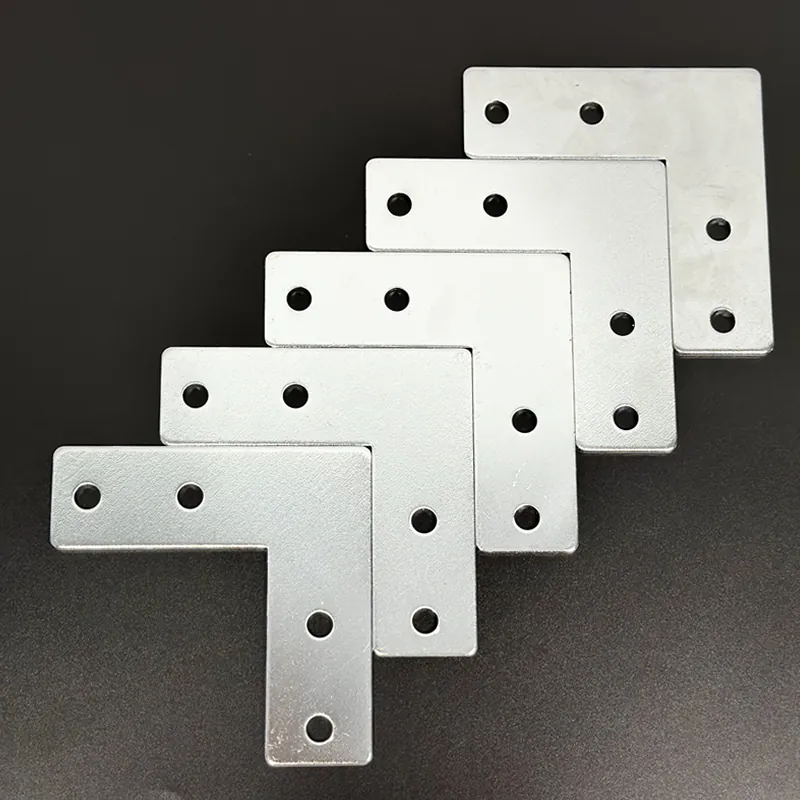

Are L-shaped brackets Suitable for Outdoor Applications

L-shaped brackets, also known as angle brackets, can be suitable for outdoor applications if they are made from materials that can withstand the environmental conditions they will be exposed to. Here are some key considerations for their suitability:

Material:

Stainless Steel: Highly resistant to rust and corrosion, making it ideal for outdoor use.

Galvanized Steel: Coated with a layer of zinc to prevent rust; good for outdoor use but may not be as durable as stainless steel.

Aluminum: Naturally resistant to corrosion, lightweight, and suitable for many outdoor applications.

Brass/Bronze: These materials are corrosion-resistant and can be used outdoors, though they are less common for heavy structural applications.

Coating:

Powder Coating: Provides an additional layer of protection against weathering and corrosion.

Paint: High-quality, weather-resistant paints can also protect metal brackets.

Environmental Factors:

Humidity and Rain: Materials with high corrosion resistance like stainless steel or properly galvanized steel are preferable.

Saltwater Exposure: In coastal areas, stainless steel is often the best choice due to its superior corrosion resistance.

Temperature Extremes: Some materials handle temperature fluctuations better than others. Metals like stainless steel and aluminum generally perform well.

Load Requirements:

Ensure the brackets can handle the structural loads expected in the outdoor environment, which might include wind, snow, or other forces.

For example, if you are installing an L-shaped bracket to support a shelf or a structure in a garden or on an exterior wall, choosing a stainless steel bracket would be a good idea for its durability and resistance to rust. If cost is a concern, galvanized steel can be a more economical choice, provided it is adequately protected from direct and prolonged exposure to moisture.

In summary, L-shaped brackets are suitable for outdoor applications if you select the right material and finish based on the specific environmental conditions they will face.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS