End Square Connectors for Aluminum Profiles

End square connectors, also known as square corner brackets or aluminum angle connectors, are essential components for constructing robust and versatile structures using aluminum profiles. These connectors play a crucial role in connecting aluminum profiles at right angles, providing rigidity and stability to the overall framework. Their versatility and ease of installation make them a popular choice for a wide range of applications, from DIY projects to industrial constructions.

Types of End Square Connectors

End square connectors come in various styles and sizes to accommodate different aluminum profile dimensions and application requirements. The most common types include:

Two-way connectors: These connectors allow two aluminum profiles to be joined at a 90-degree angle.

Three-way connectors: These connectors enable three aluminum profiles to be connected at a single point, forming a corner or intersection.

Four-way connectors: These connectors facilitate the connection of four aluminum profiles at a single point, creating a central junction.

Materials and Finishes

End square connectors are typically manufactured from high-quality aluminum alloys, such as 6061 or 6063, ensuring durability and strength. These alloys offer excellent corrosion resistance and can withstand demanding environments.

To enhance their appearance and protect against wear and tear, end square connectors are often subjected to various surface treatments, including:

Anodizing: This process creates a hard, protective oxide layer on the aluminum surface, enhancing its resistance to corrosion and scratches.

Powder coating: This method involves applying a layer of dry powder paint to the connector, providing a durable and aesthetically pleasing finish.

Natural aluminum: Connectors left in their natural aluminum state offer a raw, industrial look and are often preferred for applications where aesthetics are not a primary concern.

Applications of End Square Connectors

The versatility of end square connectors makes them suitable for a diverse range of applications, including:

Framing and structures: Connectors are widely used in constructing frames, racks, and other structures for various purposes, such as furniture, displays, and industrial workstations.

Machinery and equipment: Connectors are employed in building machinery components, enclosures, and safety guards.

Automotive and aerospace: Connectors find applications in constructing lightweight and durable components for vehicles and aircraft.

DIY projects: End square connectors are popular among hobbyists and DIY enthusiasts for creating shelves, organizers, and other home improvement projects.

Benefits of Using End Square Connectors

The use of end square connectors offers several advantages:

Ease of installation: Connectors are typically designed for simple and quick installation, often requiring minimal tools and expertise.

Versatility: The wide range of connector types and sizes caters to diverse applications and aluminum profile dimensions.

Strength and stability: Connectors provide rigid connections, ensuring the stability and integrity of the structure.

Clean appearance: Connectors contribute to a clean and professional look for the overall structure.

Cost-effectiveness: Connectors are a relatively inexpensive way to achieve strong and reliable connections.

Choosing the Right End Square Connectors

When selecting end square connectors, consider the following factors:

Profile size: Ensure the connector is compatible with the dimensions of the aluminum profiles being used.

Material and finish: Choose the material and finish that align with the application's requirements and aesthetic preferences.

Load requirements: Consider the weight and forces the connectors will need to support.

Installation method: Select connectors that suit the desired installation method, such as screw-on, bolt-on, or press-fit.

Conclusion

End square connectors are indispensable components for constructing robust, versatile, and aesthetically pleasing structures using aluminum profiles. Their ease of use, strength, and cost-effectiveness make them a popular choice for a wide range of applications. By carefully selecting the appropriate connectors based on the specific requirements of the project, users can ensure the integrity and longevity of their aluminum profile structures.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

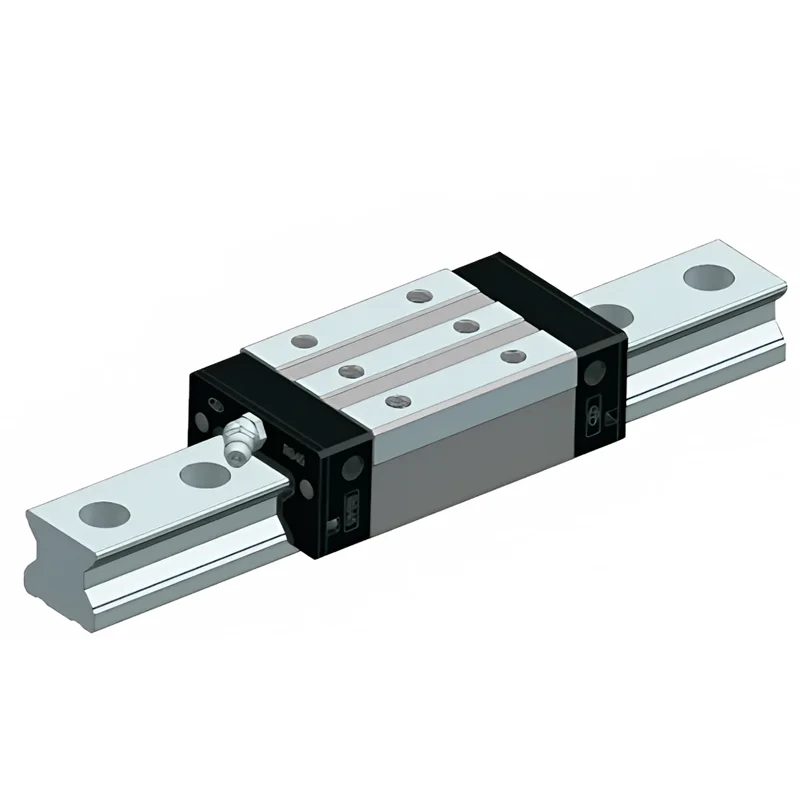

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

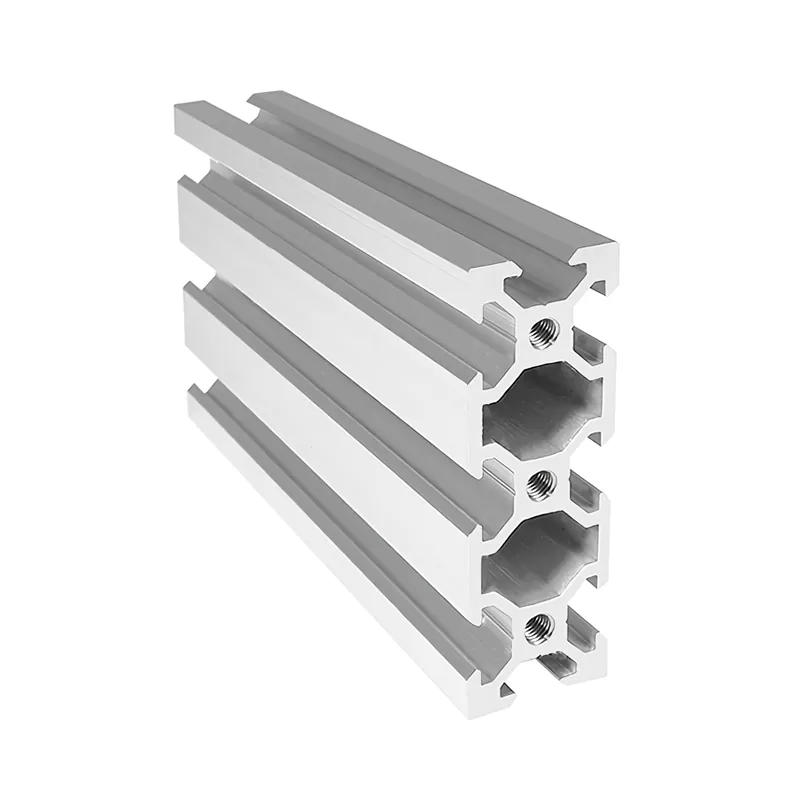

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS