Choosing the Right Leveling Casters

Leveling casters are versatile for ensuring stability and mobility in various applications. Here are some key factors to consider when selecting the right leveling casters:

Wheel Material

Leveling casters come with different wheel materials, such as nylon or polyurethane. Polyurethane wheels, typically with an aluminum core, offer durability and smooth rolling, while nylon wheels are known for their strength and resistance to wear.

Leveling Mechanism

Consider the type of leveling mechanism the casters employ. Most feature an anti-vibration leveling pad that can be adjusted to level the object they support. Please make sure the mechanism is easy to operate and provides reliable leveling.

Bearing vs. No Bearing

Some leveling casters incorporate ball bearings to reduce friction, enabling smoother movement. These bearings roll within a protected raceway, minimizing debris interference. Alternatively, traditional designs without bearings are also available.

Capacity

Ensure the leveling casters can safely support the weight of the objects they'll be rolling and moving. Check the listed capacity, which indicates the maximum weight the caster can handle without compromising performance or safety.

Wheel Size

Consider the diameter of the wheels when selecting leveling casters. Wheel sizes typically range from 42mm to 90mm in diameter. Choose a size suitable for your specific application and environment to ensure optimal performance.

Application

Evaluate the intended use and environment where the leveling casters will be deployed. Consider factors such as floor surface, temperature, and exposure to chemicals or moisture to select casters that can withstand the conditions.

Brand Reputation and Reviews

Research reputable brands are known for producing high-quality leveling casters. Read customer reviews and testimonials to gauge user satisfaction and performance in real-world applications.

By carefully considering these factors, you can choose leveling casters that meet your specific stability, mobility, and durability requirements.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

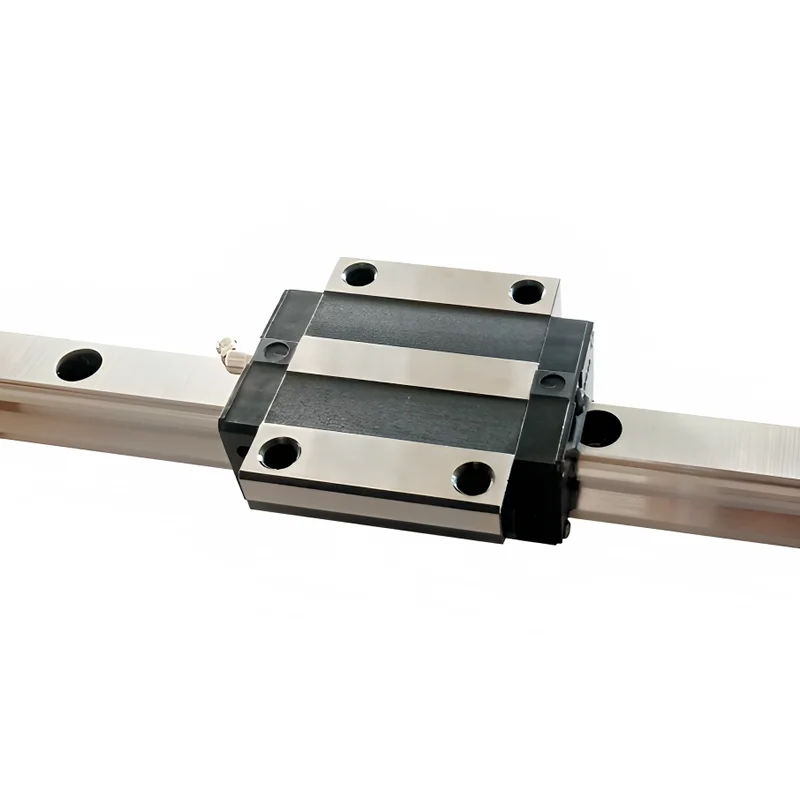

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS