Advancements in Ball Screw Technology for Next-Generation Humanoid Robots

Advancements in Ball Screw Technology for Next-Generation Humanoid Robots

Humanoid robots are rapidly evolving, with applications expanding into diverse fields such as healthcare, disaster response, and personal assistance.

As these robots become more sophisticated, the demand for high-performance components like ball screws continues to grow. Ball screws, which convert rotational motion into precise linear motion, are critical for enabling the complex movements and functionalities of humanoid robots.

This article explores the latest advancements in ball screw technology and their implications for the future of humanoid robotics.

1. Miniaturization and Lightweight Design

One of the most significant trends in ball screw technology is miniaturization.

As humanoid robots become more compact and agile, the need for smaller, lighter components has become paramount.

Traditional ball screws, while effective, often occupy significant space and add weight to the robot's structure.

Recent advancements in materials science and manufacturing techniques have led to the development of ultra-compact ball screws that maintain high performance while reducing size and weight.

For instance, the use of advanced alloys and composite materials has enabled the creation of ball screws with thinner screw shafts and smaller ball bearings, without compromising strength or durability. These lightweight designs are particularly beneficial for humanoid robots, as they reduce the overall energy consumption and improve mobility, allowing robots to perform tasks with greater efficiency and precision.

2. Enhanced Precision and Repeatability

Precision is a cornerstone of humanoid robot functionality.

Whether it's performing delicate surgical procedures or assembling intricate electronic components, the ability to execute precise movements is essential.

Modern ball screws are being engineered with tighter tolerances and improved surface finishes to achieve micron-level accuracy.

This is achieved through advanced machining processes, such as precision grinding and computer-controlled polishing, which ensure that the screw shaft and nut are perfectly aligned.

Additionally, innovations in ball recirculation systems have minimized backlash and improved repeatability.

Backlash, the slight movement that occurs when the direction of motion is reversed, can significantly impact the accuracy of a robot's movements.

By optimizing the design of the ball recirculation channels, manufacturers have reduced backlash to near-zero levels, enabling humanoid robots to perform highly repeatable tasks with exceptional consistency.

3. Increased Load Capacity and Durability

Humanoid robots are often required to handle heavy loads or operate in demanding environments.

To meet these challenges, ball screws are being designed with enhanced load-bearing capabilities.

This is achieved through the use of high-strength materials, such as hardened steel and ceramic balls, which can withstand higher stresses without deformation.

Furthermore, advancements in lubrication technology have extended the lifespan of ball screws by reducing wear and tear, even under continuous heavy loads.

Durability is another critical factor, especially for robots deployed in harsh environments, such as disaster zones or industrial settings.

Corrosion-resistant coatings and sealed designs protect ball screws from contaminants like dust, moisture, and chemicals, ensuring reliable performance over extended periods.

These improvements not only enhance the robot's operational lifespan but also reduce maintenance requirements, making humanoid robots more cost-effective and practical for real-world applications.

4. Integration with Smart Technologies

The integration of ball screws with smart technologies is another exciting development.

Modern ball screws are increasingly being equipped with sensors and embedded systems that provide real-time feedback on performance metrics such as position, speed, and load.

This data can be used to optimize the robot's movements, detect potential issues before they escalate, and enable predictive maintenance.

For example, a humanoid robot equipped with sensor-enhanced ball screws can adjust its grip strength based on the weight and fragility of an object, or modify its gait to navigate uneven terrain.

These capabilities are made possible by the seamless integration of ball screws with the robot's control systems, paving the way for more autonomous and adaptive robots.

5. Future Prospects

As humanoid robots continue to advance, the role of ball screws will become even more critical.

Future developments are likely to focus on further enhancing precision, durability, and integration with emerging technologies such as artificial intelligence and machine learning. Researchers are also exploring the use of alternative materials, such as graphene and carbon nanotubes, to create ball screws that are not only stronger and lighter but also capable of self-lubrication and self-healing.

In conclusion, ball screws are indispensable to the functionality and performance of humanoid robots.

The ongoing advancements in ball screw technology are driving the evolution of these robots, enabling them to perform increasingly complex tasks with greater efficiency and reliability.

As we move toward a future where humanoid robots play a more prominent role in society, the continued innovation of ball screws will be essential in bringing these remarkable machines to their full potential.

How to avoid roller bearing failures

How to avoid roller bearing failures

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

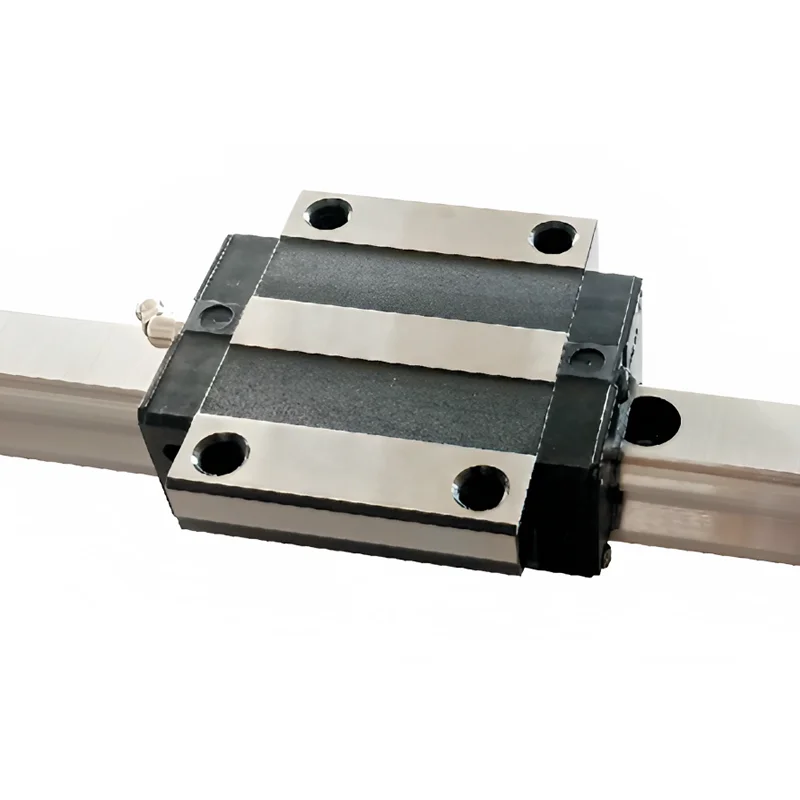

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd