Why Are Hex Socket Screws So Popular

Hexagon socket head screws are a favored choice for many due to their unique design and performance benefits. Let's explore why hexagon socket head cap screws are designed in a hexagonal shape and its benefits.

Why the hexagonal design?

The hexagonal design of hexagon socket head cap screws makes them easier to twist. Hexagonal screws can be graphically restored with just 60° of rotation, making them particularly suitable for installations in tight spaces, as long as the spanner can be rotated 60 degrees to tighten the screw. This design is the result of a compromise between the screwing angle and the length of the sides. If the quadrilateral design is used, despite the increase in side length, it needs to be rotated 90 degrees to complete the graphic reduction, making it difficult to operate in small spaces. And if an octagonal or more polygonal design is used, despite the smaller rotation angle, the stress surface is reduced and the screws tend to wear out or round off. In addition, designs with an odd number of sides are not suitable for efficient force transmission because the two sides of the spanner are not parallel and the force is uneven.

Hardness and performance ratings of hexagon socket head cap screws

Hexagon socket head cap screws are classified into several grades based on hardness and performance, with common grades 4.8, 8.8, 10.9, and 12.9. The hardness grade of a screw reflects its tensile and yield strength. For example, Grade 4.8 screws have a nominal tensile strength of 400 MPa and a yield strength of 240 MPa, while Grade 10.9 screws have a tensile strength of up to 1,000 MPa and a yield strength of 900 MPa. The higher the grade, the higher the strength and durability of the screws, which make them suitable for applications subjected to greater loads.

High-strength socket head cap screws (grade 8.8 and above) are heat-treated and made from low-carbon alloy steel or medium-carbon steel and are widely used in industrial structures. High-strength screws such as Grade 8.8, 10.9, and 12.9 are commonly used in the market and have outstanding performance in assembly and maintenance.

Advantages of using hexagon socket head cap screws

Can withstand greater load: hexagonal design of the hexagonal socket head cap screws has six force surfaces, compared with the two-sided force of the word or Phillips screws, it can withstand greater force and is not easy to damage.

Can be countersunk: Hexagon socket head cap screws can be sunk inside the workpiece to keep the surface of the workpiece flat and beautiful, which is especially important for some products with high design requirements.

Easy to install: Compared with hexagon socket head cap screws, hexagon socket head cap screws are more suitable for narrow assembly environments, and easier to install and maintain.

Not easy to disassemble: Hexagon socket head cap screws require a special spanner to disassemble, which increases the difficulty of disassembly, prevents unauthorized unauthorized disassembly, and ensures equipment safety.

These features make hexagon socket head cap screws popular in industrial and daily applications, especially in the need for strength and durability of both occasions with excellent performance.

How to avoid roller bearing failures

How to avoid roller bearing failures

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

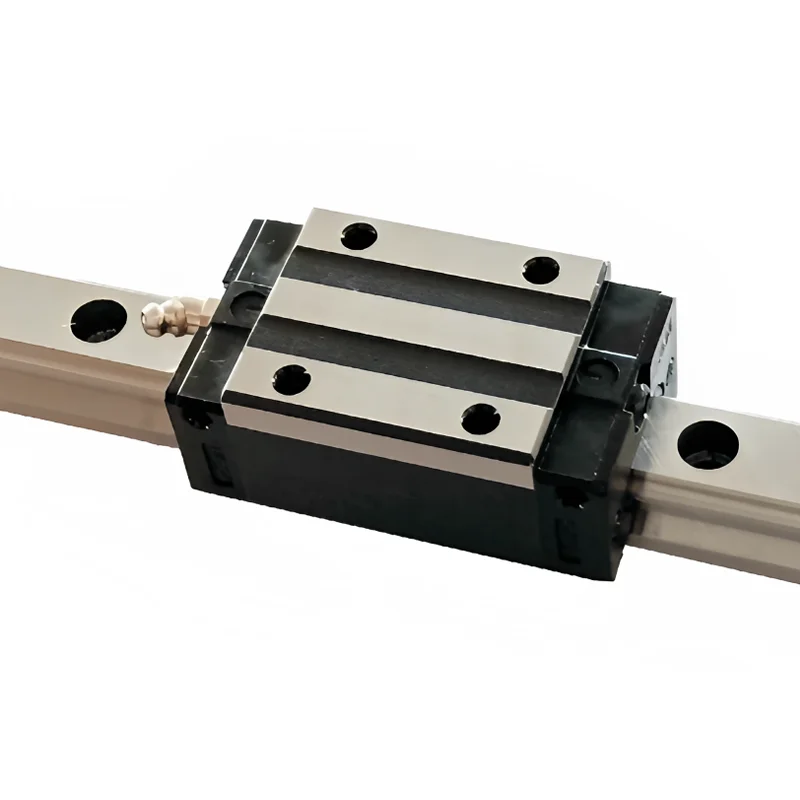

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd