Causes of Loose Bolts in Industrial Aluminum Profiles and Solutions

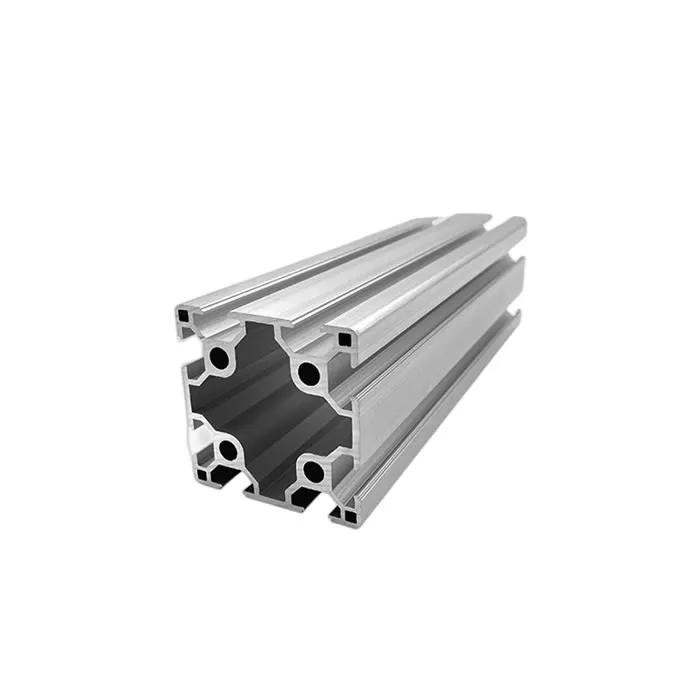

Aluminum profiles are widely used in industrial applications due to their lightweight and high strength. However, loose bolts are a common issue that can lead to structural instability and equipment failure. Understanding the causes of loosening and the solutions is essential for ensuring the safety and reliability of equipment.

Causes of Loose Bolts

Vibration Machinery generates vibrations during operation, which can gradually loosen bolts, especially in high-frequency vibration environments.

Thermal Expansion and Contraction Temperature fluctuations can cause both aluminum profiles and bolts to expand and contract. Frequent changes in temperature may reduce the clamping force of the bolts, leading to loosening.

Improper Installation If bolts are not tightened to the specified torque during installation or if inappropriate tools are used, the effectiveness of the fastening may be compromised.

Material Fatigue Prolonged loads and usage can lead to material fatigue in the bolts and connecting components, gradually diminishing their holding capacity.

Corrosion In humid or corrosive environments, bolts may suffer from corrosion, weakening their strength and fastening effectiveness.

Regular Inspections Regularly check the tightness of all bolts, especially in high-vibration environments, to promptly identify and address any loosening issues.

Proper Installation Methods When installing bolts, use a torque wrench to ensure they are tightened to the manufacturer's recommended torque, ensuring a secure connection.

Use Locking Materials Utilize locking washers, lock nuts, or thread locking adhesives at bolt connections to effectively reduce the risk of loosening.

Vibration Reduction For equipment with significant vibrations, consider using vibration-damping devices to minimize the impact on the bolts during operation.

Improve Working Environment Avoid operating bolts in humid or corrosive environments whenever possible. If necessary, apply anti-corrosion treatments to extend their lifespan.

Conclusion

Loose bolts in aluminum profiles are a significant concern that can impact the stability and safety of equipment. By implementing regular inspections, ensuring proper installation, using locking materials, and improving the working environment, the risk of bolt loosening can be effectively minimized, ensuring the long-term stable operation of machinery.

How to avoid roller bearing failures

How to avoid roller bearing failures

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

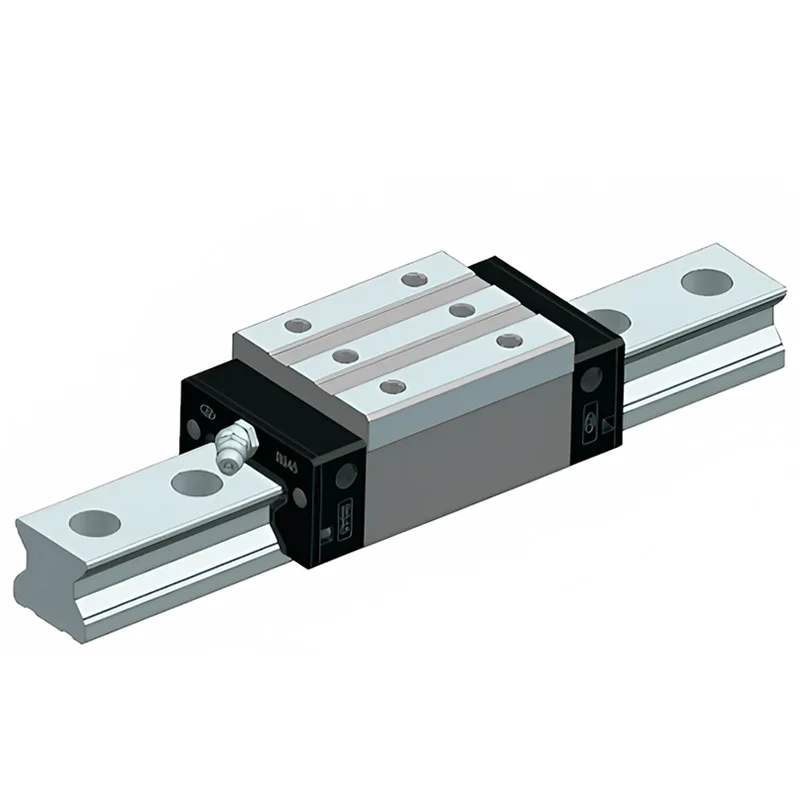

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd