What are needle roller bearings used for

A needle roller bearing is a specialized type of roller bearing

that is designed to reduce the friction of a rotating surface.

These bearings use elongated cylindrical rollers that resemble needles,

and they are typically at least four times longer than their diameter.

This is in contrast to ordinary roller bearings,

whose rollers are only slightly longer than their diameter.

One of the main advantages of needle bearings is that they

offer a greater surface area in contact with the races,

which allows them to support greater loads compared

to ball bearings and ordinary roller bearings.

In addition, these bearings are also thinner,

which means they require less clearance between the axle and the surrounding structure.

Due to their unique design and superior performance,

Needle Roller Bearings are heavily used in the automotive industry.

They are used in components such as rocker arm pivots, pumps, compressors, and transmissions.

For example, the drive shaft of a rear-wheel drive vehicle typically contains

at least eight needle bearings (four in each U joint),

and even more if it operates on steep slopes or is particularly long.

Apart from the automotive industry, needle roller bearings are also

extensively used in industrial machinery and equipment.

Applications include printing presses, textile machinery, and food processing equipment.

In essence, needle roller bearings are utilized in many different

types of machinery and provide reliable rotational motion with reduced friction.

How to avoid roller bearing failures

How to avoid roller bearing failures

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

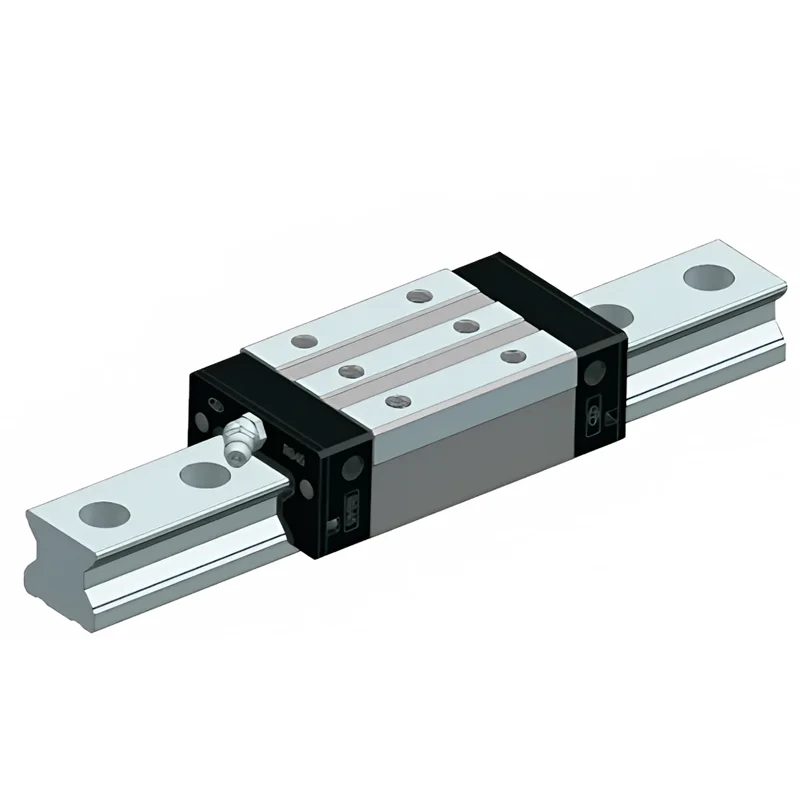

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

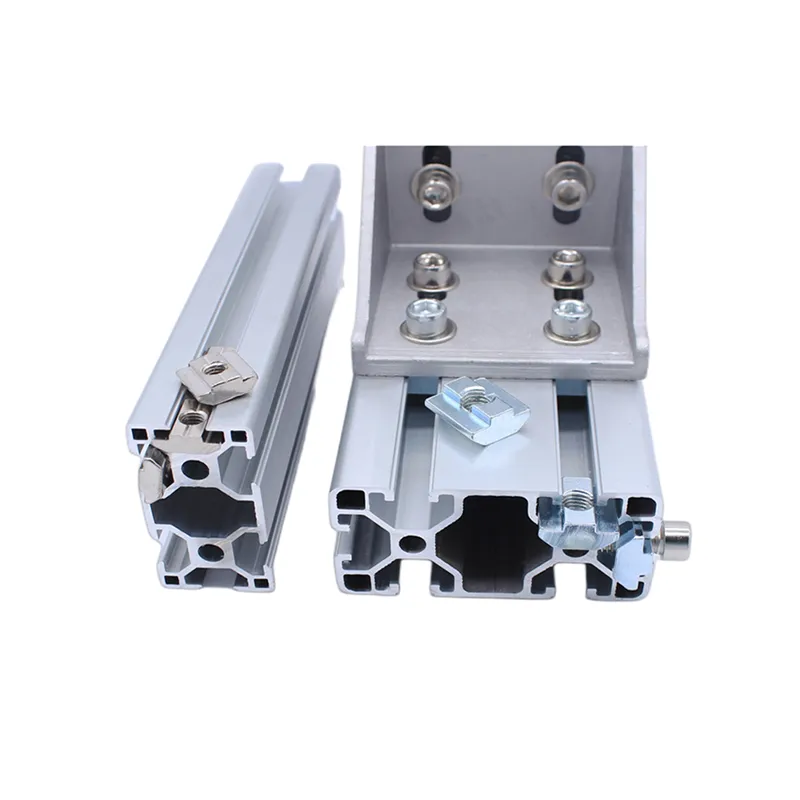

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd