About Needle Roller Bearings

The roller needle roller bearing is composed of a bolt

as the inner raceway of the roller set and a thick-walled outer ring.

The shoulder of the bolt shaft and the end face retaining ring pressed

on the bolt form the guide surface of the outer ring along the two side directions.

When the curved roller moves on the flat raceway or the cam disc,

the internal stress of the roller increases due to the elastic deformation of the outer ring.

Therefore, the rated load applied to this working situation is selected as the column of the curve roller.

Structure

| KR | Curved rollers guided axially by ribs and retaining rings |

| KR…PP | Curved rollers with seals |

| KRE | Curved rollers with eccentric sleeve |

| KRE…PP | Curved roller with eccentric sleeve and sealing ring |

| KRV | Curved rollers guided axially by ribs and rings, full needle |

| KRV…PP | Curved rollers with seals |

| KRVE | Curved rollers with eccentric sleeve |

| KRVE…PP | Curved roller with eccentric sleeve and sealing ring |

| NUKR | Backing track rollers with axial guidance of the rolling elements, full complement type |

| NUKRE | Curved rollers with eccentric sleeve |

Tolerance

The dimensional tolerance and rotation accuracy of standard bearing outer rings are usually PO level,

but it is not suitable for the outer surface of the arc,

the tolerance is mm, and the bolt diameter tolerance is h7.

Use and installation

When installing the curved roller, attention must be paid to the fit between the bolt and the hole,

as far as possible without gaps, and the recommended tolerance for the fit hole.

The belt is H7, the matching hole on the shaft must have a small chamfer to obtain the best bearing surface,

and the fastening nut must have anti-loosening measures.

Avoid hammering the ribs of the bolts during installation.

The groove on the end face of the bolt is used to fix the roller or adjust the position

of the eccentric sleeve with a suitable tool when tightening the nut.

The oil hole on the bolt raceway should be located in the non-load area as much as possible.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

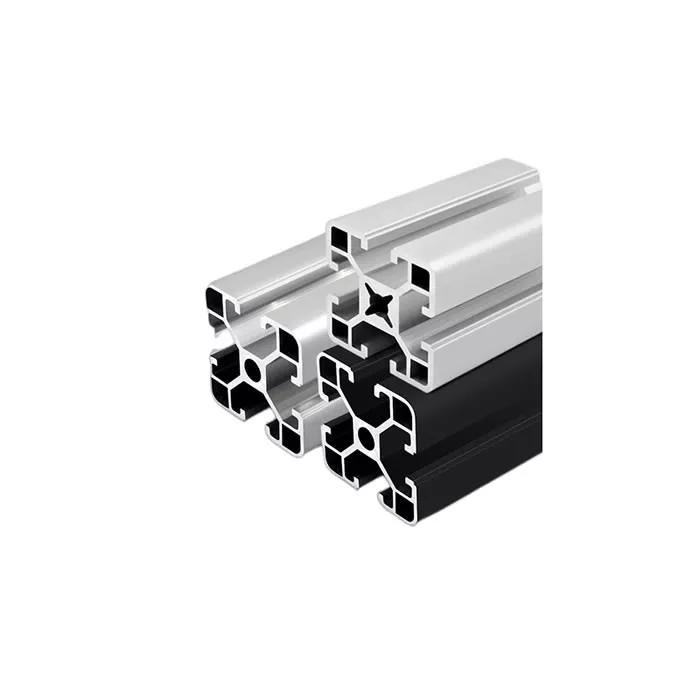

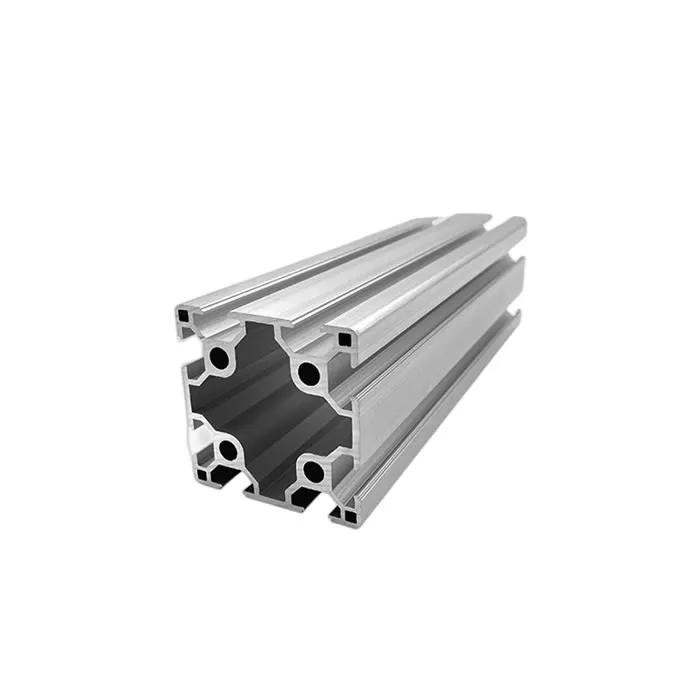

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS