What is plain shaft

Plain shafts are mechanical components responsible for propelling movement,

either sliding movement or rotational, between two parts of a machine.

Their main purpose is to prevent wear and tear in the machine's point of support,

which could occur if the two points were to roll directly on themselves or the structure.

Plain bearings consist of two parts: a fixed part that supports loads (support),

and a surface that gets worn when in contact with the moving elements.

To minimize friction losses in the shaft, low-friction materials are generally used in pairs,

or a lubricant like oil or compressed air is added between the parts.

Graphite or Teflon may be used as solid lubricants.

Types of bearings

The shaft to use depends on the Kind of contact between the two parts

and the bearings to be used and vice versa.

Find below some bearings to be used:

1.Friction bearing

They are also known as solid bearing, bushes, and friction shafts,

and they generally have a cylindrical shape.

In addition, they have no moving parts.

2.Hydrostatic bearings

The lubricant is fed by an external pump.

The main disadvantages are that a failure of

the lubricant supply compromises the installation and their high costs.

3.Hydrodynamic bearings

The hydrodynamic shafts do not require external injection of lubricants,

however, it's the moving parts that produce a hydrodynamic effect

that allows the oil to lubricate the parts in contact.

These bearings do their work on their own

and they don't require an external supply of pressurized oil.

Its use is essential for machines with high starting torque.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

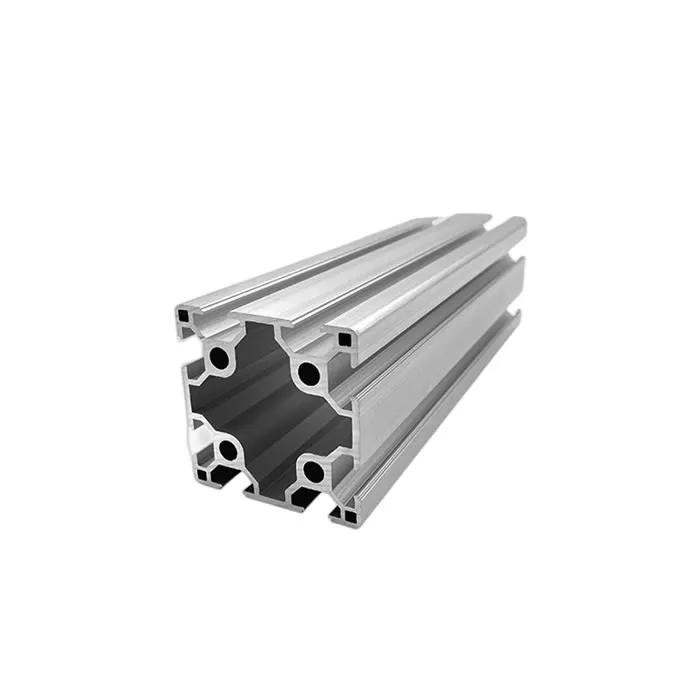

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS