Precautions for choosing LM Plain shaft special standard shaft

For Linear Bearings, since steel balls move directly on the surface of the shaft,

attention should be paid to its hardness, surface thickness and dimensional accuracy when selecting.

Since the surface hardness of the shaft has a great influence on the life,

please pay attention to the quality of the manufacturing material and the heat treatment method.

Material

Case-hardened materials suitable for high-frequency quenching manufacturing

GCr15 high carbon chromium bearing steel

Sk36 carbon tool steel

S55C carbon steel for mechanical machinery

etc. generally use the above materials.

In addition, corrosion-resistant martensitic stainless steel 9GCr18Mo/440C is also used in special cases

The surface hardness is above HRC58 (HV653),

and the depth of the hardened buckle depends on the size of the linear bearing,

but it is generally recommended to use about 2mm.

Surface Roughness

In order to make it roll smoothly, please process it below 1.6S.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

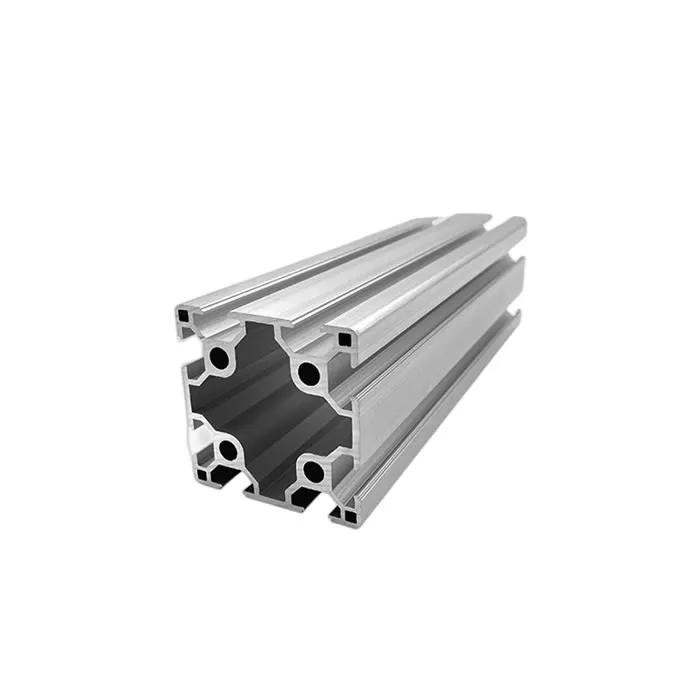

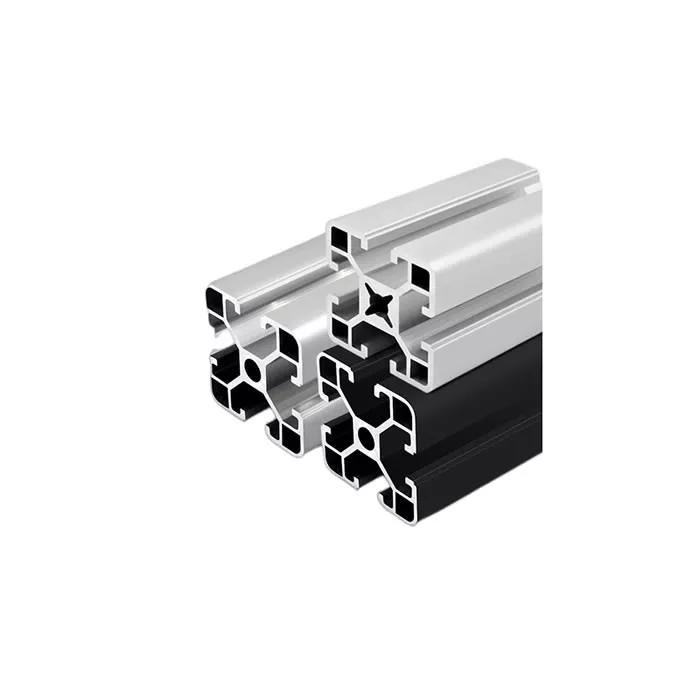

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS