The hidden side of needle roller bearings

There are many types of bearings, the most common being ball bearings,

or tapered roller bearings, cylindrical or spherical roller bearings.

Their design meets specific technical requirements to adapt to particular use.

Among them, less known, is the needle roller bearing,

which is nevertheless essential in certain applications

where the requirements in terms of reliability and durability are high.

What's special about it?

Needle Roller Bearings are a type of rolling element bearing

that gets its name from the unique shape of its rollers.

The rollers are shaped like needles, with diameters equal to or less than 5mm

and lengths at least three times greater than their diameter.

These steel needles can have either round or flat tips

and are mounted in a steel or molded polyamide cage,

providing a contact surface that is adept at supporting very heavy loads.

The compact assembly of needle roller bearings makes them a popular choice

when looking for a balance between performance, size and weight.

In fact, they are capable of withstanding 2 to 8 times more load

than ball bearings or cylindrical roller bearings of the same shaft diameter,

all while taking up less space.

In summary, needle roller bearings are a robust and highly efficient

bearing solution that excel in situations where space is at a premium.

Their compact design, high load capacity, and versatile applications make them

a go-to choice for engineers looking to optimize their designs.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

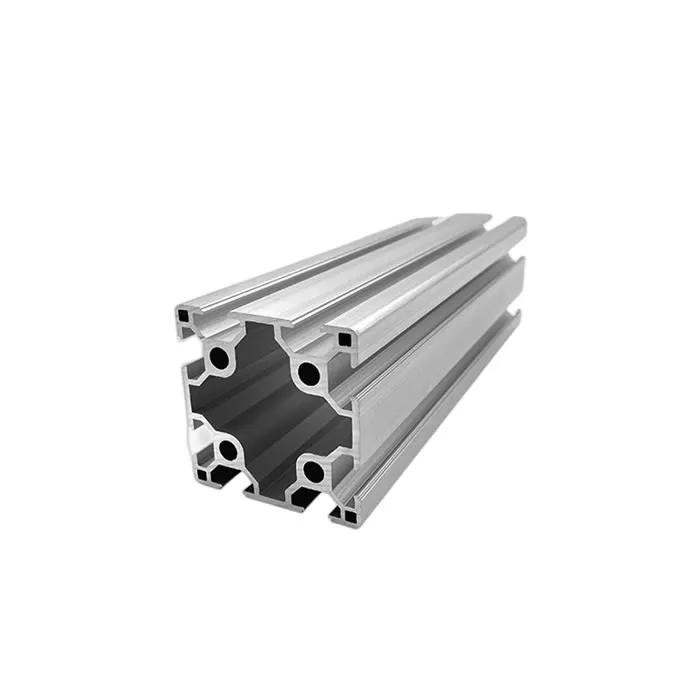

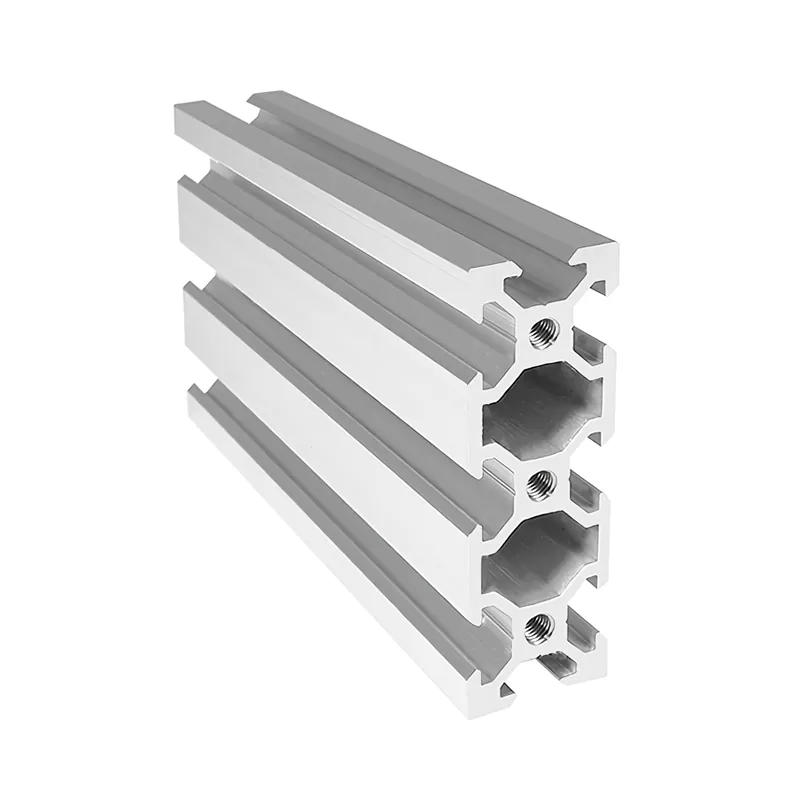

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS