Capability and Choice of Radial Spherical Plain Bearings

Mounting

To facilitate mounting, the ends of pins or shafts

and the edges of housingbores should have a lead chamfer of 10 to 20°.

The bearings can be moreeasily pushed into position and there is little

risk of damage to the matingsurfaces being caused by skewing of the bearing.

When mounting spherical plain bearing with a fractured or two-part outerring,

it is essential that the joint should be positioned at 90 to the main loaddirection,

otherwise the service life will be shortened, particularly underheavy load.

Lubrlcatlon

For spherical plain bearings requiring maintenance which are of thesteel-on-steel type,

the purpose of the lubrication is primarily to reducewear, reduce friction and corrosion.

The frequency of relubrication of thebearing during its operation will appreciably extend the service life.

For steel-on-PTFE fabric spherical plain bearings,

there is a transfer ofPTFE from fabric to the opposing steel surface of the inner ring.

Anylubrication of the sliding contact surfaces would disturb this transfer andshorten bearing life.

Therefore' lubrication of these bearings is notadvisable.

For steel-on-PTFE composite material spherical plain bearings, as arule, it must not be lubricated.

When operating conditions are such thatenhanced sealing and protection against corrosion are required,

it is recommended that the bearing ar the space surrounding the bearing is filledwith lithium base grease.

Accuracy

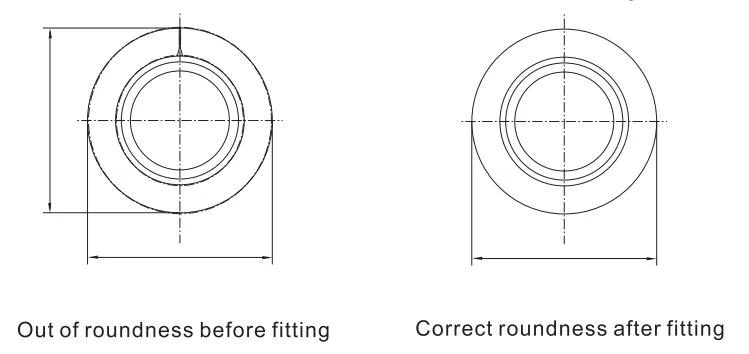

The tolerances apply to outer ring without surface treatment and splitting.

The outer rings become slightly out of round due to splitting.

Theroundness of the outer ring is restored once

it is fitted in a housing boreproduced in accordance with the specifications,

Measurements taken of the outside diameter of the unfired bearingcannot

be used as the original actual values for the outside diameter.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS