Design and application features of spherical plain bearings

Load Rating

The values of load rating are always dependent on the definition used.

Itis therefore not always possible to make direct

comparisons with load ratingspublished by other manufactures.

The static load rating is used when spherical plain bearings stand

stillunder load(or make occasional alignment movements) and it should also beconsidered

when dynamically loaded bearings are subjected to heavy shockloads.

The static load rating represents the load which can be taken up

by aspherical plain bearing when static contact stress of bearing

contact surfacereaches the material stress limit.

It is valid at room temperature and it ispresupposed that

the surrounding components prevent deformation of thebearing.

At higher temperature, the static load rating must be multiplied by atemperature factor,

depend on the sliding contact surface combination.

Thetemperature factor are the same as for dynamically stressed bearing.

It isalso necessary to take into consideration the permissible temperature

rangefor the various sliding contact surface combinations.

For rod ends, it is thestrength of the rod end housing under stationary load which is considered.

The rod end static load ratings give a safety factor of 1.2

timesthe tensile strength of the rod end housing material.

Service Life

The service life of a spherical plain beading operated under mixed or dryfriction

conditions is determined by the increase in bearing clearance orbearing friction

caused by progressive wear of the sliding surfaces,

plasticdeformation of the sliding material or fatigue of the sliding surface.

Depending on the application, the permissible wear or permissibleincrease in friction will be different.

This means that under the sameoperating conditions

the service life which can be obtained in practice will bedifferent.

The service life of a spherical plain bearing is the number of oscillatingmovements,

or the number of operating hours, which the bearing will servicebefore a defined

increase in bearing clearance or a defined increase infriction is reached.

The effective service life is that life which will be attained by a given

spherical plain bearing under actual operating conditions.

It is determined bythe magnitude and type of load, but also by several other factors,

such ascontamination, corrosion, high-frequency load and movement cycles, shock etc.

Some of these factors are impossible to determine or can only bedetermined with difficulty.

Bearing Contact Pressure

If an adequate operating life is to be achieved,

a basic requirement is thatthe bearing contact pressure is compatible with the operating conditions.

Thebearing contact pressure identifies the surface pressure occurring in thebearing

and is a decisive criterion for the assessment of a spherical plainbearing in each individual application.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

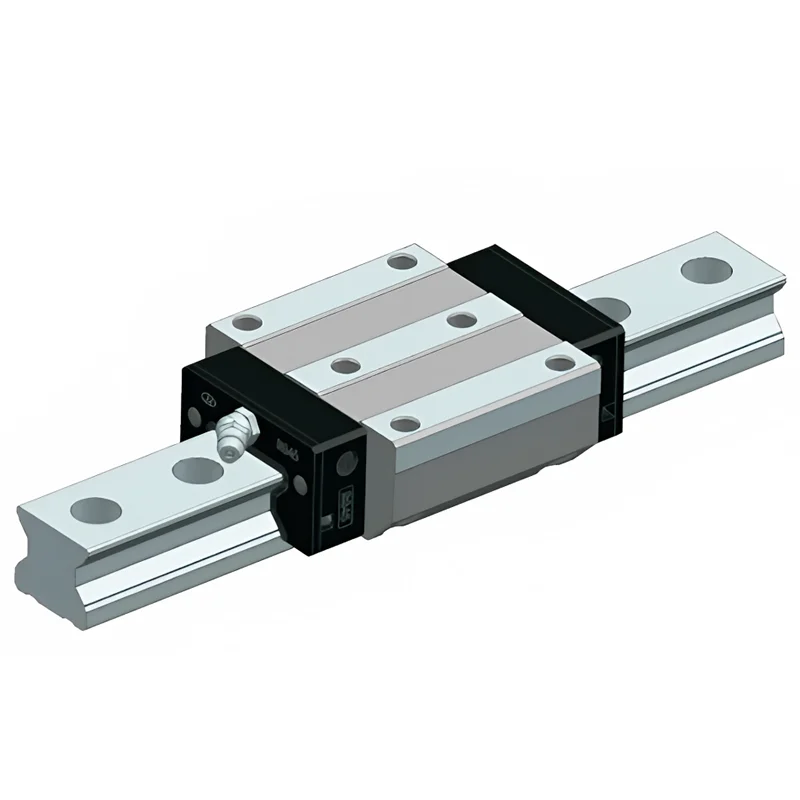

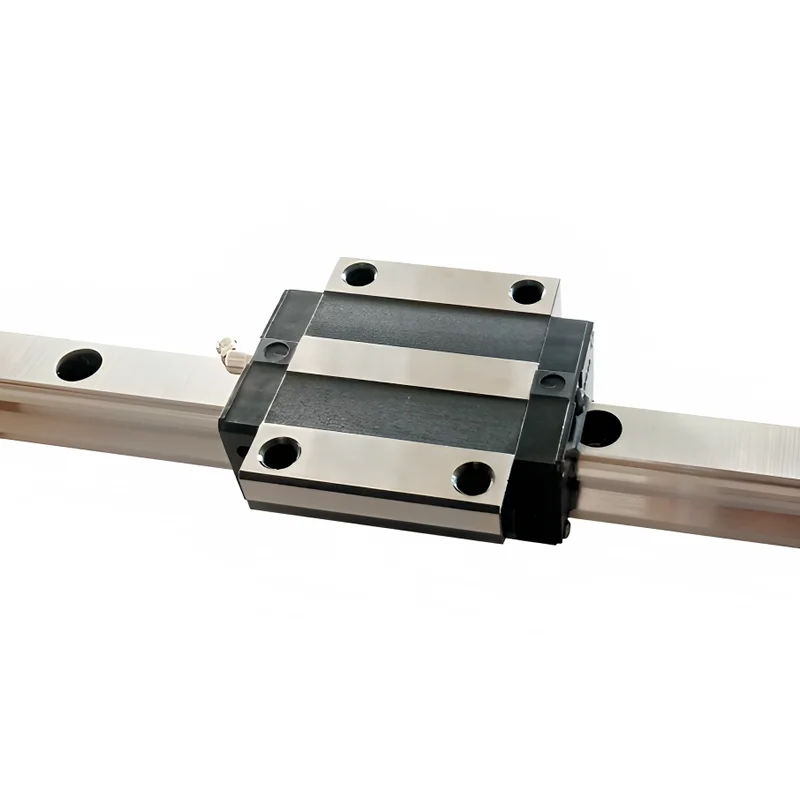

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS