Usage And Characteristics Of Radial Joint Bearings

Service Life

A spherical plain bearing's service life in mixed or dry friction conditions

is determined by the progressive wear of its sliding surfaces, plastic deformation of the sliding material,

or fatigue of the sliding surface, causing an increase in bearing clearance or friction.

The permissible wear or increase in friction varies depending on the application,

resulting in different achievable service lives under the same operating conditions.

The service life of a spherical plain bearing is stated as the number of oscillating movements

or operating hours before defined increases in bearing clearance or friction occur.

The effective service life, which is what a specific spherical plain bearing can achieve

under actual operating conditions, is determined by various factors, including load type and magnitude, contamination,

corrosion, high-frequency loads, and motion cycles and shocks.

Some of these factors can be difficult or impossible to determine.

Bearing Contact Pressure

To achieve adequate operating life, compatible bearing contact pressure with operating

conditions is a fundamental requirement. Bearing contact pressure represents the surface pressure generated

within the bearing and is a decisive criterion in evaluating a spherical plain bearing for each individual application.

Mounting

Lead chamfers of 10-20 degrees should be used on the ends of pins or shafts

and the edges of housing bores to make mounting of the bearings easier and reduce skewing risks that can damage mating surfaces.

When mounting spherical plain bearings with a fractured or two-part outer ring, ensure the joint

is positioned at 90 degrees to the primary load direction; otherwise, the service life will be shortened, particularly under heavy loads.

Lubrication

For steel-on-steel type spherical plain bearings requiring maintenance,

lubrication is primarily used to reduce wear, friction, and corrosion.

The frequency of relubrication during bearing operation can extend the bearing's service life significantly.

For steel-on-PTFE fabric spherical plain bearings, PTFE transfers from the fabric to the steel surface of the inner ring.

Any lubrication of the sliding contact surfaces would disrupt this transfer,

and it would shorten the bearing's life. Thus, lubricating these bearings is not recommended.

For steel-on-PTFE composite material spherical plain bearings, lubrication is typically not required.

Lithium-based grease is recommended for enhanced sealing, protection against corrosion, and improved strength.

Accuracy

The tolerances apply to outer rings without surface treatment and splitting.

Splitting causes slight out-of-roundness in outer rings,

which is restored by fitting them in a housing bore produced in accordance with the specifications.

Measurements taken of the outside diameter of unfitted bearings cannot be used as the original actual values for the outside diameter.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

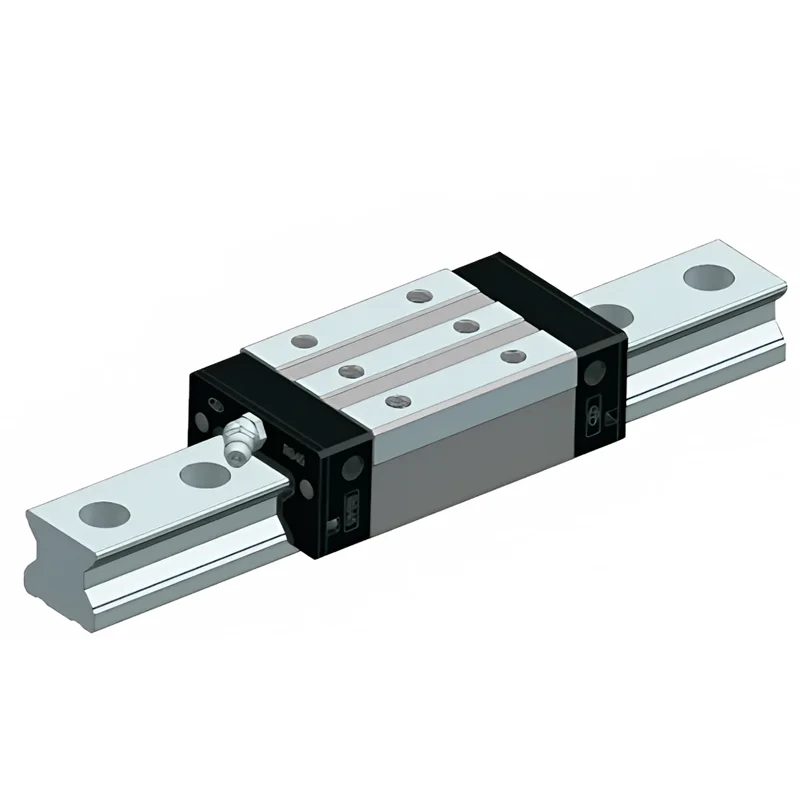

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS