Characteristics of radial joint bearings

Radial spherical plain bearings have an inner ring with a sphereconvex outside surface

and an outer ring with a correspondingly sphere butconcave inside surface.

Their design makes them particularly suitable forbearing arrangements where alignment movements

between shaft andhousing have to be accommodated, or where oscillating or recurrent tilting orslewing movements

must be permitted at relatively slow sliding speeds radial spherical plain bearings

are available with different sliding contactsurface combinations' i.e. the sliding surfaces of inner

and outer ringsare made from different materials. There are two main groups sphericalplain bearings

requiring maintenance(steel-on-steel) and maintenance-freespherical plain bearings.

Radial soherical plain bearings requiring maintenance(steel-on-steel) have hardened sliding contact surface on both rings.

The surfacesare treated with molybdenum disulphide and phosphate.

It has characteristics of wear-resistance and wear-corrosion. Bearings

with thissliding contact surface combination require regular relubrcation.

The highstrength of the sliding contact surfaces makes these bearings especiallysuitable for bearing srrangements

where heavy loads of alternating direction,shock loads or heavy static loads have to be accommodated.

maintenance-free spherical plain bearings sliding contact surfaceshave three groups steel-on-PTFE composite material,

steel-on-PTFE fabricand steel-on-copper alloy. Dynamic load support capability of steel-on-PTFEfabric spherical plain bearings

is higher that of steel-on-PTFE fabricspherical plain bearings is higher than that of stee-on-PTFE compositematerial.

They have very low friction and can be operated without

maintenance. They are used for applications where long bearing lives arerequired without maintenance, or where operating conditions,

such asinadequate lubrication or the absence of lubrication make the use of steel-on-steel bearing inadvisable.

Design characteristics

Radial spherical plain bearings requiring maintenance(steel-on-steel) are made of carbon chromium steel

and are hardened and phosphatedexcept for series GEBK..S,COM…,GEBJ…S and GEK…XS-2RS.

The innerand outer ring sliding contact surface are treated with molybdenum

disulphide.The outer ring is fractured so that it can be sprung open when theinner ring is inerted.

Outer and inner ring of CEK…XS-2RS are made ofcarbon chromium steel and are hardened.

Outer rings of GE…XS/K andGEK…XS-2RS, held together by retaining rings. To facilitate efficient

lubrication, all bearings have an annular groove and lubrication holes in eachring except those of the E design.

Bearings of the 2RS design are fitted withnylon seals or rubbings seals of polyester elastomer at both sides.

Outer ringof series COM… and GEBJ…S are made of carbon steel, pressed around theinner ring;

Inner ring of carbon chromium steel, hardened, slidingsurface treated with chromium plating.

Outer rings of series GE…C,GEG…C,COM…T and GEBJ..C are made ofcarbon steel,

pressed around the inner ring,with sliding surface of PTFEcomposite material; Inner rings of carbon chromium steel, hardened,

Outer rings of series GE…C,GEG…C,COM…T and GEBJ..C are made of carbon steel,

pressed around the inner ring,with sliding surface of PTFEcomposite material;

Inner rings of carbon chromium steel, hardened,silding surface treated with chromium plating.

Outer rings of series GE…ET-2RS,GEG…ET-2RS and GEZ…ET-2RS are made of carbon chromiumsteel,

fractured, hardened and phosphated, with sliding surface treated withchromium plating the 2RS design with two seals at both sides.

Outer rings ofseries GE…ET/X and GE…ET-2RS/X are made of stainless steel,

fractured,with sliding surface of PTFE fabric; Inner rings of stainless steel,

hardened, the 2RS design with two seals at both sides. Outer rings ofseries GE..XT/X and GE…XT-2RS/X are made of stainless steel,

axiallysplit twice, held together by retaining rings, with sliding surface of PTFEfabric; Inner rings of stainless steel, hardened,

the 2RS design with twoseals at both sides. Outer rings of series GE…XF/Q,GEC..XF/Q and

GEH..XEF..XF/Q are made of carbon chromium steel, axially split twice, heldtogether by retaining rings, hardened and phosphated,

sliding surfacetreated with chromium plating; Inner rings of copper alloy, with slidingsutface of solid lubricant.

Outer ring of series GEH…HE/Q is made ofcarbon steel, radially split twice, held together by screws, phosphated,

sliding surface treated with chromium plating; Inner ring of copper alloy,

with sliding surface of solid lubricant make the use of steel-on-steel bearing inadvisable.

How to avoid roller bearing failures

How to avoid roller bearing failures

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

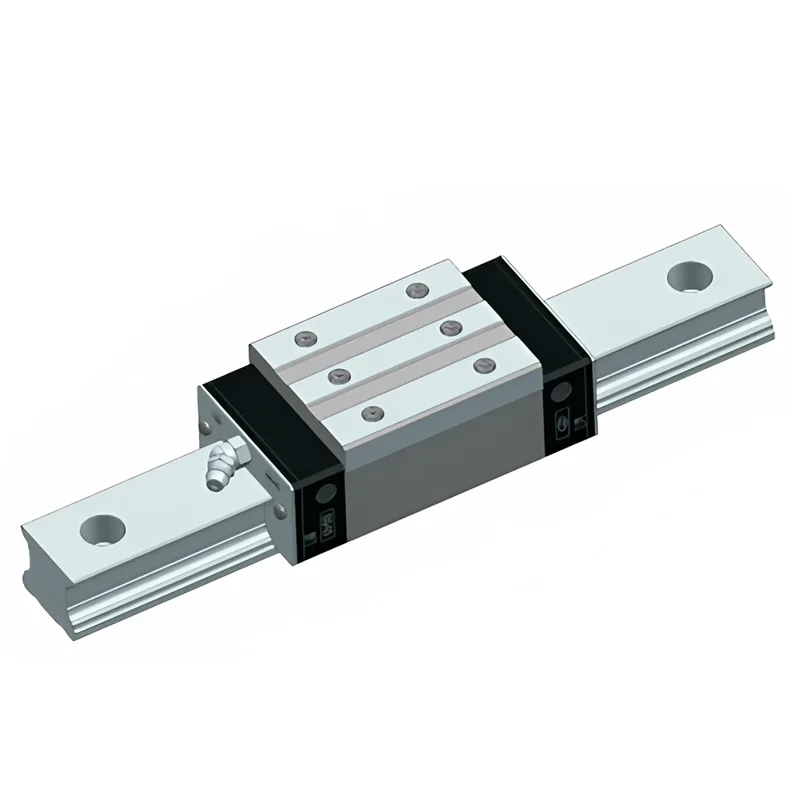

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd