Reusability of aluminum profile screws

The reusability of aluminum profile screws is generally limited.

Each disassembly and reinstallation of the screws can cause wear and damage, reducing their performance and reliability.

Here are some considerations regarding the reusability of aluminum profile screws:

Wear Inspection

Before reusing screws, carefully inspect the surface and threads for any noticeable wear or damage.

If significant damage or deformation is present, it is advisable to replace the screws with new ones.

Torque Control

When re-tightening the screws,

use the correct torque tool and appropriate torque value to avoid over-tightening or under-tightening.

Excessive torque can lead to material fatigue or thread damage.

Rust Prevention

Aluminum profile screws have good corrosion resistance, but they may be susceptible to oxidation or corrosion after disassembly.

It is recommended to clean and apply rust prevention treatment to the screws before reuse, extending their lifespan.

Regular Inspection

Regularly inspect the condition of aluminum profile screws,

especially in applications exposed to harsh environments or subjected to vibrations.

If any loose or damaged screws are found, replace them promptly to ensure the reliability of the connections.

These considerations highlight the importance of proper maintenance and inspection when reusing aluminum profile screws. By following these guidelines, you can help maximize their lifespan and ensure reliable performance in various applications. Regular inspection and maintenance are key to identifying any potential issues early on and addressing them promptly to prevent further damage or failures.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

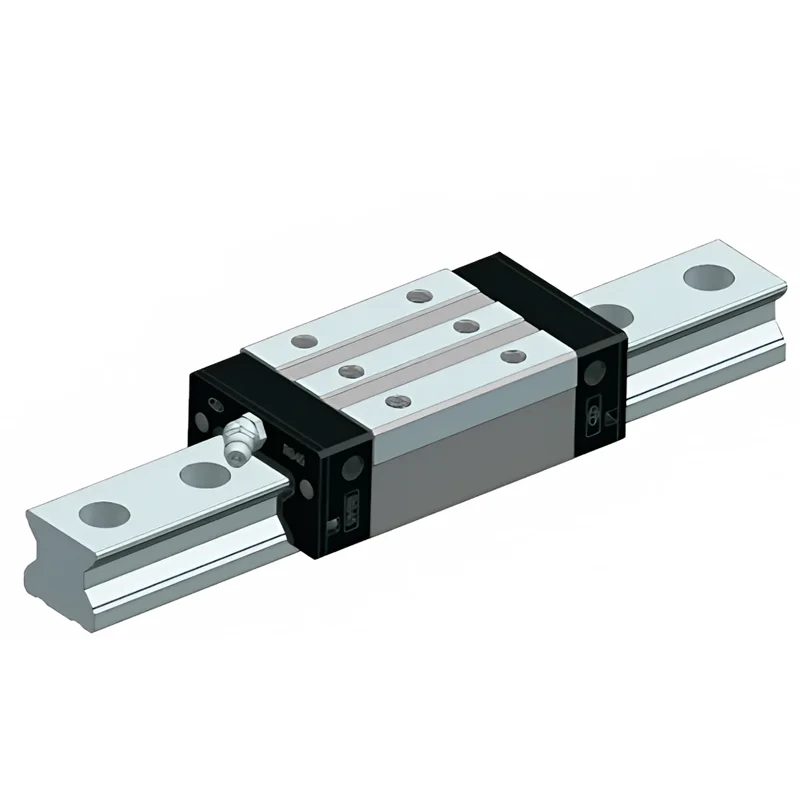

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

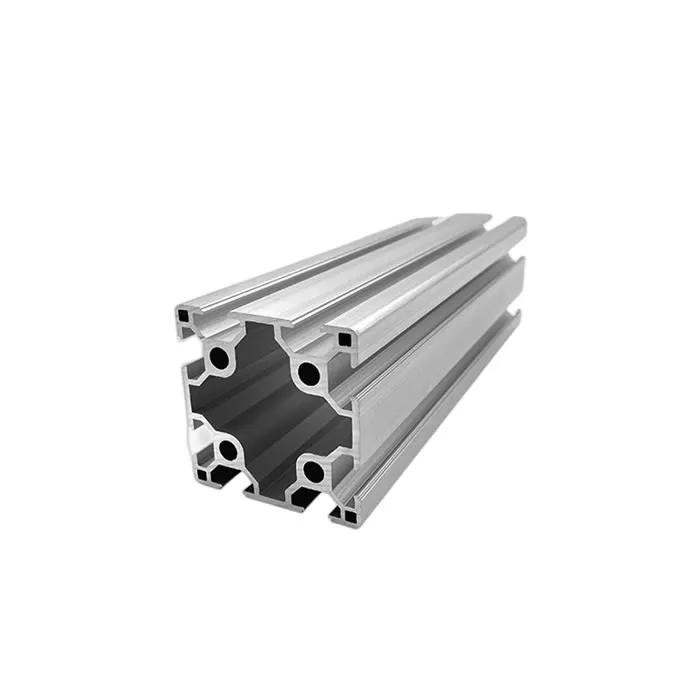

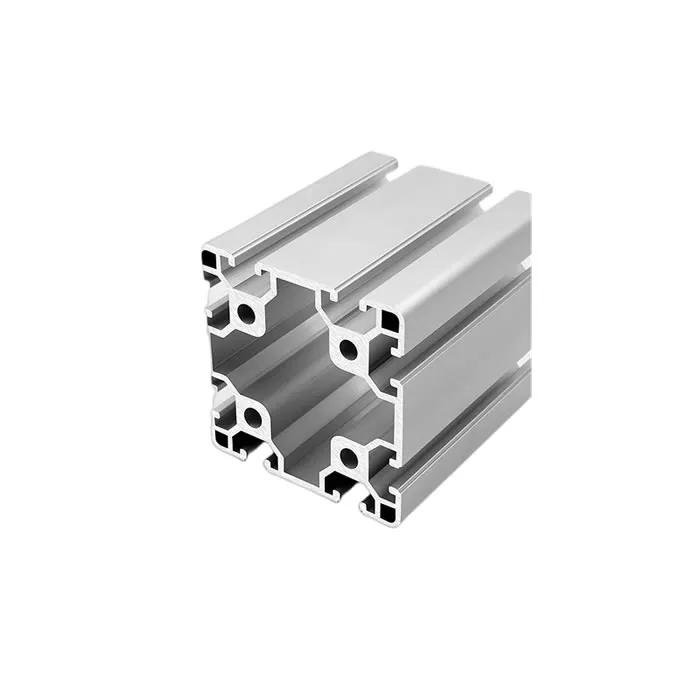

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS