Can aluminum profile screws be used in outdoor environments

Aluminum's inherent corrosion resistance makes it generally suitable for outdoor environments. This makes aluminum profile screws a practical solution for many outdoor projects.

Factors Affecting Corrosion Resistance:

However, some conditions can accelerate corrosion. These include:

High humidity

Acidic or alkaline environments (extreme pH levels)

Salt spray (common in coastal areas)

Enhancing Corrosion Resistance:

If your project involves any of these challenging conditions, consider these additional measures:

Stainless Steel Screws: Using stainless steel screws offers superior corrosion resistance compared to standard aluminum screws.

Surface Treatments: Applying surface treatments like anodizing or coating can further enhance the protective layer on the screws.

Maintenance Tips:

For long-lasting performance of aluminum profile screws outdoors:

Regular Inspections: Routinely check the screws for signs of corrosion, wear, or loose connections.

Proper Maintenance: Address any issues promptly. This might involve cleaning the screws, retightening them, or replacing corroded screws with appropriate alternatives.

By understanding these factors and implementing preventive measures, you can ensure aluminum profile screws function well and contribute to the longevity of your outdoor project.

How to avoid roller bearing failures

How to avoid roller bearing failures

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

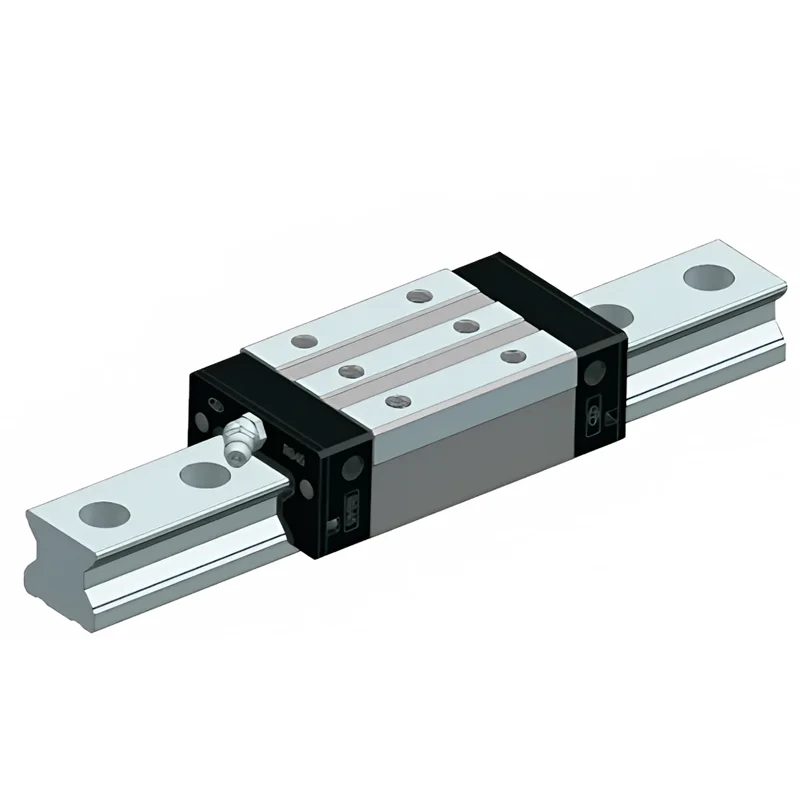

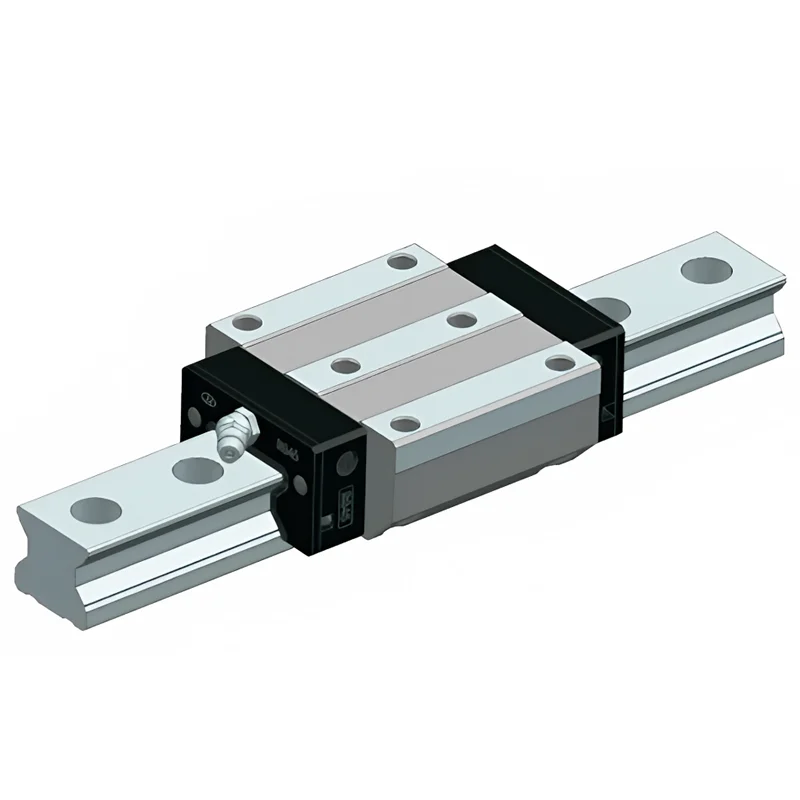

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

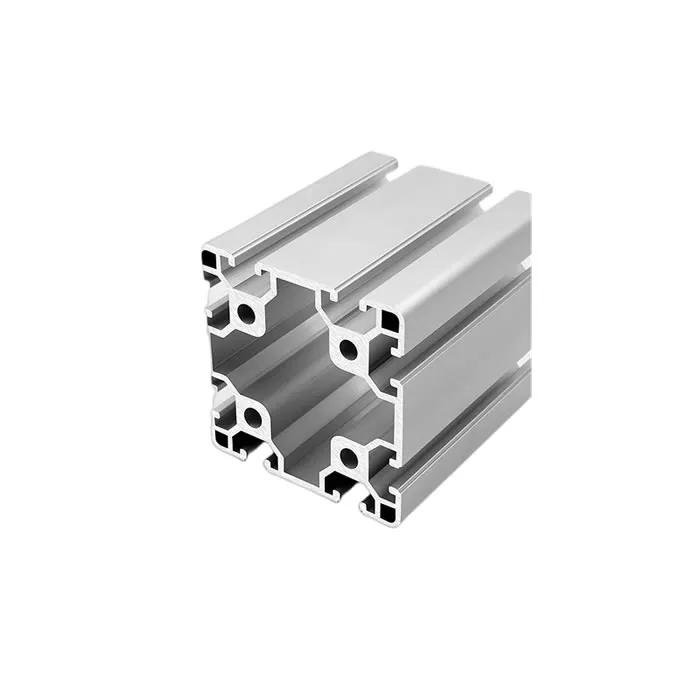

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd