How do you install Aluminum profile connectors

Prepare the profiles: Cut the aluminum profiles to the

desired length and ensure that the ends are free from burrs or sharp edges.

Align the profiles: Position the profiles to be joined,

ensuring proper alignment and orientation.

Insert the connector: Slide the Aluminum profile

connector into the T-slot or mounting groove of the profiles.

Secure the connection: Use bolts, screws, or specialized

fasteners to tighten the connection. Ensure that the fasteners

are appropriately sized and tightened to provide a secure and stable joint.

Some tips and considerations for installation include:

Follow the manufacturer's guidelines

and instructions for the specific connectors being used.

Use compatible tools, such as Allen wrenches or torque wrenches,

to ensure proper tightening without damaging the connectors or profiles.

Double-check the alignment before tightening the

fasteners to avoid misalignments or uneven connections.

Distribute the fasteners evenly along the

joint to ensure uniform load distribution.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

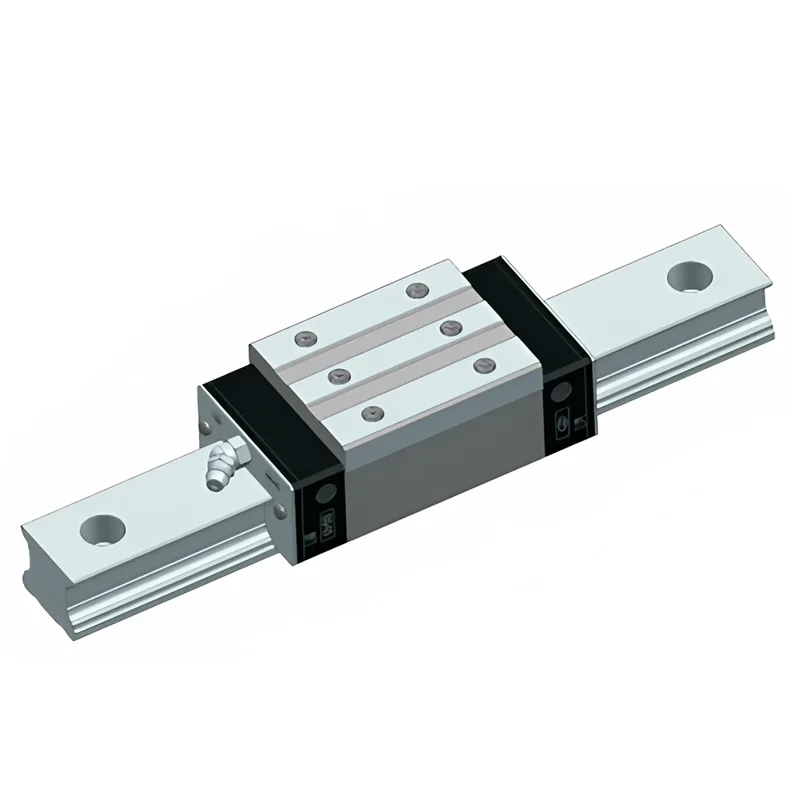

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS