How to choose the right material for Aluminum profile connectors

When selecting the material for Aluminum Profile Connectors,

several factors should be considered:

Load requirements: The material's strength and load-bearing

capacity should match the intended application to ensure structural stability.

Environmental conditions: If the connectors will be exposed

to corrosive environments or outdoor conditions, materials with enhanced corrosion

resistance, such as stainless steel or coated alloys, should be chosen.

Aesthetics: Depending on the desired appearance of the final structure,

materials with different finishes, colors, or surface treatments can be selected.

Compatibility: The connector material must be compatible with the aluminum

profiles being used in terms of size, shape, and malleability.

Common materials for Aluminum profile connectors include aluminum alloys

(such as 6061 or 6063), stainless steel,

and reinforced plastics (such as nylon or fiberglass-reinforced polymers).

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

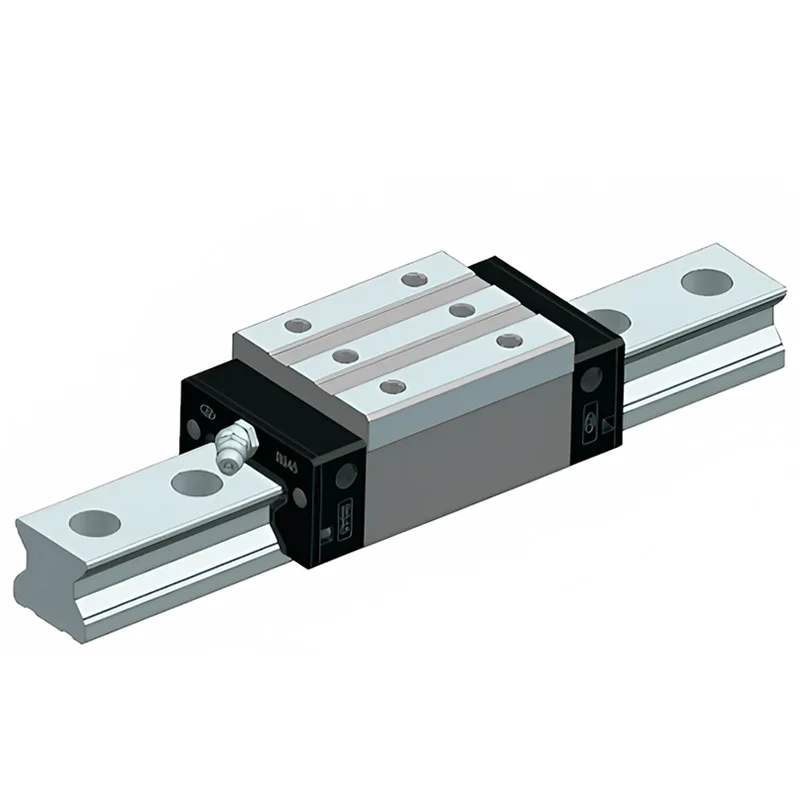

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS