Choosing the Right Industrial Aluminum Profiles for Your Needs

Industrial aluminum profiles are the workhorses of countless industries, from construction and automotive to food processing and aerospace. Their versatility stems from the inherent properties of aluminum: durable, lightweight, corrosion-resistant, and readily machinable. However, with such a variety available, selecting the ideal profile for your specific application requires careful consideration. Here's a comprehensive guide to ensure you make the best choice:

Understanding Your Needs

The first and most crucial step is identifying your project's requirements. Ask yourself:

What is the intended use of the profile? Is it for a load-bearing structure in construction, a decorative element in furniture, or a component in a food processing line?

What level of hardness is necessary? Construction projects may require high-strength profiles for safety, while some food processing applications might necessitate softer profiles for gentle product handling.

Will the profile be exposed to harsh environments? If so, corrosion resistance becomes a vital factor. Consider factors like weather elements, chemicals, or saltwater exposure.

Does the profile need machining or welding? Certain profiles are designed for easier cutting, shaping, and joining techniques to streamline your manufacturing process.

Key Selection Criteria

Once you have a clear understanding of your project needs, delve deeper into the following aspects of the profiles:

Hardness: Aluminum profiles come in varying degrees of hardness, measured on the Brinell hardness scale (HB). Select a profile with the appropriate hardness to ensure structural integrity and safety.

Load Bearing Capacity: This refers to the profile's strength and its ability to withstand weight. The required strength will differ depending on the application. Beams in buildings need high load-bearing capacity, while profiles for shelving may require less.

Corrosion Resistance: Aluminum naturally forms a protective oxide layer that resists corrosion. However, specific environments might necessitate profiles with enhanced resistance. Look for profiles treated with special coatings or alloys formulated for superior corrosion protection.

Machinability: If your project involves extensive cutting, drilling, or shaping, choose profiles known for their machinability. This translates to better working efficiency and reduced production time.

Weldability: Profiles destined for welding applications need to be compatible with welding techniques. Opt for weldable profiles that can withstand the heat of the process without compromising their integrity.

Additional Considerations

Beyond the technical specifications, consider these factors for a smooth and successful project:

Manufacturer Reputation: Choose a reputable manufacturer with a proven track record of quality and customer satisfaction. Look for companies with experience in your specific industry for better understanding of your needs.

Quality and Cost: While cost is a factor, prioritize quality. High-quality profiles ensure the safety and longevity of your finished product. Compare various manufacturers to find a balance between affordability and quality.

Product Variety and Service Delivery: A leading manufacturer will offer a diverse range of profiles to cater to different applications. Customization options are also beneficial for projects with unique requirements. Additionally, prioritize manufacturers with responsive customer service to address any inquiries or concerns.

Conclusion

By understanding your project needs and carefully considering the key selection criteria, you can make an informed choice when selecting industrial aluminum profiles. Remember, the right profile ensures the structural integrity, functionality, and ultimately, the success of your finished product. Don't hesitate to invest in quality; it's a worthwhile choice for the safety and longevity of your creation.

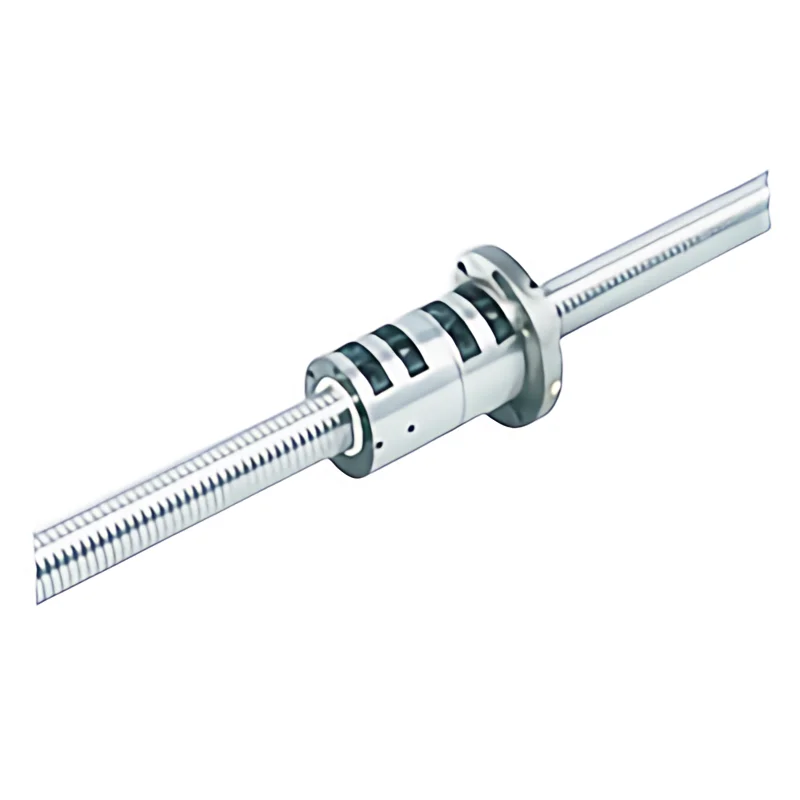

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

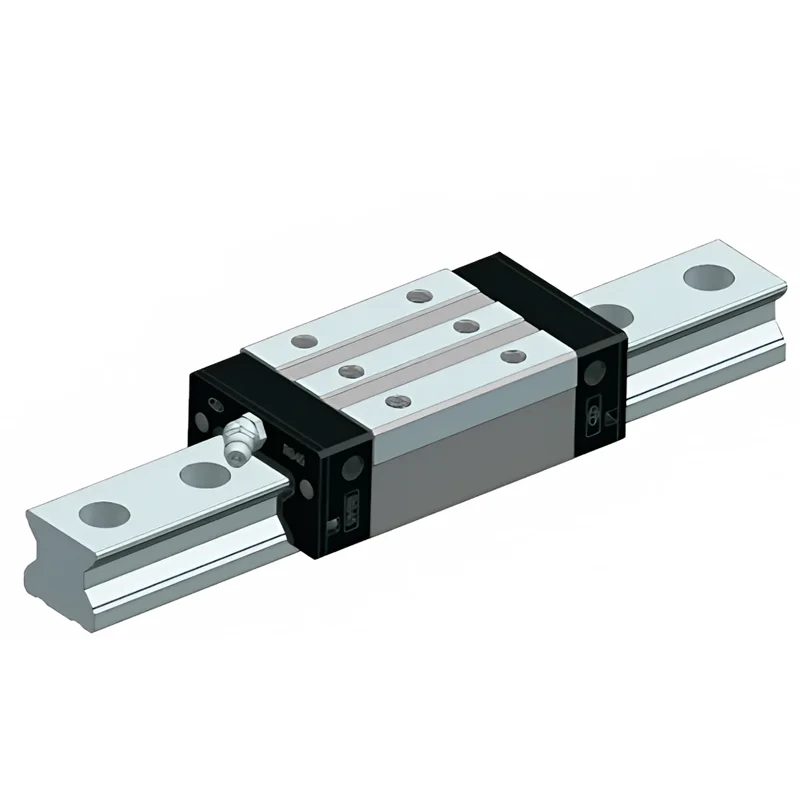

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

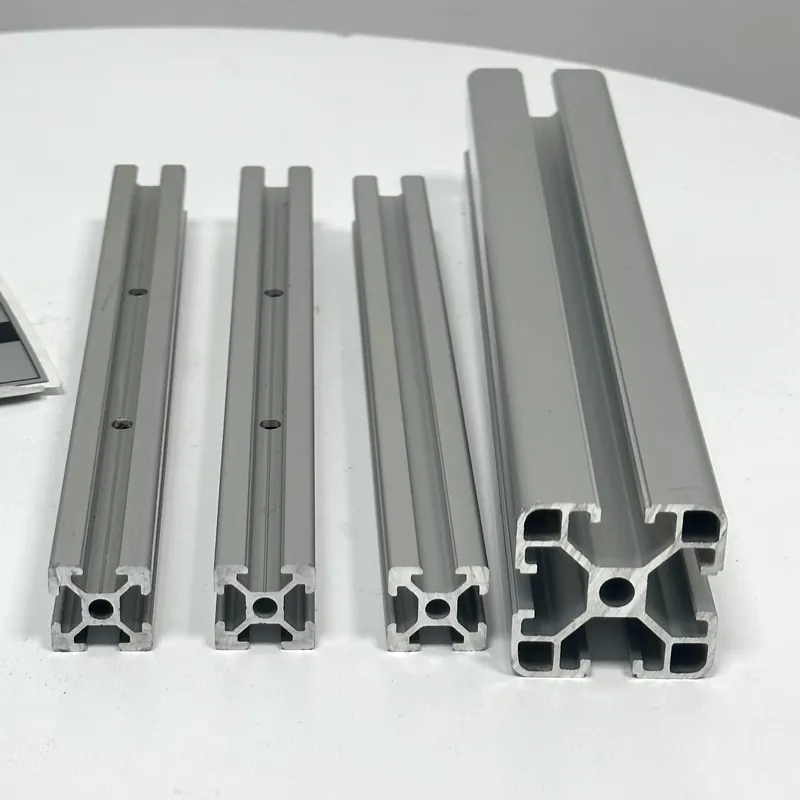

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS